Non-spherical lens rigid endoscope

A technology of aspheric lens and endoscope, which is applied in the field of aspheric lens group rigid tube endoscope, can solve the problems of increased financial burden, image blurring, and disappearance of patients, and achieve good operation effect, reduce use cost, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

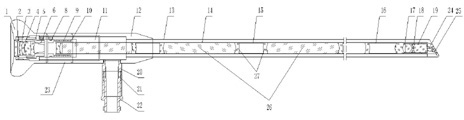

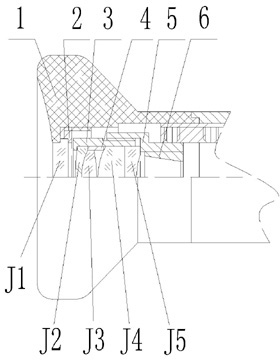

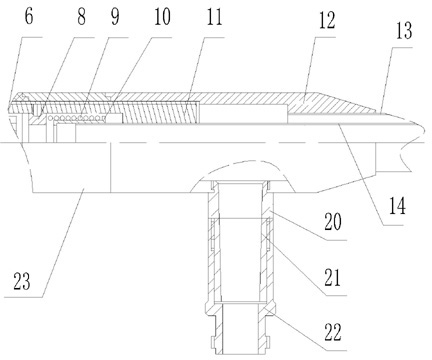

[0023] see Figure 1 to Figure 8 The eyepiece system of the aspherical lens group rigid tube endoscope in the embodiment of the present invention uses the eyepiece cover 1 as the base, and the protective sheet pressure ring 2 is connected with the screw thread matching the eyepiece cover 1 to press and fix the eye end protective sheet J1. The inner cavity of the eyepiece cover 1 is provided with a first eyepiece tube 3 and a second eyepiece tube 5, and the first eyepiece tube 3 and the second eyepiece tube 5 are connected by a screw pair to fix two groups of aspheric lenses. The first aspheric lens group is composed of aspheric lenses. Spherical lens one J2 and aspheric lens two J3 are glued together, the second aspheric lens group is made of aspheric lens three J4 and aspheric lens four J5 glued together, the first aspheric lens group and the second aspheric lens group are set An eyepiece spacer 4 is provided to ensure the installation positions of two groups of aspheric lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com