Process for depositing organic materials

一种沉积装置、有机薄膜的技术,应用在金属材料涂层工艺、对表面涂布液体的装置、涂层等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

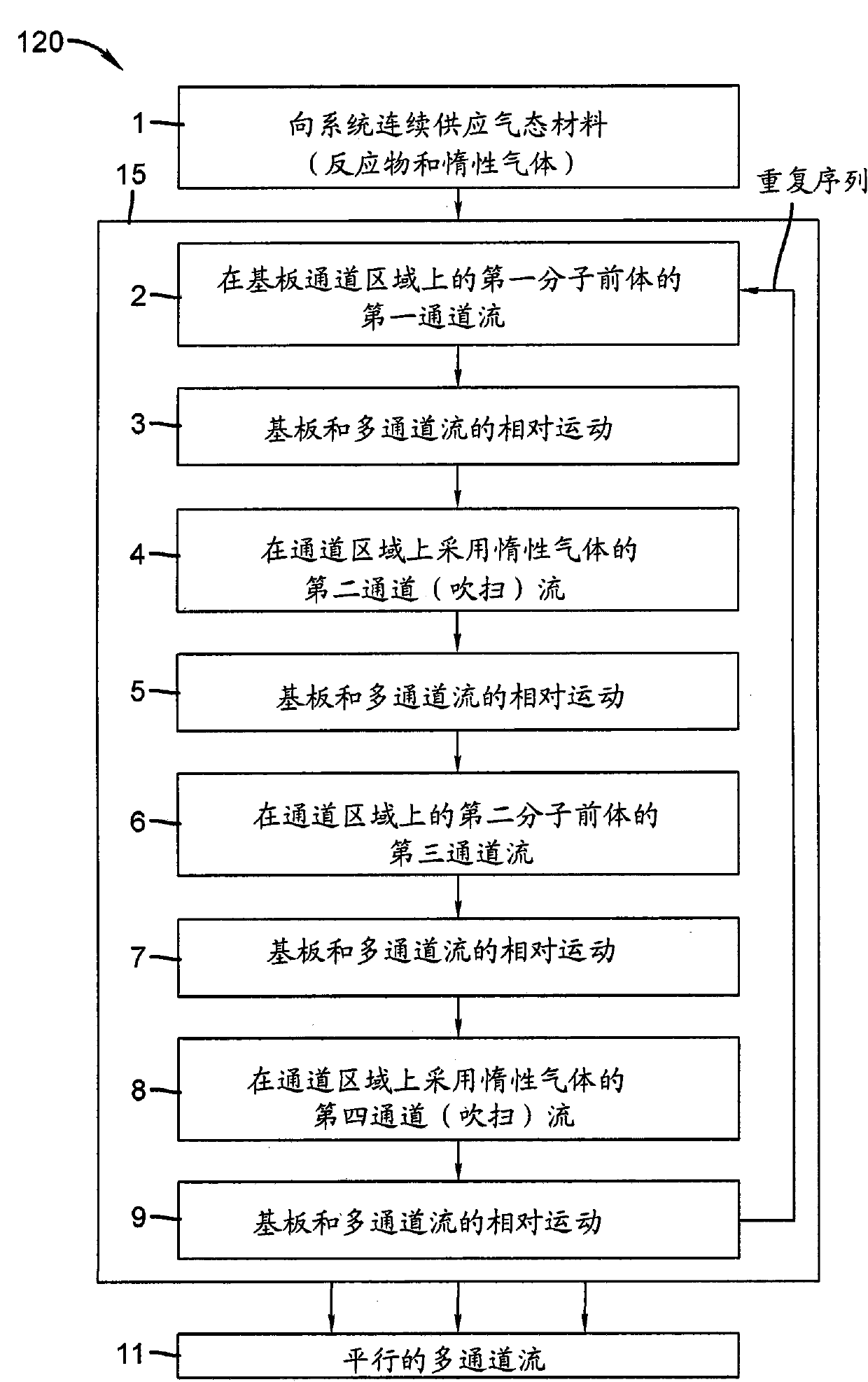

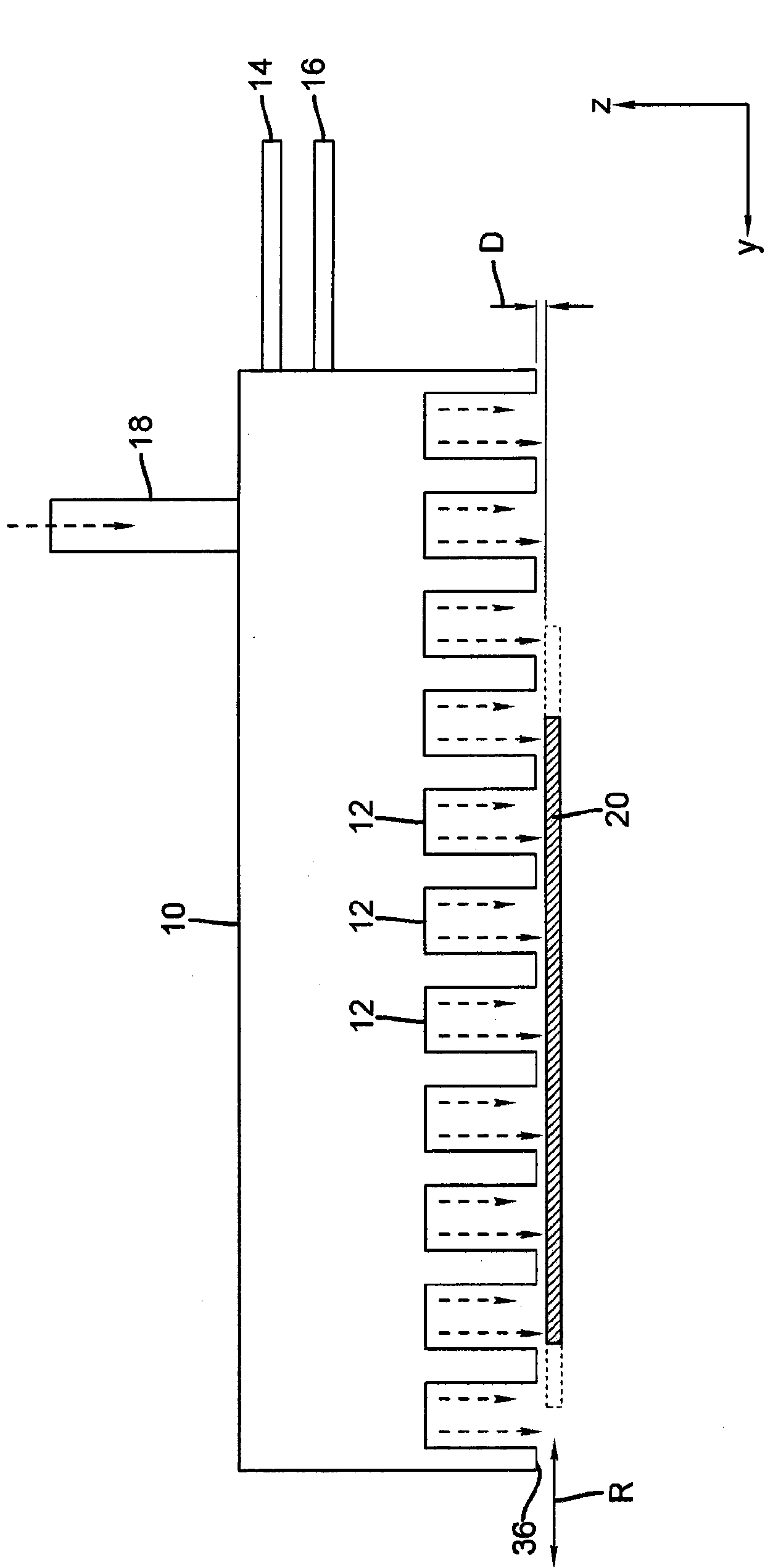

Method used

Image

Examples

Embodiment 1

[0134] Alucone, preparation of an organic-containing thin film

[0135] This example describes the preparation of alucone, a thin film containing a significant amount of organic material. For this deposition, bubbler 82 contained trimethylaluminum as the O2 precursor and bubbler 84 contained ethylene glycol as the O1 precursor.

[0136] A 2.5 x 2.5 inch square (62.5 mm square) silicon wafer was placed on the platen of the apparatus, held in place by a vacuum and heated to 200°C. The platen with the substrate is positioned below the coating head directing the flow of reactive gas. The distance between the silicon substrate and the coating head was adjusted to 30 microns using a micrometer.

[0137] The applicator head was maintained at 40°C. The flow rate of a single gas, shown in Table 1 below, caused the coating head to vibrate across the substrate for the specified number of cycles to initiate the coating process.

[0138] Table 1

[0139] sample

flow ...

Embodiment 2

[0143] Preparation of Borcone

[0144] Borocone can be formed using ALD or molecular layer epitaxy. This hypothetical example describes the preparation of borocone, a thin film containing a significant amount of organic material. For this deposition, bubbler 82 contained trimethyl borate, B(OMe) as O precursor 3 , bubbler 84 contains ethylene glycol as O1 precursor.

