Thyristor level test method for novel converter valve module

A converter valve module and thyristor-level technology, which is applied in the field of new converter valve module testing, can solve the problems of difficult implementation and complex test unit structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

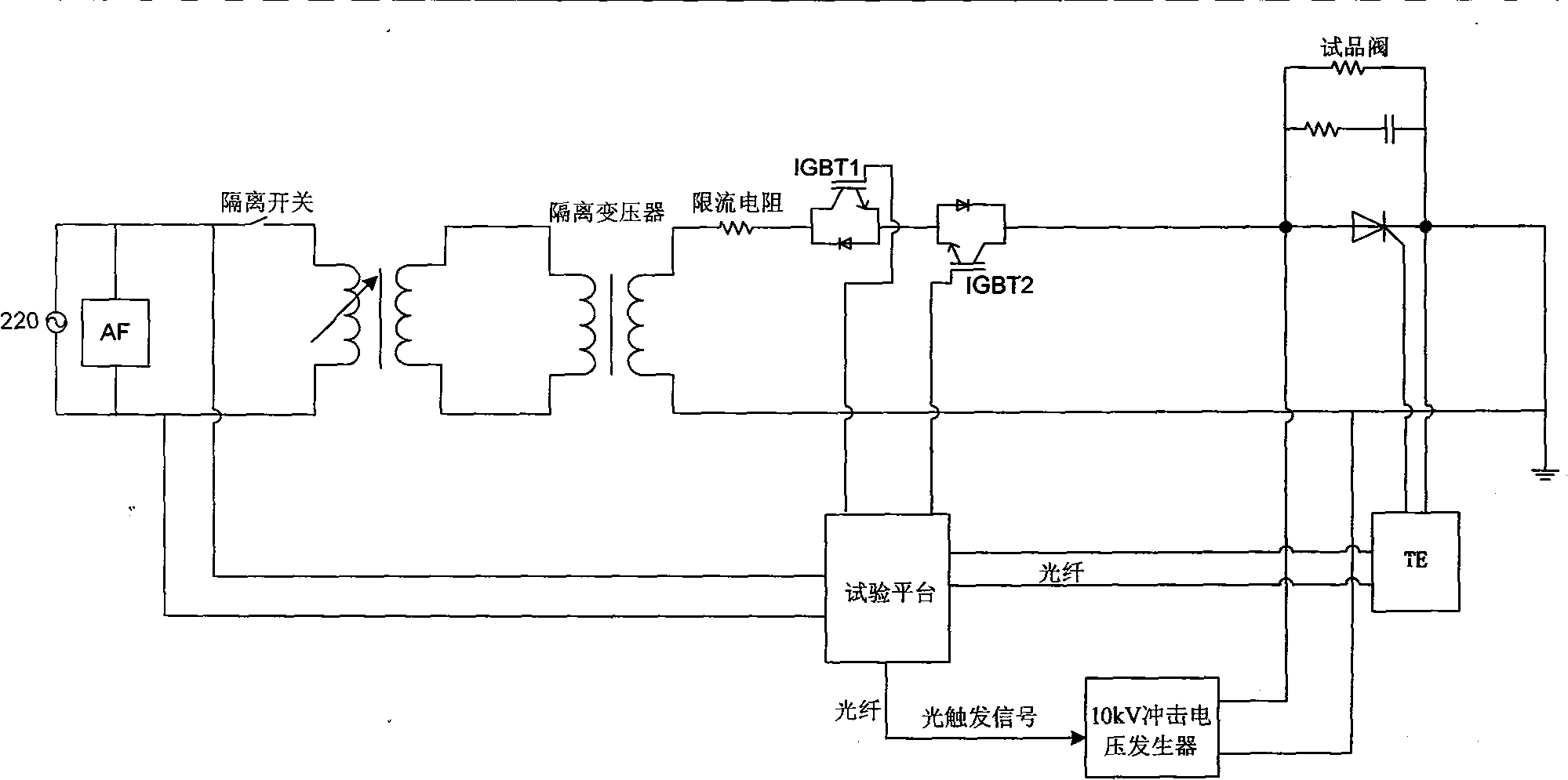

[0016] The technical scheme of the invention is attached figure 1 As shown, the test device is composed of a voltage regulator, an isolation transformer, a current limiting resistor, a TE test platform, an impulse voltage generator, a test object and TE. The 220Vms AC source and isolation transformer form a low-voltage circuit, and the impulse voltage generator forms a high-voltage circuit. The two complete the voltage waveform required by the functional test. TE test platform sends thyristor trigger coding pulse to TE, and receives status monitoring information reported by TE.

[0017] See attached figure 1 , The thyristor level test circuit of the converter valve module is composed of AC power supply, AC filter, isolation switch, voltage regulator, isolation transformer, current limiting resistor, forward and reverse series IGBT, impulse voltage generator, and test platform. In the circuit, the AC power supply is connected to the AC filter AF to obtain a better AC voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com