Veneer power-up device

A technology for electrical devices and single boards, which is applied to coupling devices, measuring devices, and components of connecting devices, etc., can solve problems such as power-on and power-off testing of single boards, power failure of single boards, and inconvenient disassembly and assembly. , to achieve the effect of stable and reliable working power, convenient installation and disassembly, and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

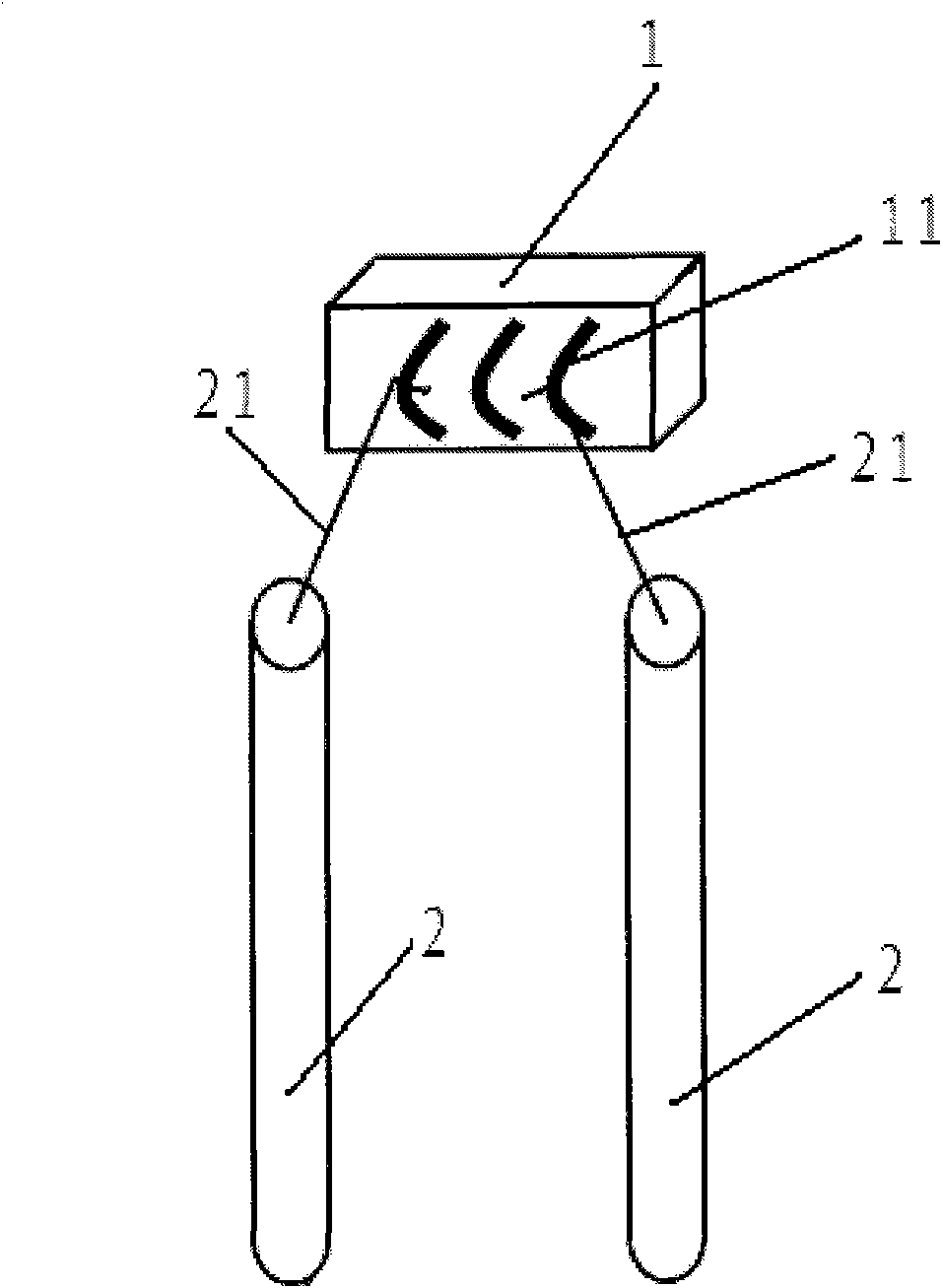