[0145] The apparatus used for the preparation of borocone was the same as that described in Example 1. A 2.5 x 2.5 inch square (62.5 mm square) silicon wafer was placed on the platen of the apparatus, held in place by a vacuum and heated to 200°C. The platen with the substrate is positioned below the coating head directing the reactive gas flow. The distance between the silicon substrate and the coating head was adjusted to 30 microns using a micrometer.

[0146] The applicator head was maintained at 40°C. The substrate was maintained at 30°C-250°C. The desired borocone thickness can be obtained by contr...

Embodiment 3

[0151] Preparation of polyurethane

[0152] In another hypothetical embodiment of the present invention, polyurethane thin films can be formed using ALD or molecular layer epitaxy. This example describes the preparation of a polyurethane film, a thin film containing a substantial amount of organic material. For this deposition, bubbler 82 contained 1,4-butanediol as the O2 precursor and bubbler 84 contained 1,4-diisocyanatobutane as the O1 precursor.

[0153] The apparatus used to prepare polyurethane films was the same as that described in Example 1. A 2.5 x 2.5 in2 (62.5 mm2) silicon plate was placed on the platen of the apparatus, held in place by vacuum and heated to 200°C. The platen with the substrate is positioned below the coating head for directing the reactive gas flow. The distance between the silicon substrate and the coating head was adjusted to 30 microns using a micrometer.

[0154] The temperature of the applicator head was maintained at 40°C. The substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com