Molding box slip device

A sand box and unboxing technology is applied in the field of unboxing devices, which can solve the problems of not being too fast and the castings being scrapped, and achieve the effect of avoiding scrapping and meeting the speed requirement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

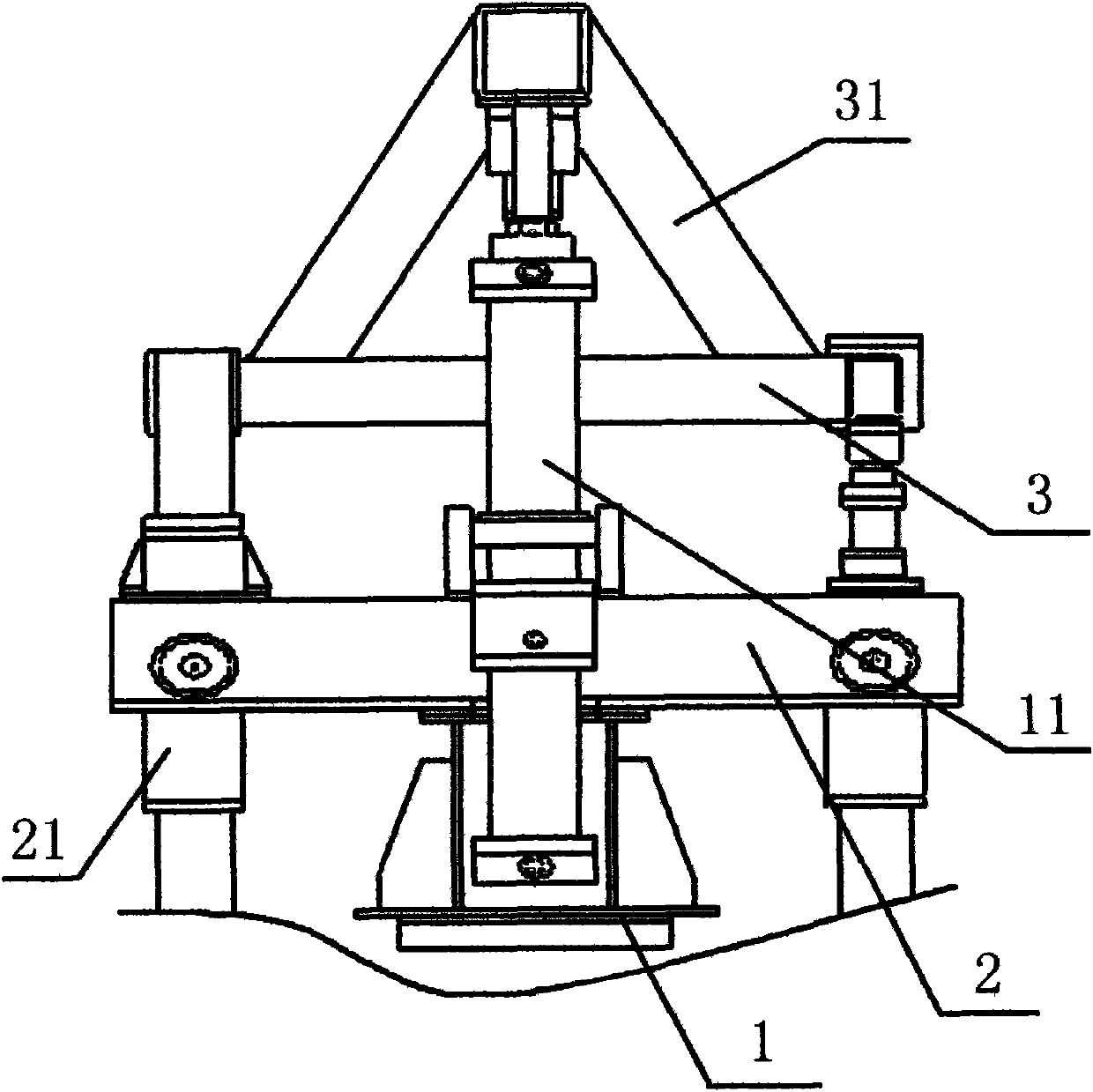

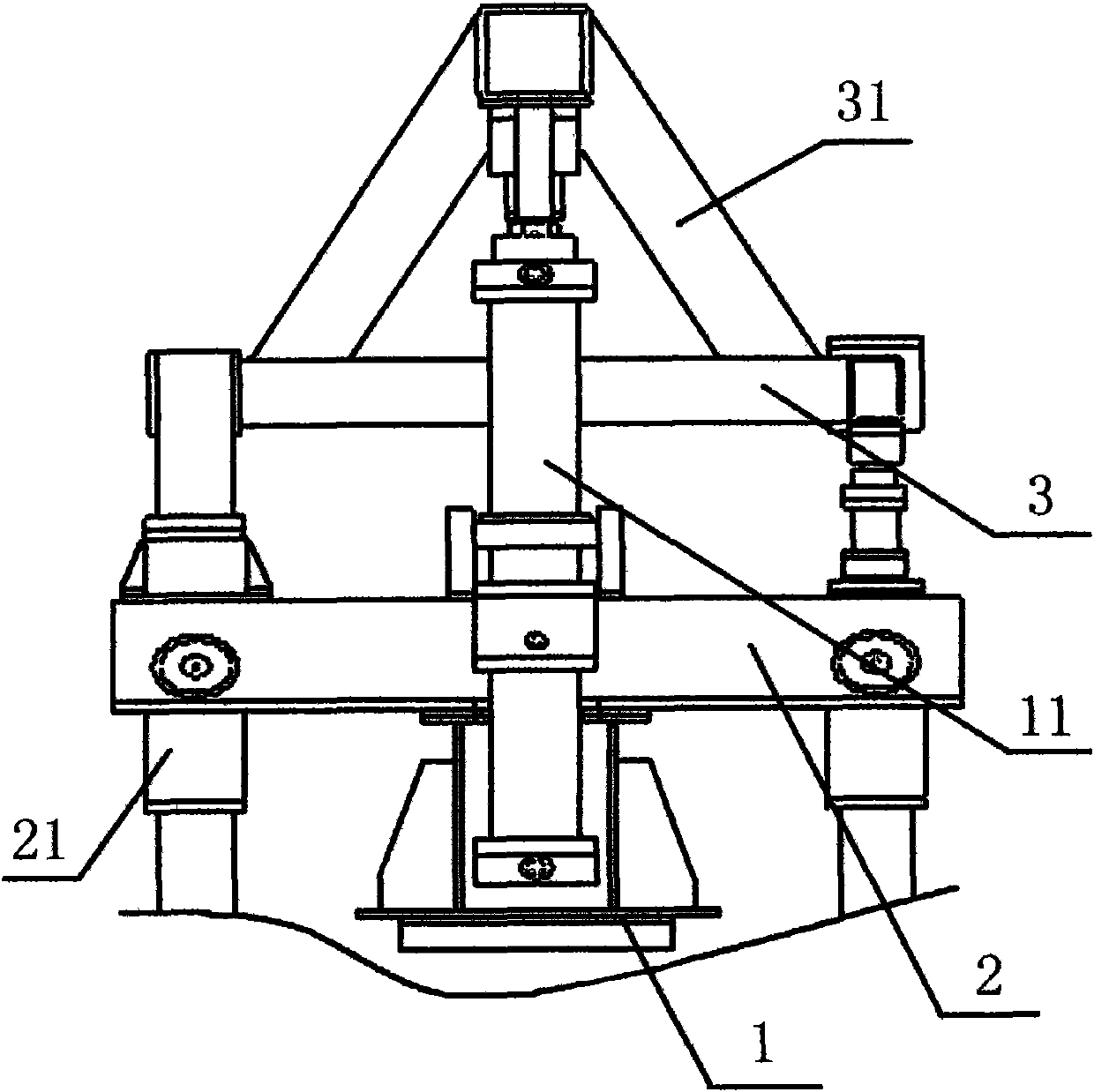

[0015] As shown in the sand box unboxing device, the left and right ends of the manipulator 2 are respectively equipped with a clamping arm 21, and the two clamping arms can complete the clamping of the sand box when they cooperate with each other, and complete the "holding" operation , the "tight" sand box, through the action of the head 1, the sand tires and castings stuck in the sand box will be dropped, and then the sand tires and castings will be dropped on the vibration shakeout machine for subsequent operations.

[0016] There is a hydraulic lifting cylinder 11 connected to the rear of the poking head 1. Under the control of hydraulic pressure, the poking head 1 can apply force to the workpiece to be poked, and through the action of the synchronous frame 3 and its connecting rod 31, the lifting cylinder 11 is pushed and The clamping of the clamping arm of the manipulator is interlocked, that is, when the lifting cylinder 11 pushes the poking head forward, the two clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com