Coal mine underground remote control triangle protective shield

A shielding support and remote control technology, which is applied in the direction of mine roof support, mining equipment, earthwork drilling, etc., can solve problems such as hidden safety hazards, unsatisfactory support effect, and inability to adapt to rapid relocation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

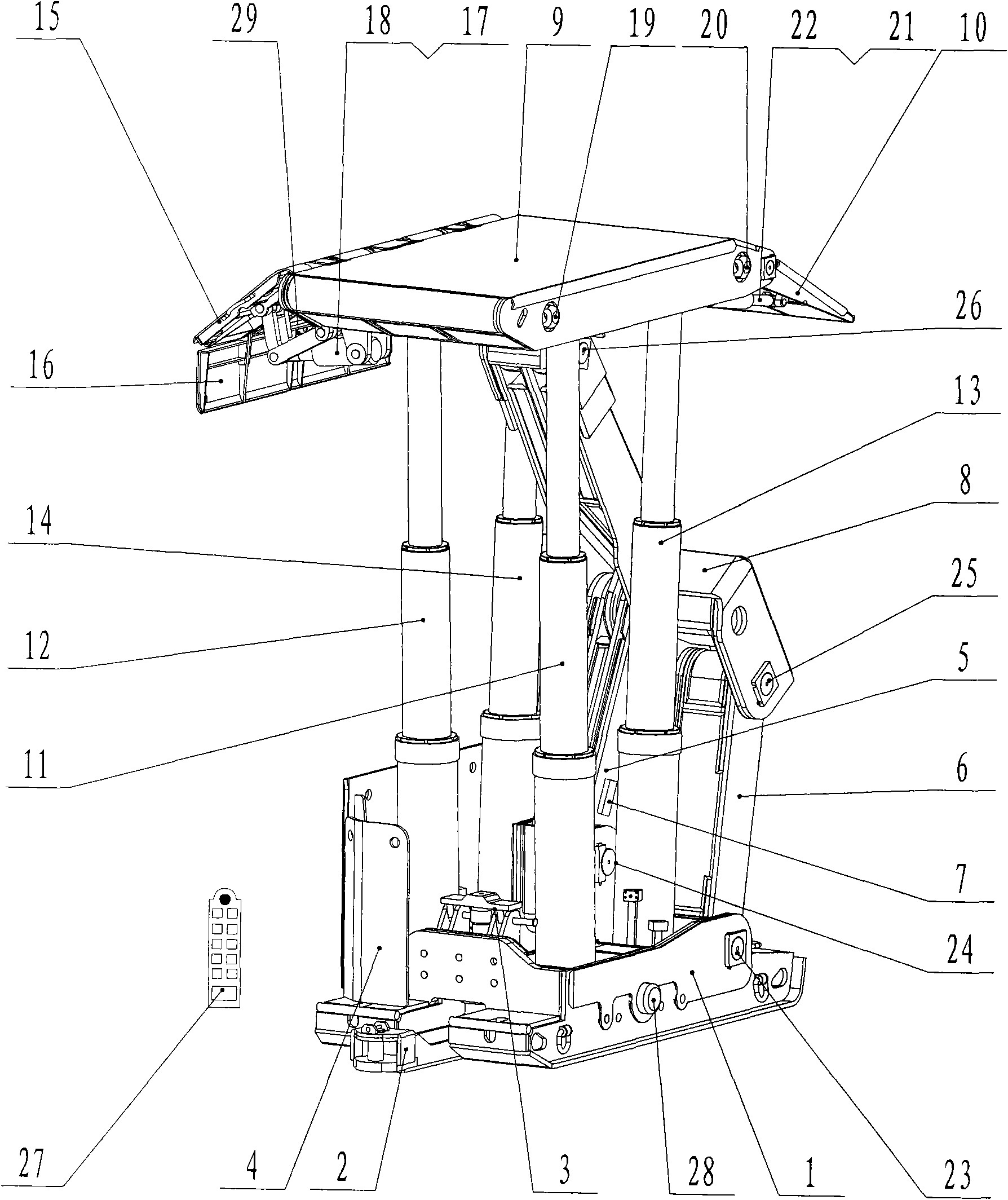

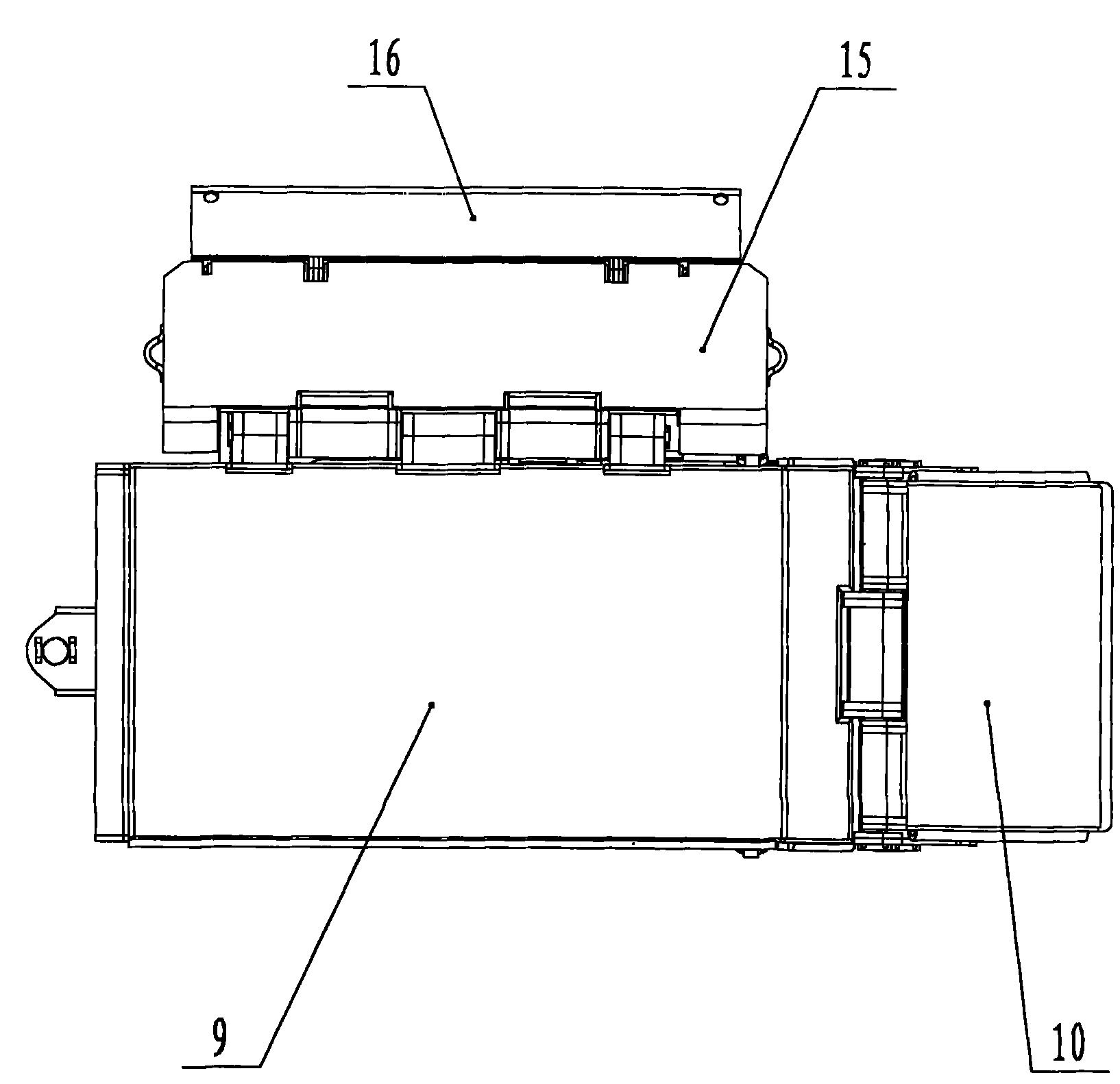

