Biomass spiral pyrolytic process and antipyretic device

A technology of biomass and pyrolysis, which is applied in the direction of biofuel, petroleum industry, indirect heating dry distillation, etc., to meet the pyrolysis conditions, avoid heating, and increase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

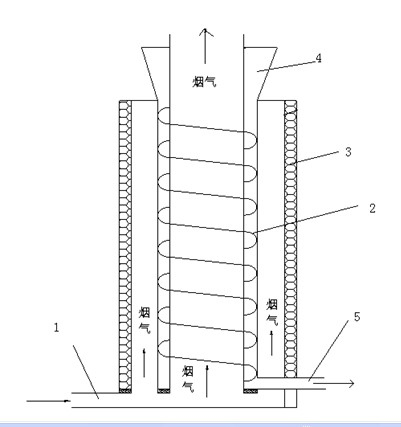

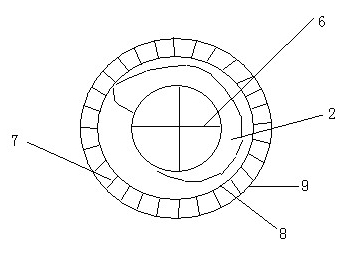

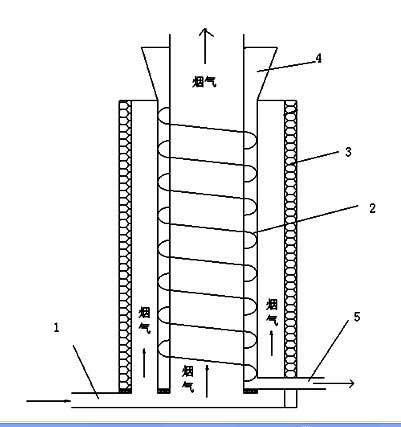

[0031] like figure 1 , 2 The shown pyrolysis device is composed of an outer cylinder, an inner cylinder and a screw propeller, and the screw propeller is placed in the inner cylinder; the screw propeller consists of a hollow cylinder rotating shaft that can rotate relative to the cylinder, and the The rotating shaft of the cylinder is fixed with a helical blade 2, and the extension end of the rotating shaft of the hollow cylinder is equipped with a frequency conversion motor; the upper and lower ends of the inner cylinder have a feed port 4 and a discharge port 5 respectively, and the outer cylinder and the inner cylinder The cylinders are all connected to the flue gas end, and the inner cylindrical channel is equipped with fins 6 perpendicular to each other to increase the heat exchange area, and the outer cylindrical flue gas channel is also installed with several fins 7 perpendicular to the axis. The outer cylinder is jacketed with insulating material to ensure maximum he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com