Method for transferring hoisting-point loads

A transfer method and point load technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as large safety, transfer, and hidden dangers, and achieve good results, high safety factors, and strong economical practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

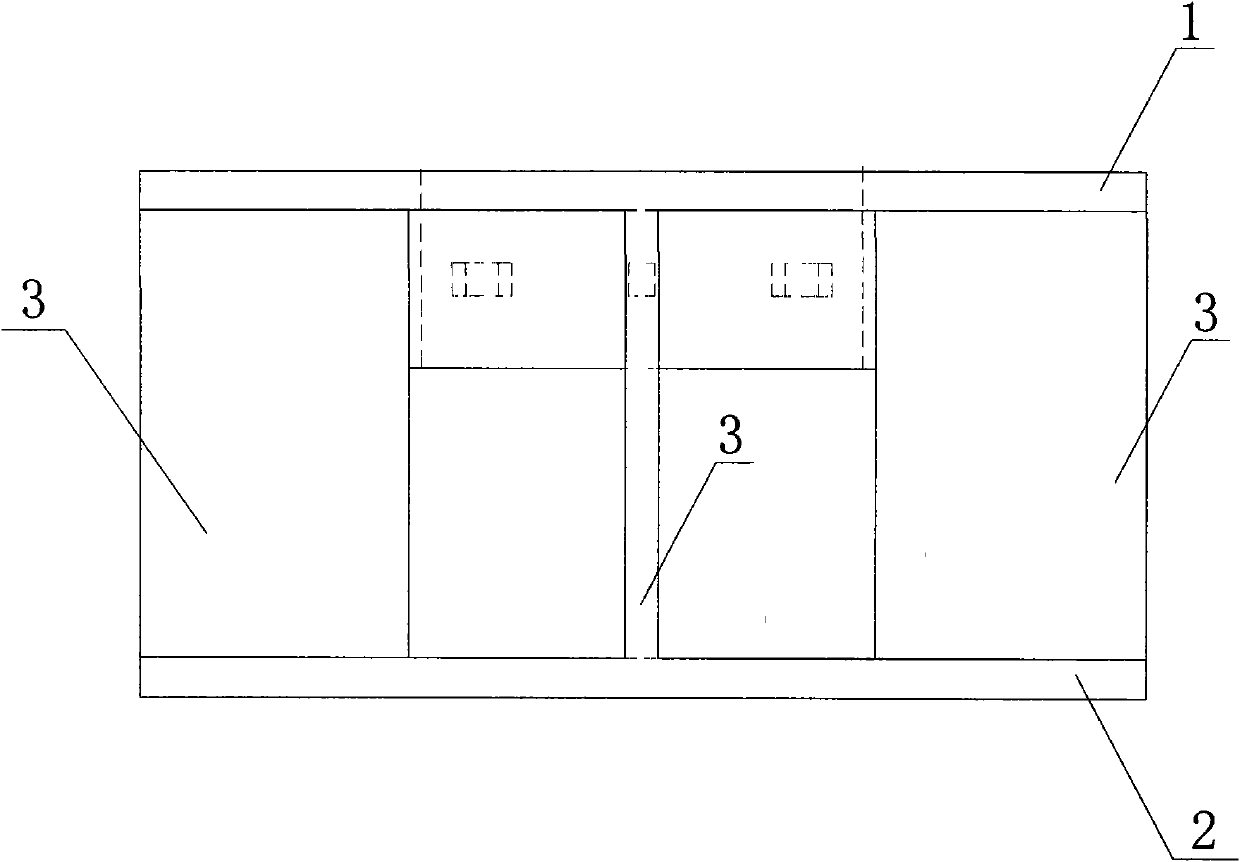

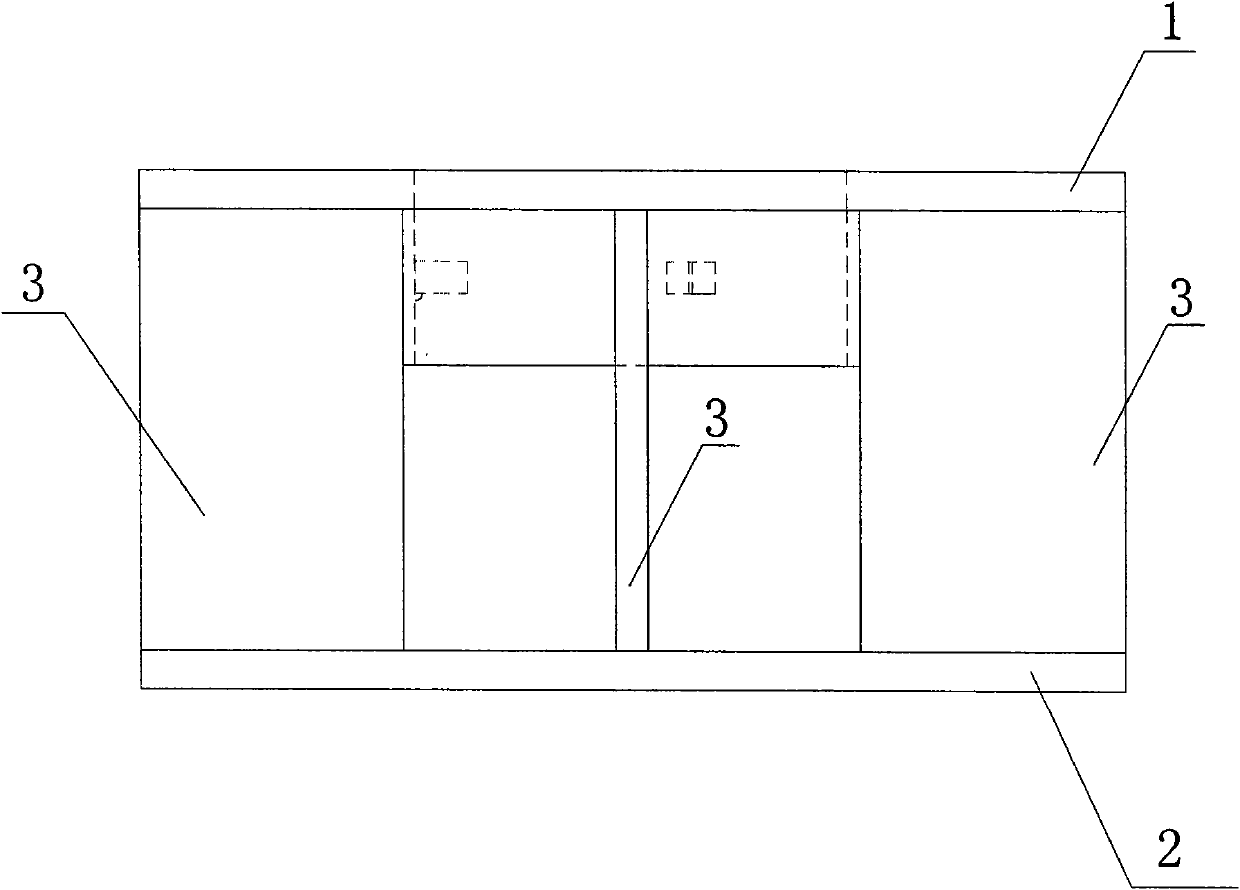

[0018] Now a hangar needs to be hoisted. The hangar is a double-layer grid structure with a bottom-hung gate truss. The lifting is divided into two steps: After the overall assembly of the grid frame and the upper part of the truss is completed, the first lift is started. When the bottom layer of the grid frame is 6m away from the bottom surface, the lifting is stopped, each lifting point is locked, and the installation of the hanging truss is started. After the completion, the lifting point at the truss is transferred from the bottom of the upper truss to the bottom of the lower truss. After the transfer of the lifting point is completed, the second lifting is started, and the whole network frame is directly raised to the design elevation.