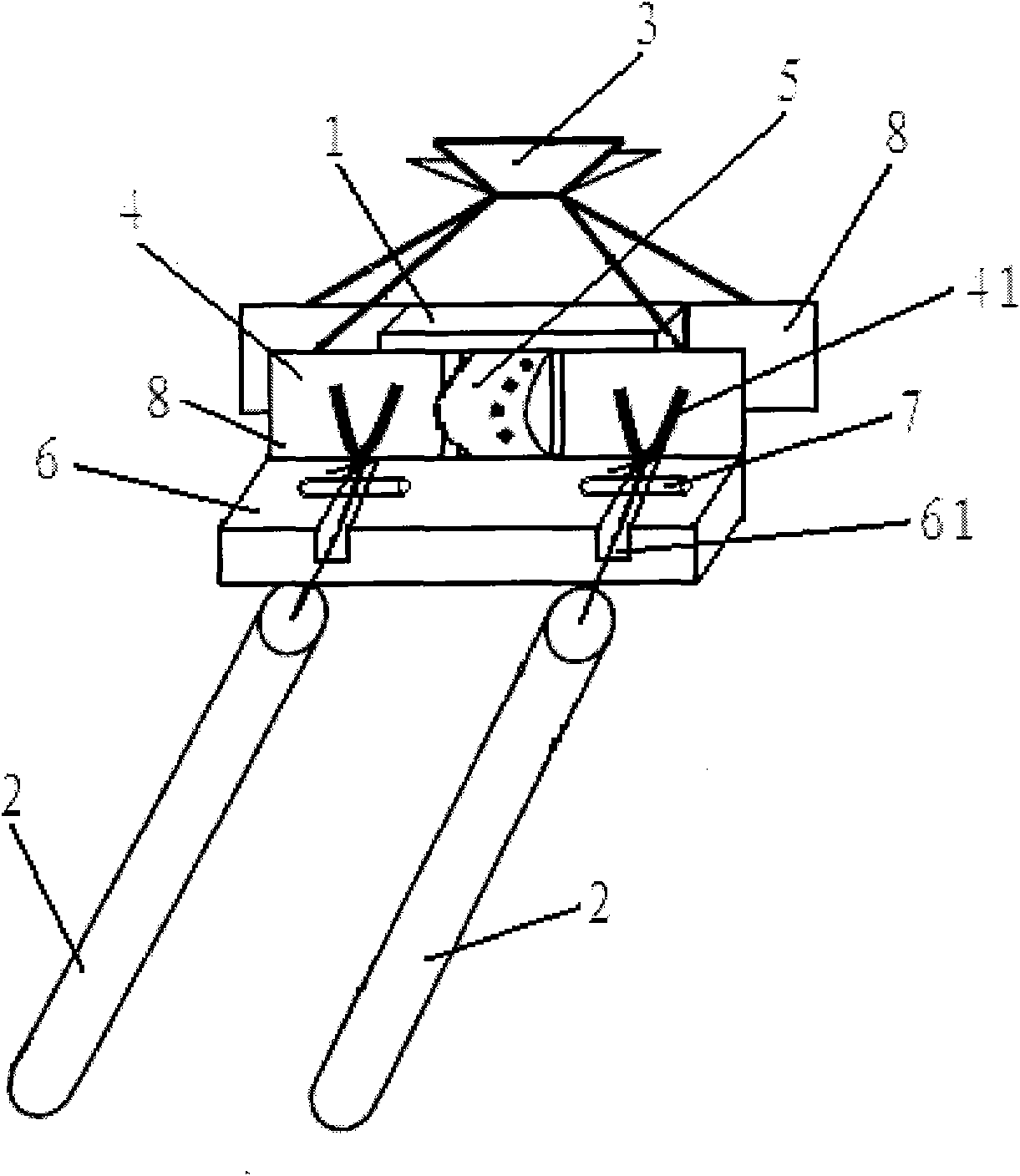

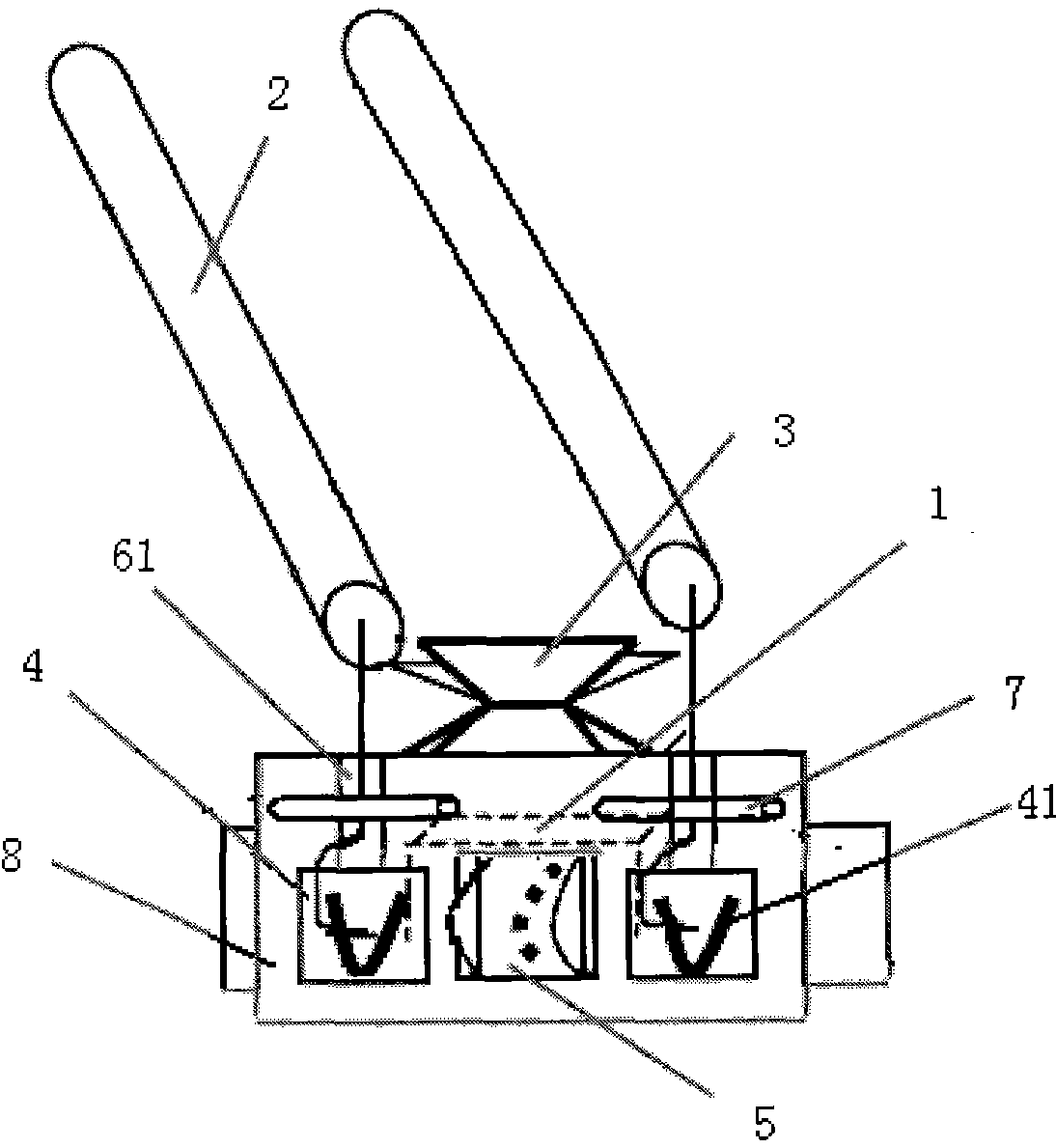

[0022] The basic idea of the present invention is that, by setting the power supply device of the single board as a clip structure, and setting the connecting piece and the conductive sheet on the clamp plate of the While working on the power supply, it is also convenient to disassemble the board. That is, as long as the two splints of the clip clamp the veneer, and then connect the charging rod with the hook and loop on the conductive sheet set on the splint, the veneer can be supplied with working power. Furthermore, by providing a groove for placing the hook telescopic wire and a small rod for holding the hook telescopic wire, the connection between the power rod and the power shrapnel of the single board is also relatively stable.

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail by citing the following embodiments and referring to the accompanying drawings. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com