Automobile hub combined oil seal

A technology combining oil seals and automobile hubs, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of easy movement, hub oil leakage, poor coaxiality of oil seals, etc., and achieve good coaxiality, oil seals Reasonable structure, not easy to move left and right

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

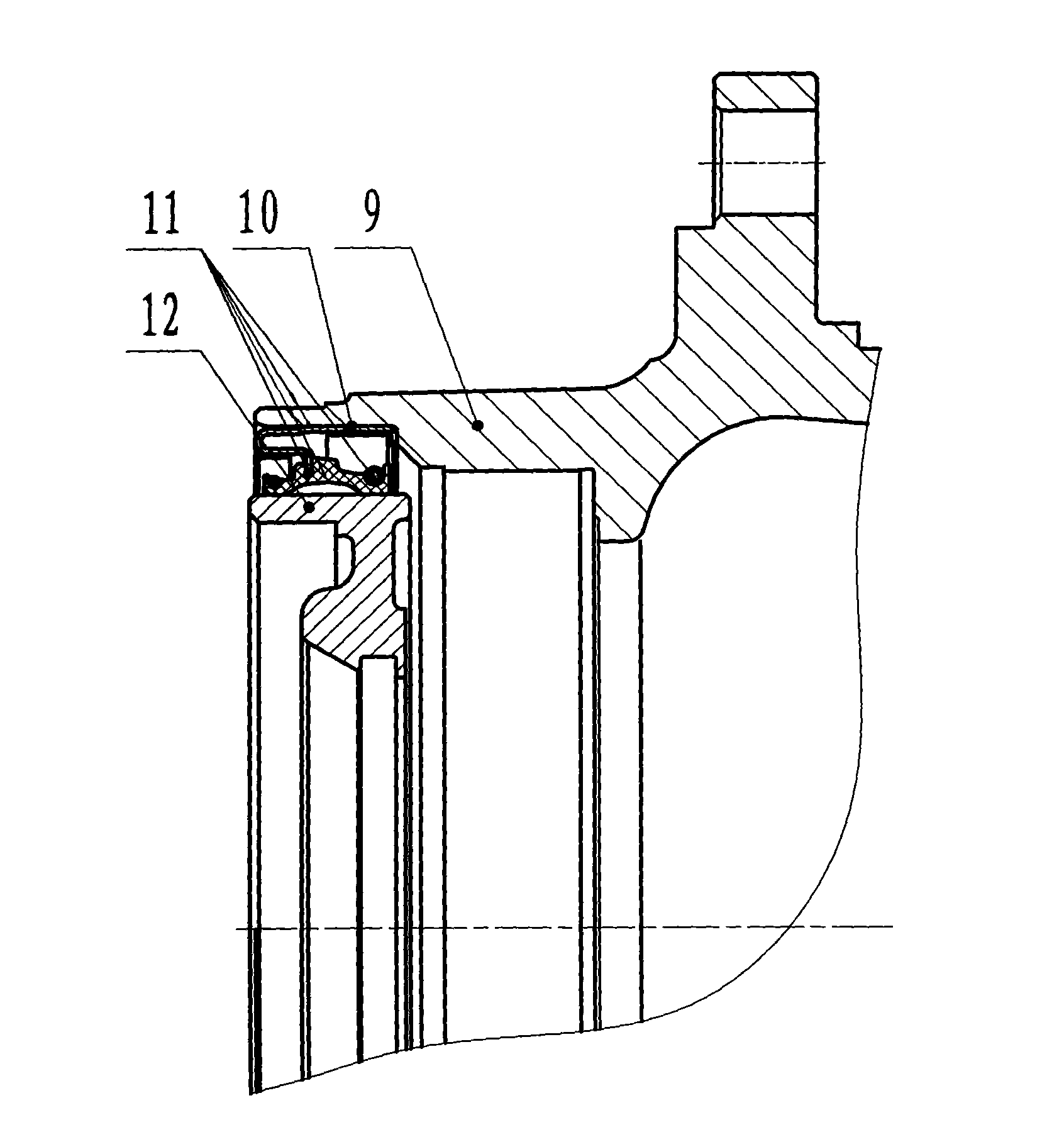

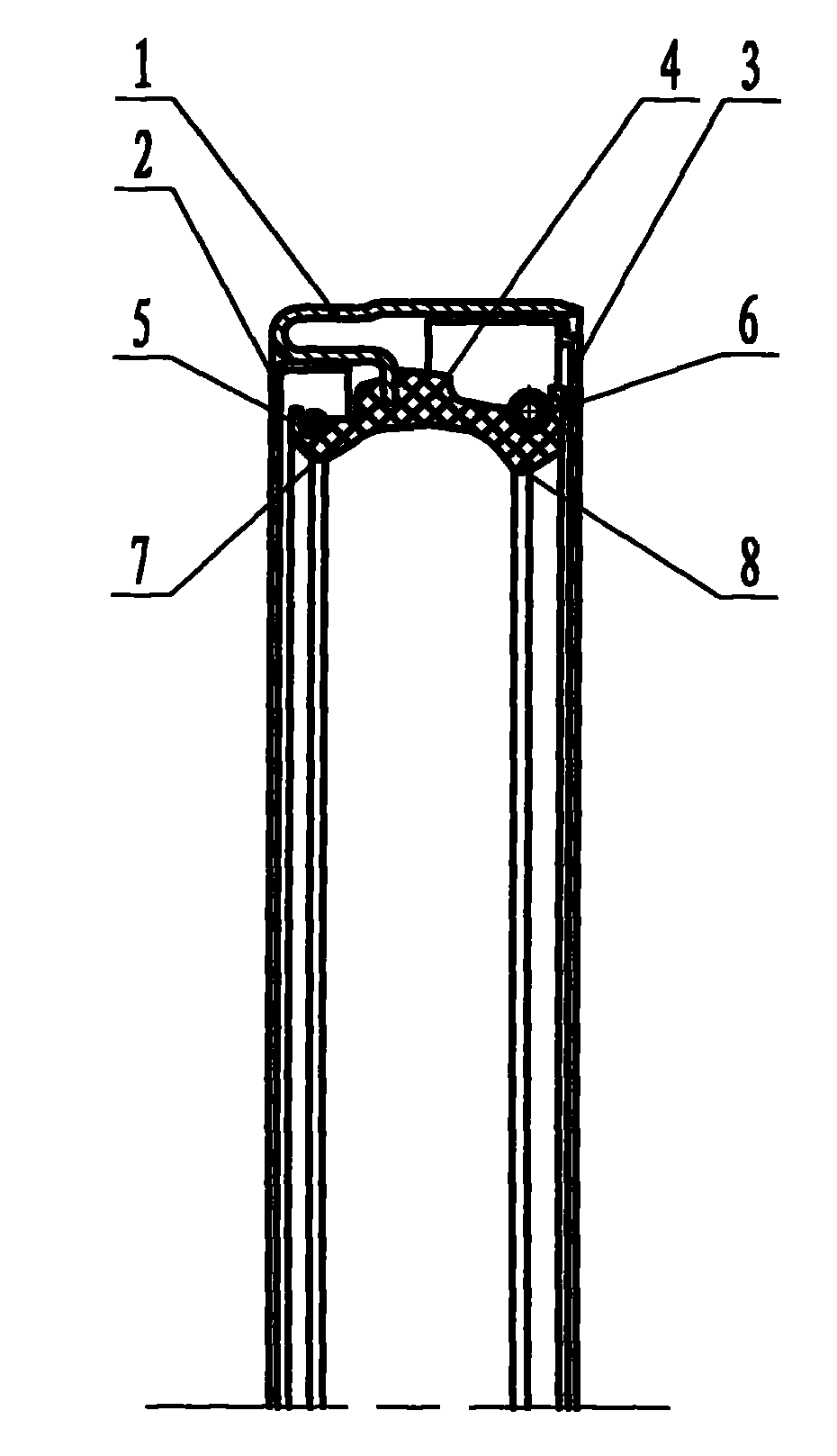

[0012] Depend on figure 1 , figure 2 It can be seen from the figure that: an automobile hub combined oil seal is characterized in that the automobile wheel combined oil seal is mainly composed of an oil seal frame, a sealing ring 4 and a spring ring, wherein the oil seal frame is mainly composed of a main frame 1, a left supporting frame 2, and a right supporting frame The skeleton 3 is composed of three parts. The main skeleton 1 is a thin steel stamping part with a smooth surface. The body is short (narrow), and the diameter of the left part of the outer ring body of the main skeleton 1 is small and inwardly shaped, and the right end section of the inner ring body of the main skeleton 1 is a vertical ring body bent down at a right angle. The lower surface of the left part of the inner ring body of 1 is press-fitted or welded to form a right-angled annular left support frame 2, and the left vertical ring surface of the left support frame 2 and the U-shaped curved end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com