Flexible object thickness measuring device

A thickness measurement and flexible object technology, applied in the field of film thickness measurement, can solve the problems of difficulty in ensuring the accuracy of measurement data, inconvenient use, low measurement efficiency, etc., to improve consistency and continuity, facilitate installation, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

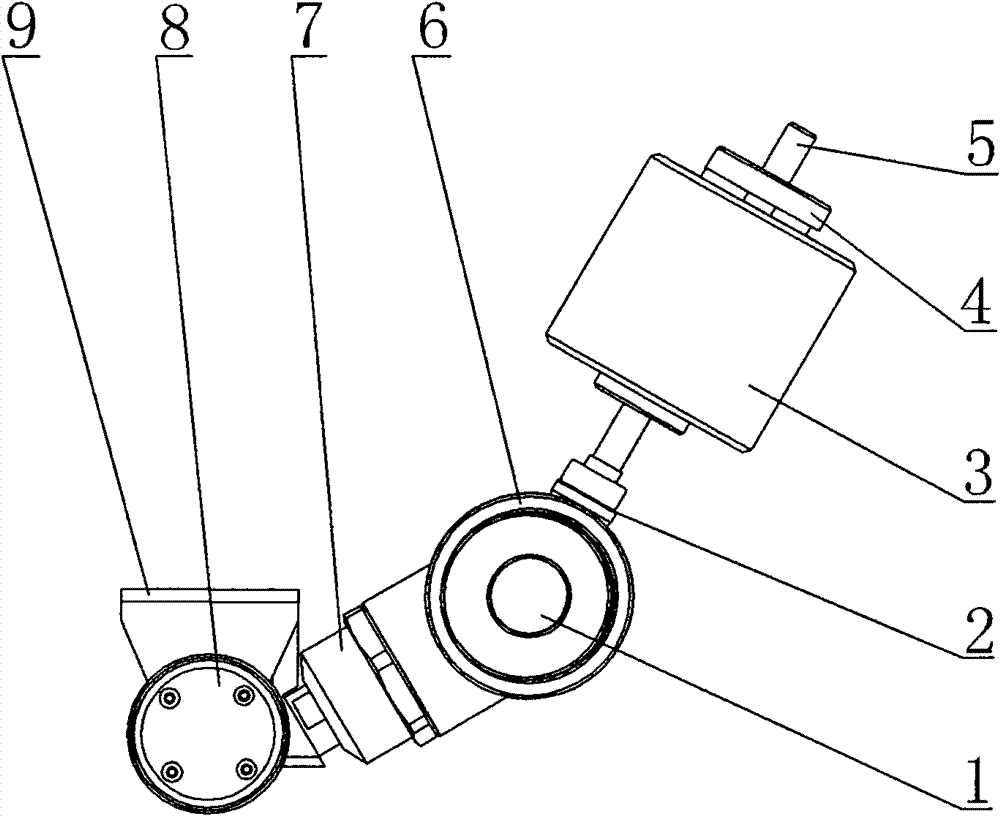

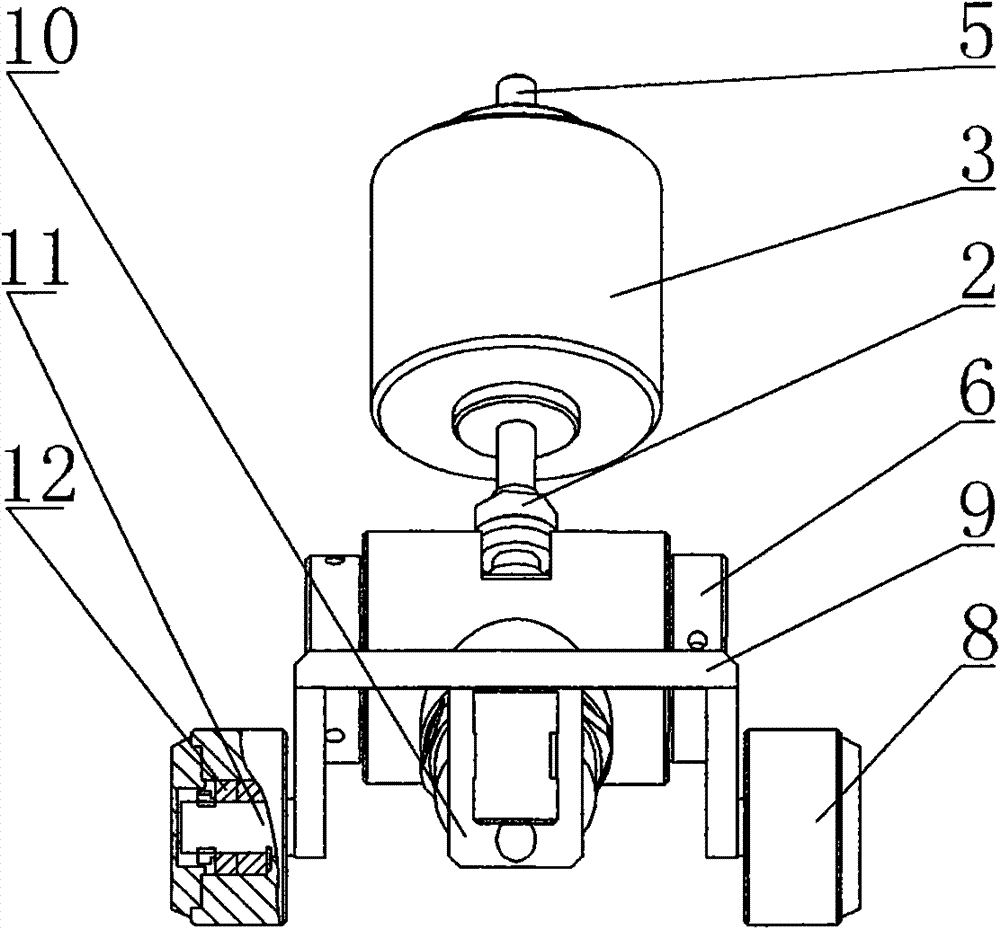

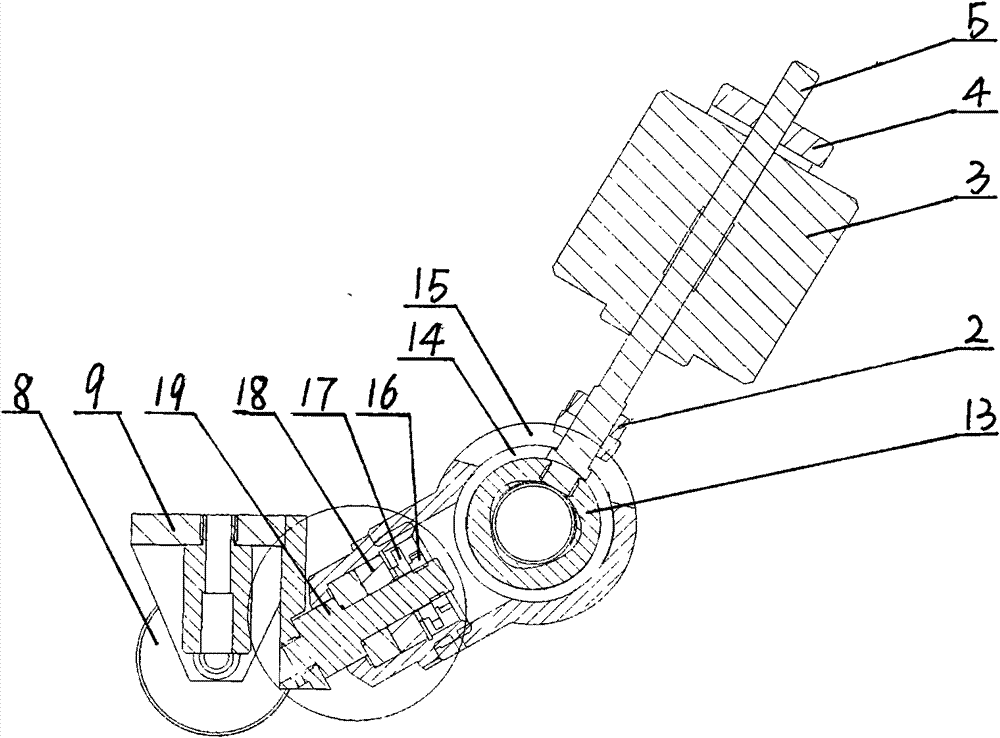

[0019] The present invention comprises roller 8, and the bottom side of wheel frame 9 between the shaft 11 of roller 8 is fixed with connecting rod 19, and connecting rod 19 is fixed on the inner ring of bearing 18 at the bottom of rotor body 7; Wheel carrier 9 is provided with The sensor connection frame 10, the tail thread of the connecting rod 19 are provided with a positioning ring 17 and a fastening nut 16, and the positioning ring 17 is provided with a positioning groove 20 corresponding to the pin 21 on the rotor body 7; above the rotor body 7 is The support sleeve 6 of the fixed shaft 1 ; the fixed shaft 1 is provided with a screw 5 with a counterweight 3 , and an opening 15 is provided where the support sleeve 6 passes through the screw 5 .

[0020] A bearing 12 is arranged between the roller 8 and the shaft 11 to reduce the friction between the roller 8 and the measured object 22 and avoid affecting the measurement accuracy.

[0021] A magnetic eddy current sensor ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com