Adjusting and positioning mechanism for parts at high-speed milling center

A technology of high-speed milling and positioning mechanism, which is used in large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of repeated adjustment, loss of positioning effect, and decrease in stiffness of the joint surface, and achieves good positioning accuracy retention. , The position is easy to precisely control, and the effect of reducing the joint stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

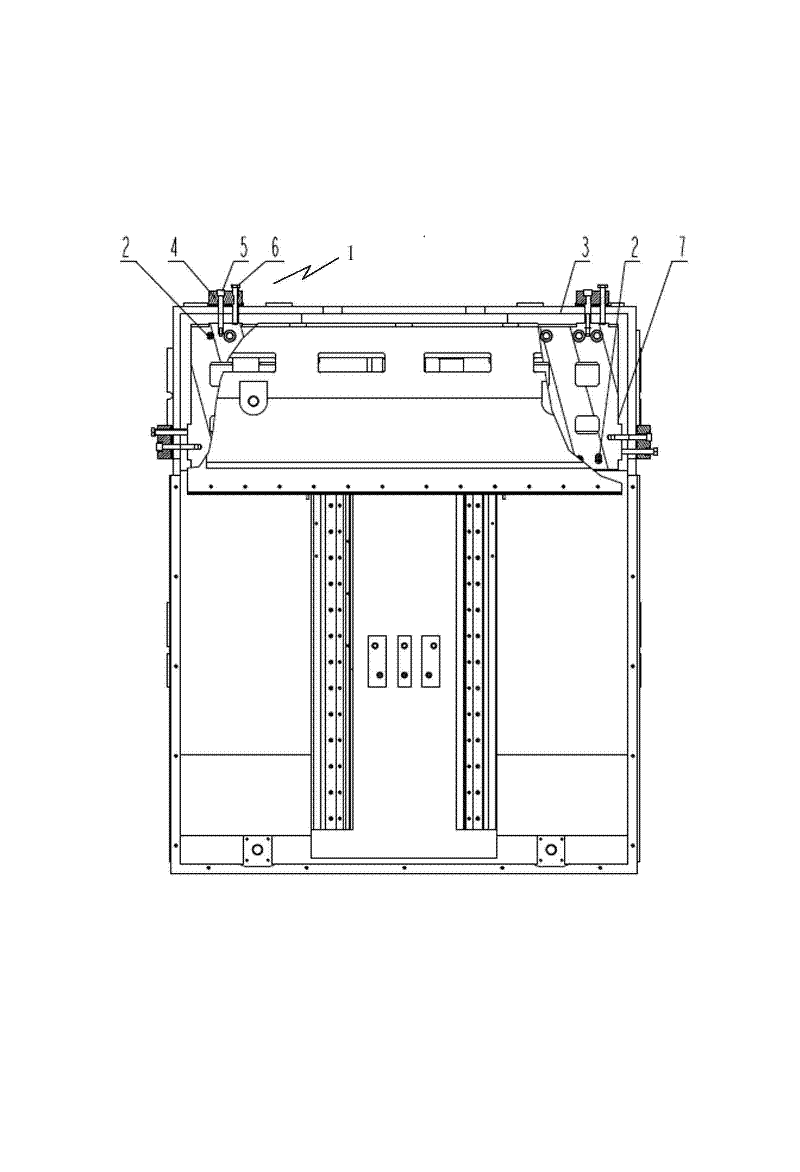

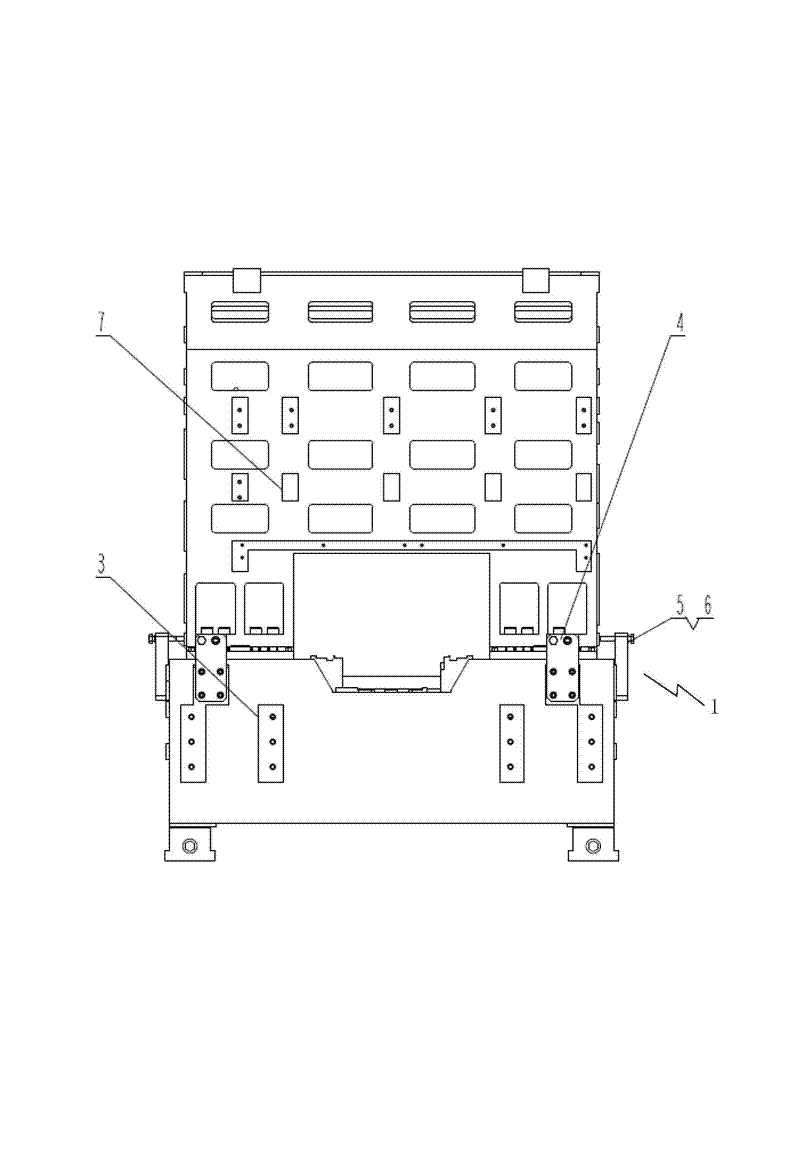

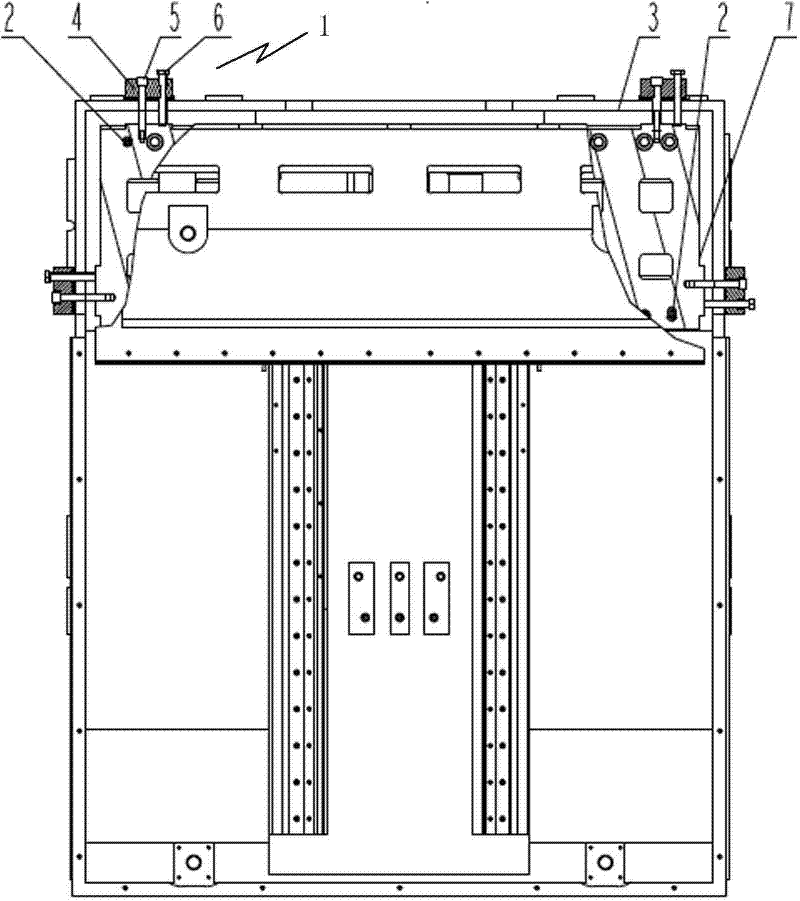

[0010] Such as figure 1 and 2 As shown, a high-speed milling center component adjustment and positioning mechanism is composed of four sets of screw mechanisms 1 and two positioning pins 2. The screw mechanism 1 is distributed on the side and rear of the base component 3 of the high-speed milling center. The positioning The pins 2 are distributed diagonally on the base part 1, and the positioning pins 2 are connected with the adjustment part 7 of the high-speed milling center, and the positioning pins 2 can be internal threaded conical pins.

[0011] The screw mechanism 1 includes an adjustment bracket 4, a hexagon socket head cap screw 5 and a fully threaded hexagon head bolt 6, wherein the adjustment bracket 4 is connected to the base part 3, and the hexagon socket head cap screw 5 is connected to the adjustment part 7 through the adjustment bracket 4, The full-threaded hex head bolt 6 is flexibly connected with the adjustment bracket 4.

[0012] The movement principle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com