Method and device for the detection of defects in an object

A technology for objects and defects, applied in the field of devices implementing the method, can solve the problems of hindering defect detection, unreliability, etc., and achieve the effect of avoiding detection of direct transmitted light and primary reflected light, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

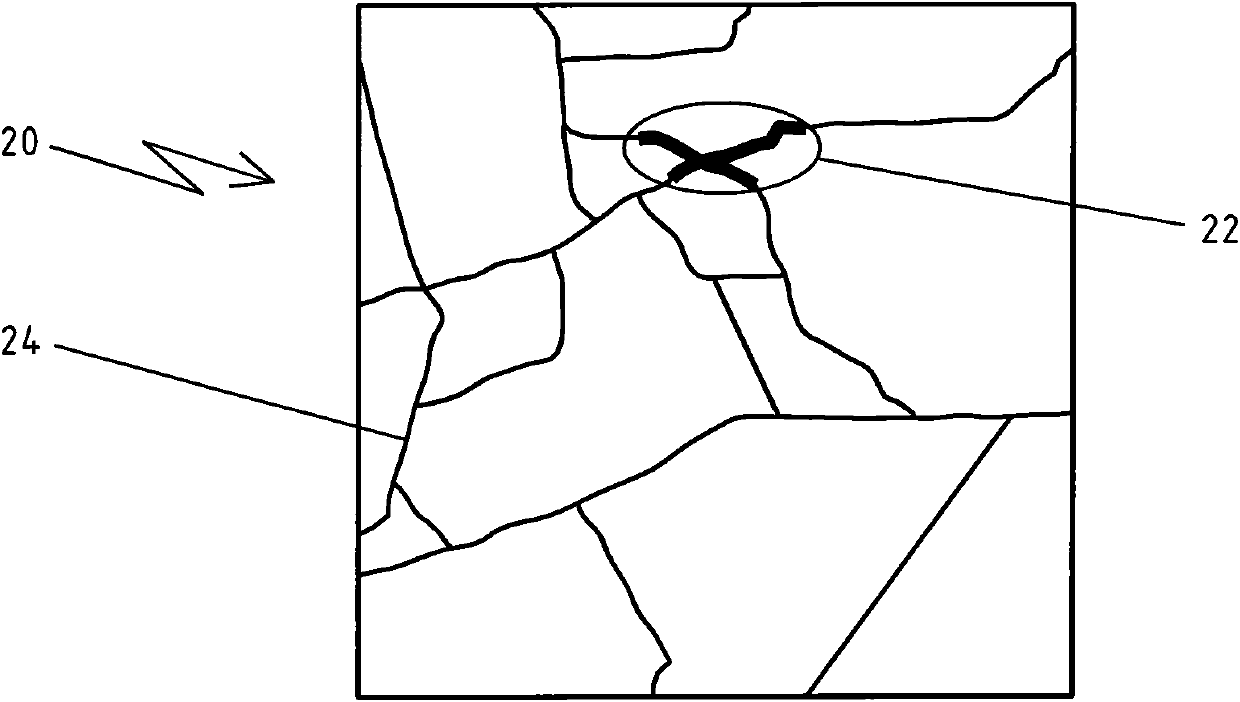

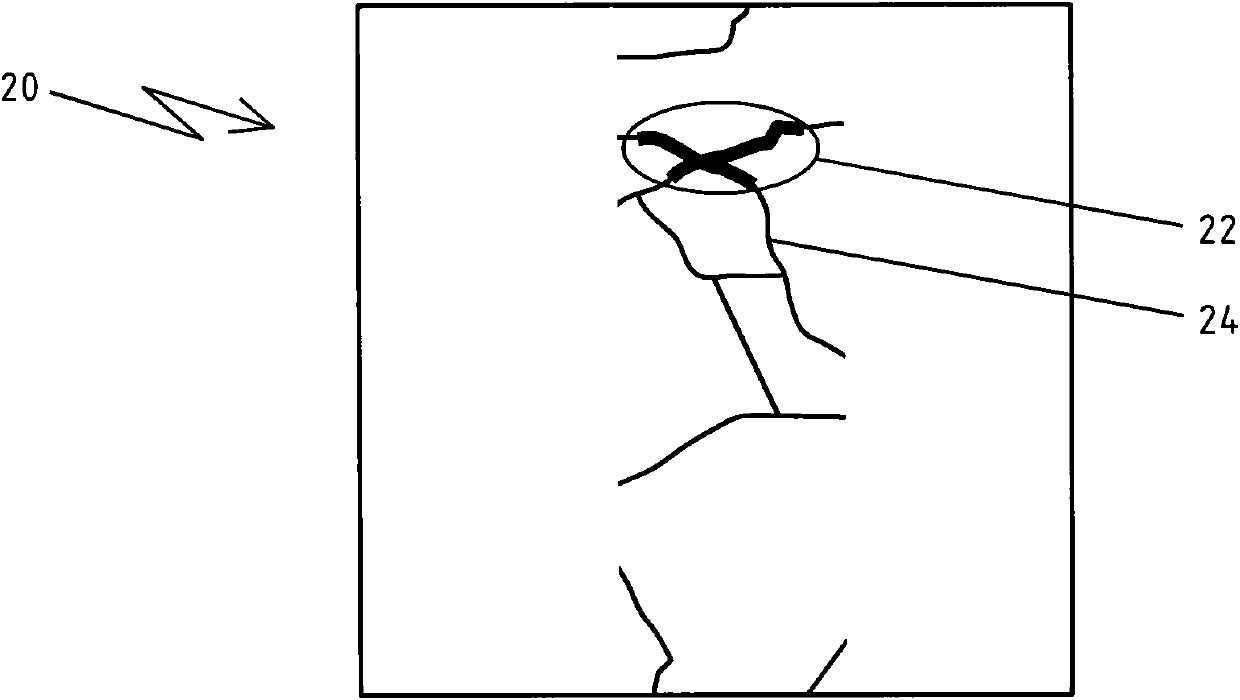

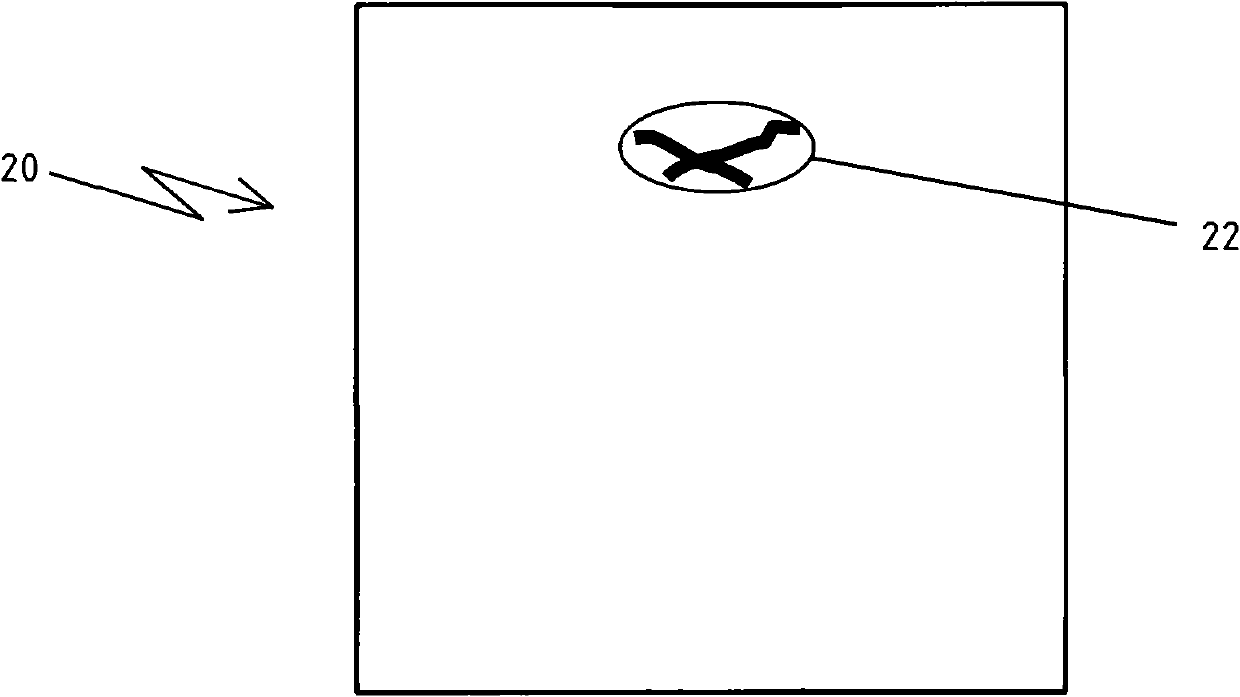

[0050] Figure 4 A first embodiment of the method according to the invention is shown in conjunction with a schematic diagram. According to this first embodiment, the polysilicon body is locally irradiated with infrared light (step 10). Furthermore, the light is detected (step 12) in a detection region which is spaced apart from an irradiation region in which the silicon body is locally irradiated and an exit region in which the silicon body is locally irradiated in order to locally irradiate The infrared light incident on the body is directly transmitted from the exit area. In this way, the detection of the direct transmission of the incident infrared light or the detection of the primary reflection of the infrared light can be largely avoided. As mentioned above, residual defects, in particular cracks or inclusions, can be identified using characteristic intensity differences in the detected portion of the incident light. Thus, analyzing this intensity difference, and in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com