Yarn-raising machine

A technology of yarn kicker and yarn board, which is applied in the direction of textiles and papermaking, and can solve problems such as time-consuming and labor-intensive work, high labor intensity of workers, and damage to the bobbin yarn surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

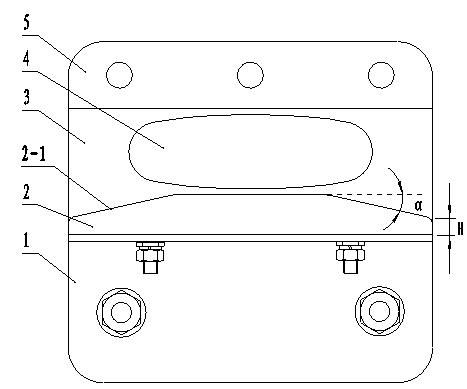

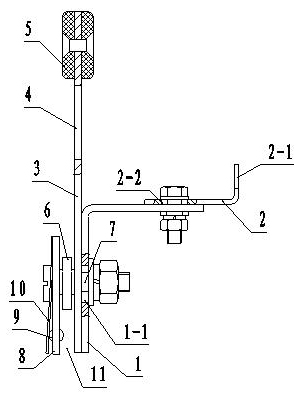

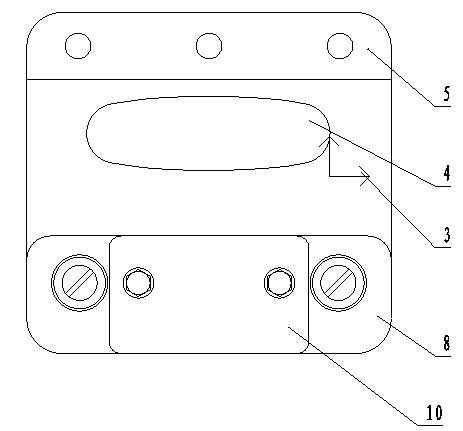

[0015] see figure 1 , figure 2 , The composition of the present invention includes a base plate 3 , a support plate 1 , a yarn raising plate 2 , a clamping plate 8 , a small shaft 7 and a bearing 6 . A handle 5 and a holding hole 4 are provided on the upper part of the base plate for holding operation. A support plate 1 is fixed on one side of the base plate, and a yarn raising board 2 is fixed on the top of the supporting board, and yarn raising slopes 2-1 are arranged on both sides of the edge of the yarn raising board; bearings 6 and clips are arranged in sequence on the other side of the supporting board A track groove 11 is formed between the plate 8, the clamping plate and the support plate. When the yarn lifting board is used to jack up the bobbin, it is placed on the track of the equipment so that the track is located in the track groove, the worker moves along the track with the yarn lifting device in hand, and the yarn lifting slope on the yarn lifting board penet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com