Stator of an electronically commutated rotor motor

A technology of electronic commutation and electric motors, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as torque vibration, occupation, and unstable operation of the motor, and achieve the effect of reducing the working current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

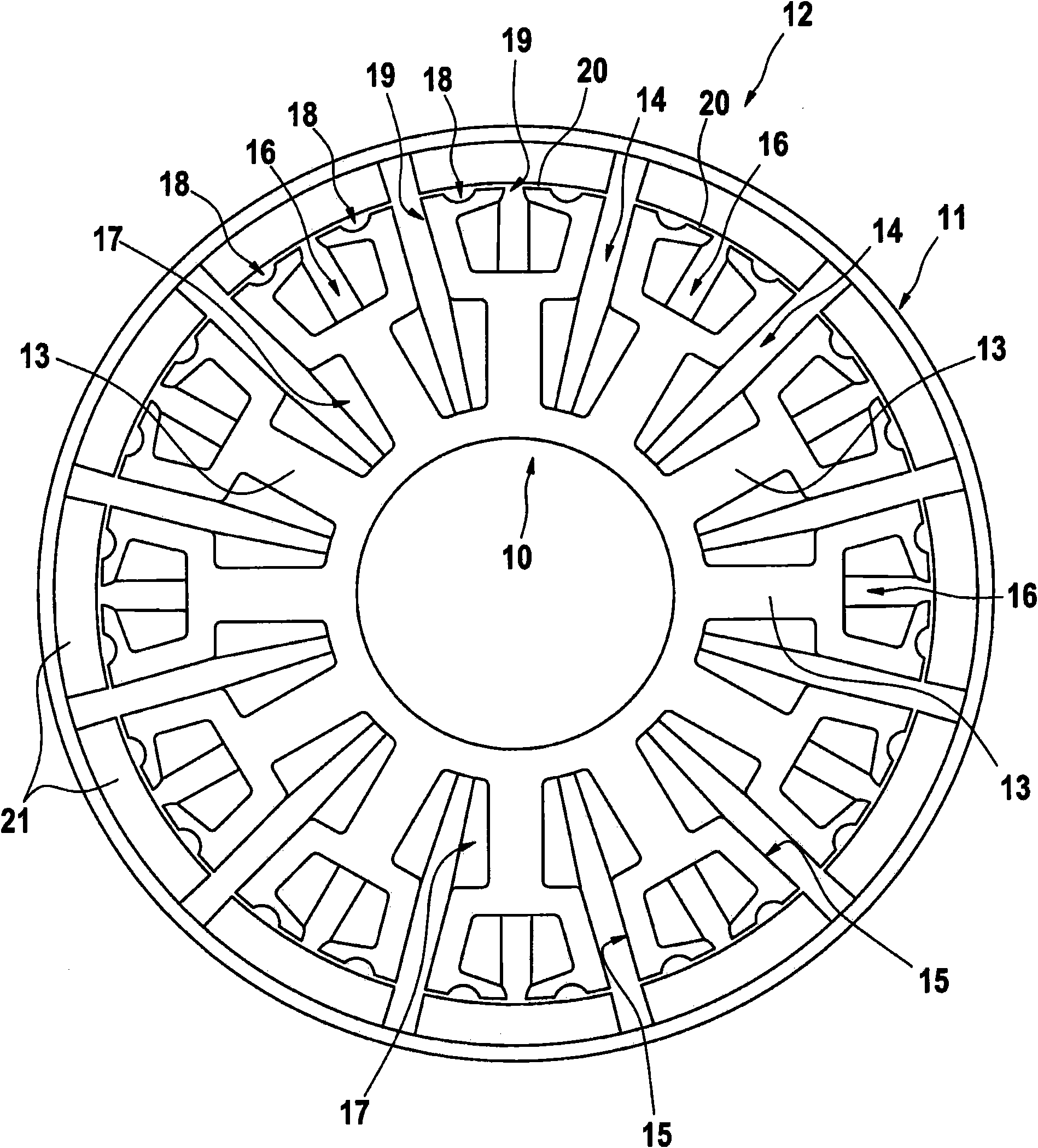

[0017] In this figure, the stator 10 and the rotor 11 of an electronically commutated rotor motor 12 are shown in a sectional view corresponding to the sheet metal section. The stator 10 is provided with a number of poles 13 which are separated from one another by grooves 14, in particular winding spaces. The poles 13 - also called stator teeth - each have a pole fork 15 of the branched type, which is provided with a fork groove 16 . The pole 13 is wound with at least two phase windings 17 , which optionally also surround the pole fork 15 . What is important here is that the pole 13 has at least one additional recess 18 on each pole branch 15 in order to form an additional pole branch 19 . In this way, the air gap 20 that exists between the outer peripheral surface of the stator 10 and the inner peripheral surface of the rotor 11 is partially widened, so as to achieve the corresponding function of the groove 14, more precisely, the function of the bifurcated groove 16 effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com