Wide material splicing system and method

A splicing system, wide-width technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

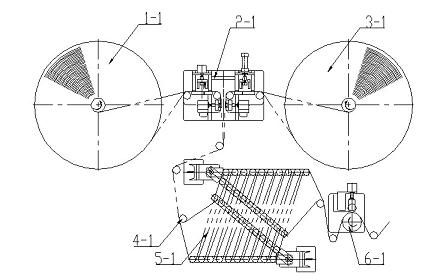

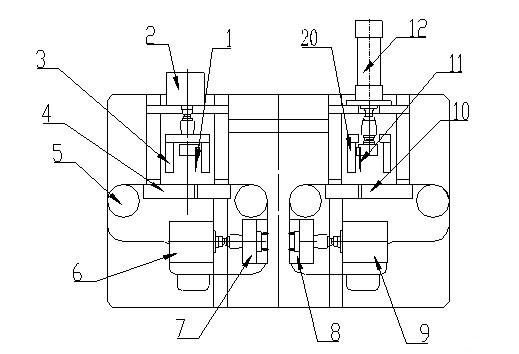

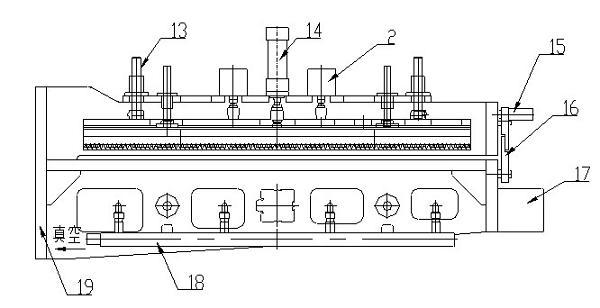

[0012] Embodiment 1: with reference to attached Figure 1~4 . A 600-1100mm wide material splicing system, which includes a material receiving part and a material cutting part. The material receiving part is divided into a left part and a right part. The left part is composed of a set of cylinder actuators and a material receiving box A7 , the cylinder actuator consists of a material receiving cylinder A6 plus two sets of linear bearings and guide rods connected to the material receiving box A7. The material receiving cylinder A6 and the material receiving box A7 are connected through a floating joint to ensure that the material receiving cylinder A6 is pushed and pushed , the entire set of actuators runs flexibly and smoothly. The material receiving box A7 is hollow inside and connected to the branch pipe 18 at the back through the air pipe. The surface of the material receiving box A7 is covered with a layer of silica gel, and there are three rows of suction holes on it for a...

Embodiment 2

[0023] Example 2: On the basis of Example 1, the splicing method of 600-1100mm wide material, assuming that the material roll on the left is working normally, and the material roll is almost finished, it needs to be replaced with the right material roll. The material roll is ready, pull out the positioning handle 15 on the right side, put down the safety rocker arm 16 on the right side, pull the material on the right side to pass through the transition wheel and bed knife plate B10 on the right side, and put the material on the right side Align the splicing tape with the air suction hole on the material receiving box B8, press the right ready button on the right button box 17, open the solenoid valve 4B, and the vacuum generator B will generate a vacuum, so that the material receiving box B8 will generate suction to remove the materials on the right side. And the splicing material is sucked on it, pull up the safety rocker arm on the right side, press the right refueling button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com