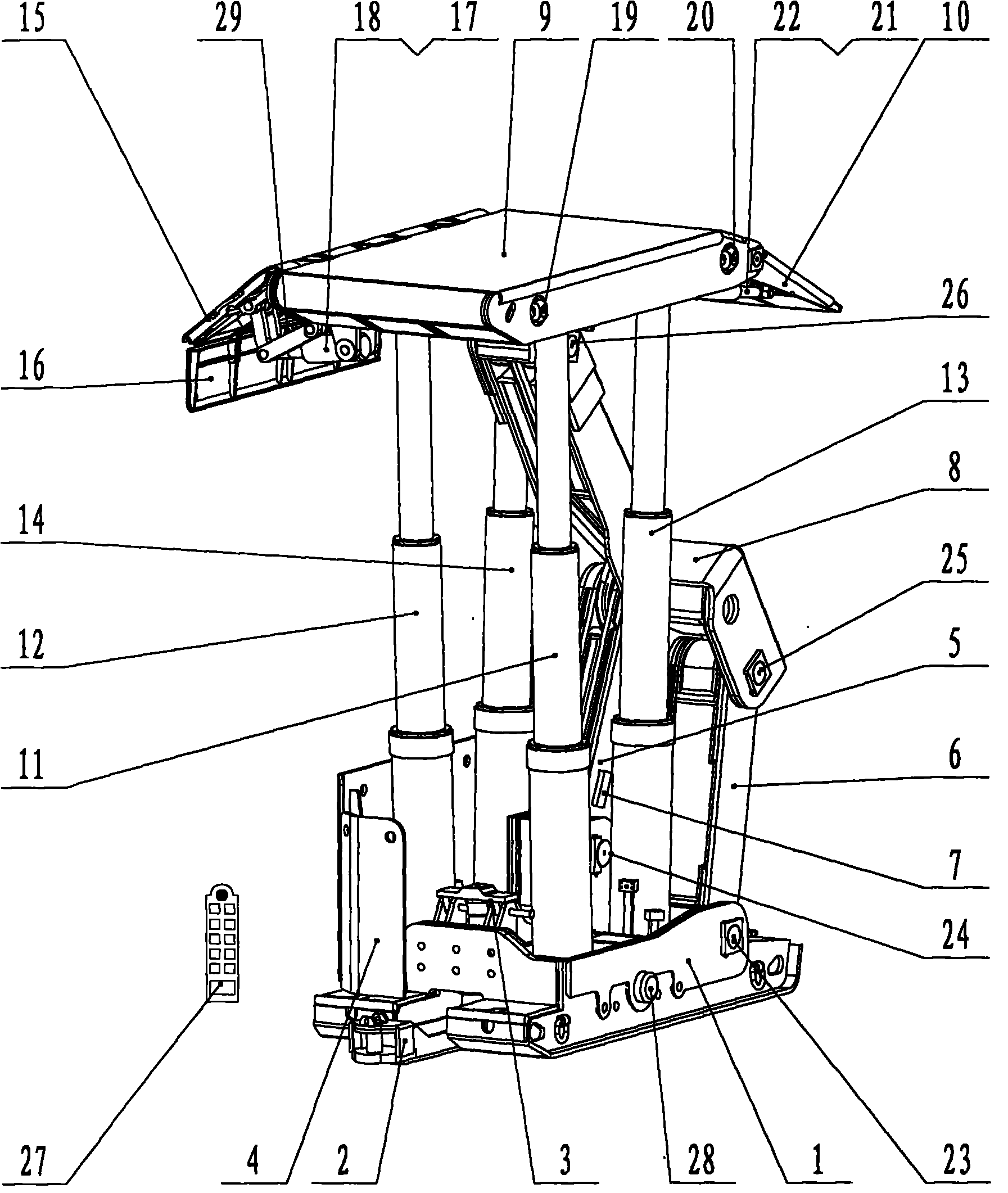

[0025] figure 1 Shown is the overall structure diagram, the position and connection relationship of each part must be correct, and the installation should be firm.

[0026] The front part of the base 1 is a push seat 2, the side of the base 1 is provided with a frame adjustment cylinder 28, the upper part of the middle position of the base 1 is provided with a hydraulic control mechanism 3, and the side part of the base 1 is provided with a guard plate 4;

[0027] The rear portion at the bottom 1 is provided with front connecting rod 5 and rear connecting rod 6, and is fixedly connected by first and second connecting shafts 23 and 24; The shield beam 8 is connected; the shield beam 8 is connected with the top beam 9 through the fourth connecting shaft 26;

[0028] The first, second, third and fourth column oil cylinders 11, 12, 13, 14 are symmetrically arranged on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com