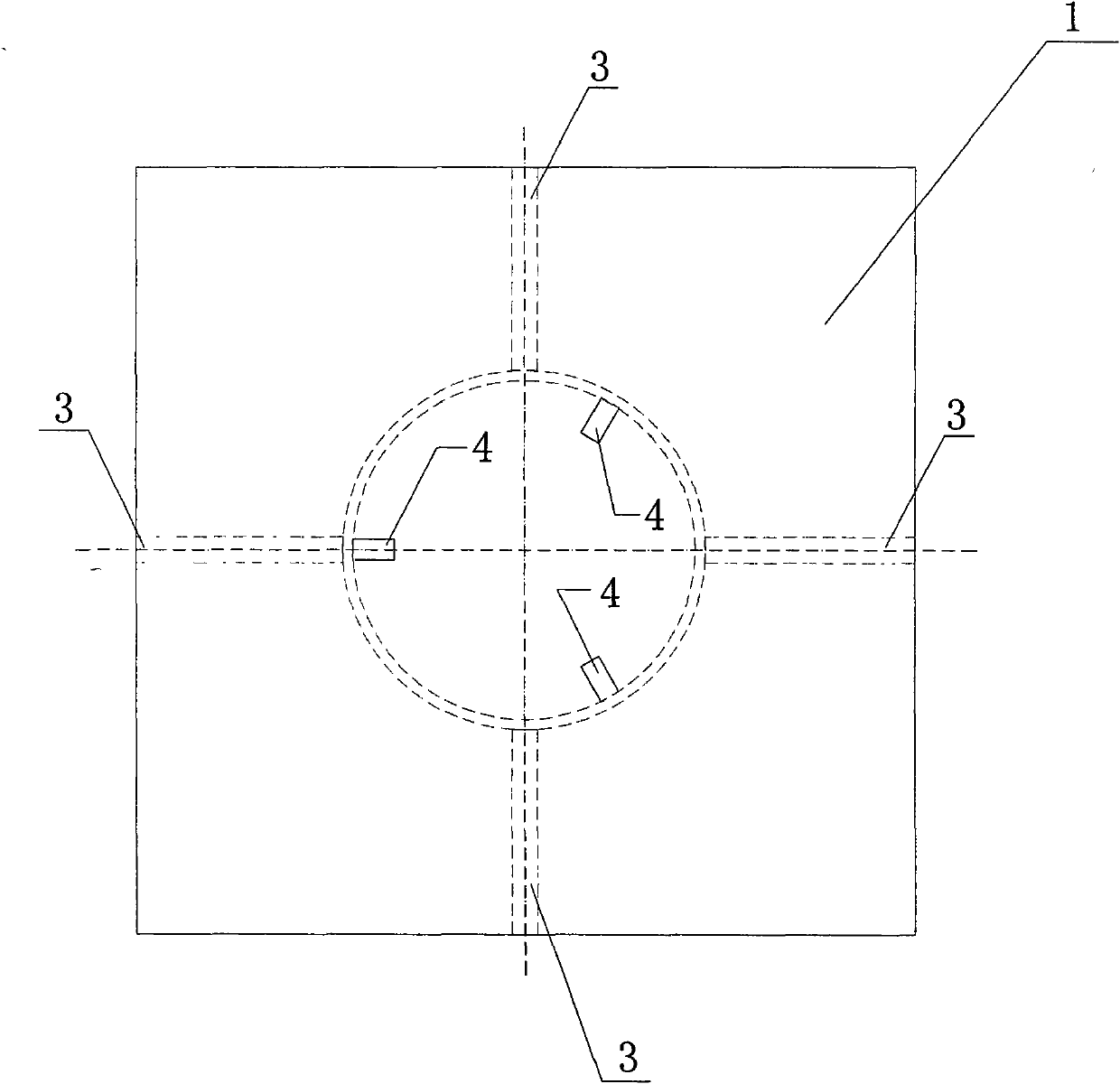

[0019] The load of the lifting point of the grid frame is transferred from the bottom of the upper truss to the bottom of the lower truss. At this time, it is the load transfer of the lifting point. The load transfer method of the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com