Vent design method for casting die

A design method and casting mold technology, applied in the field of mold manufacturing, can solve problems such as difficult exhaust, achieve the effects of eliminating residual gas, ensuring integrity, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A venting design method for a casting mold comprises the following steps in sequence.

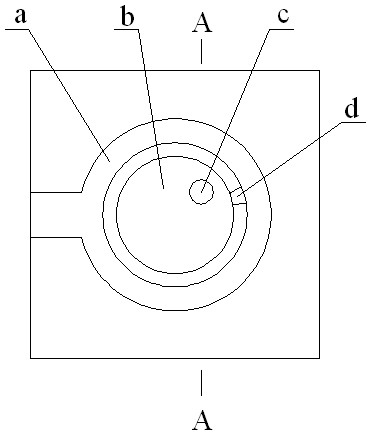

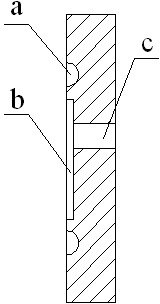

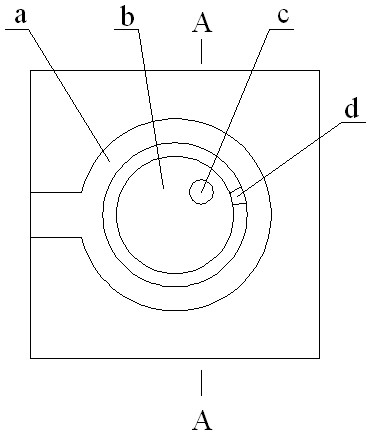

[0016] (1) Process a 2mm deep pit b at the part surrounded by the surrounding or semi-surrounding cavity a, and the edge of the pit b is 7mm away from the edge of the cavity a.

[0017] (2) Process the vent hole c at a position that does not interfere with other components of the mold within the range of the pit b.

[0018] (3) When testing the mold, a 0.1mm deep exhaust groove d is processed at the place where the gas stays in the mold cavity a, and the two ends of the exhaust groove d are respectively connected with the mold cavity a and the pit b.

Embodiment 2

[0020] A venting design method for a casting mold comprises the following steps in sequence.

[0021] (1) Process a 3mm deep pit b at the part surrounded by the surrounding or semi-surrounding cavity a, and the edge of the pit b is 9mm away from the edge of the cavity a.

[0022] (2) Process the vent hole c at a position that does not interfere with other components of the mold within the range of the pit b.

[0023] (3) When testing the mold, process a 0.13mm deep exhaust groove d at the place where the gas stays in the mold cavity a, and the two ends of the exhaust groove d are respectively connected with the mold cavity a and the pit b.

Embodiment 3

[0025] A venting design method for a casting mold comprises the following steps in sequence.

[0026] (1) Process a 5mm deep pit b at the part surrounded by the surrounding or semi-surrounding cavity a, and the edge of the pit b is 10mm away from the edge of the cavity a.

[0027] (2) Process the vent hole c at a position that does not interfere with other components of the mold within the range of the pit b.

[0028] (3) When testing the mold, a 0.15mm deep exhaust groove d is processed at the place where the gas stays in the cavity a, and the two ends of the exhaust groove d are respectively connected to the cavity a and the pit b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com