Arranging structure of heaters on bearing-steel isothermal spheroidized annealing furnace

A technology of isothermal spheroidization and layout structure, which is applied in the field of heater layout structure on the warm spheroidization annealing furnace, can solve the problems of polluting the environment, wasting heat energy, wasting heat energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

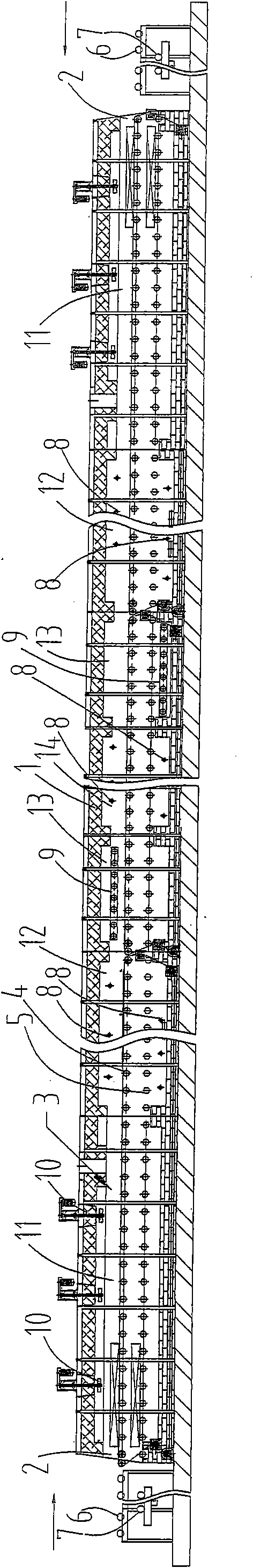

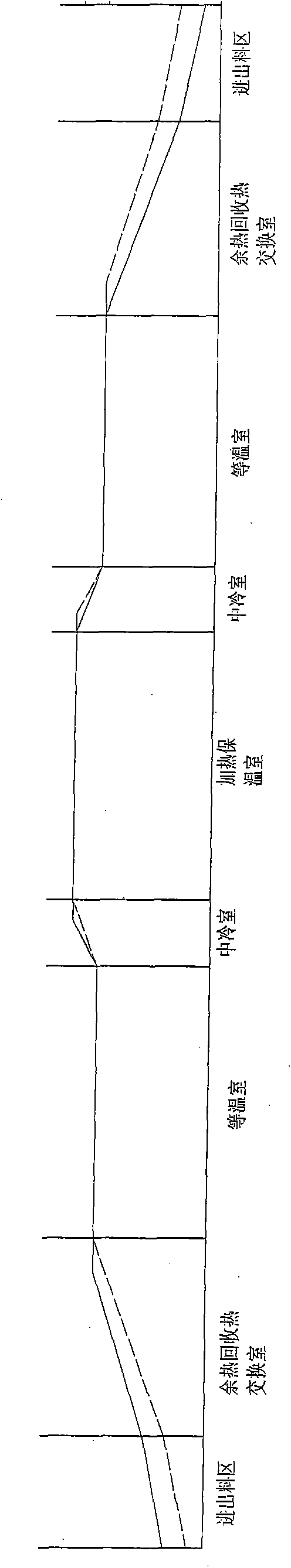

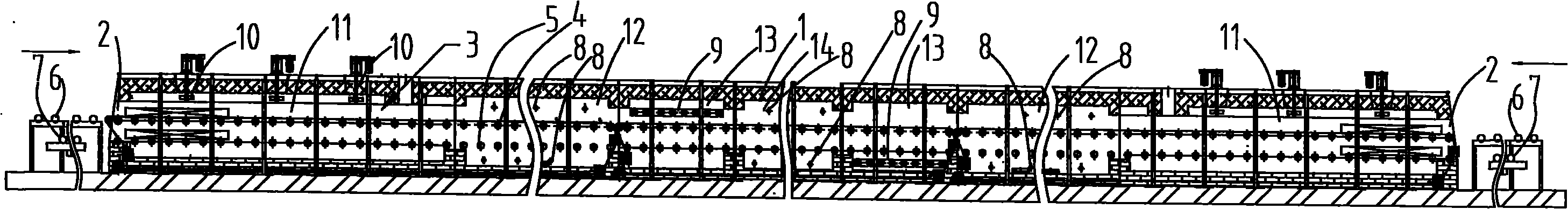

[0012] see figure 1 As shown, the bearing steel isothermal spheroidizing annealing furnace includes a furnace body 1 with a furnace mouth 2 at the front and rear ends, and the furnace body 1 has a furnace 3 connected with the furnace mouth 2 at the front and rear ends. The furnace port 2 enters the furnace chamber 3, and after annealing treatment, it is output from the furnace port 2 at the other end. figure 1 In the above, the left side of the observer is defined as the front, and the right side is defined as the rear, and the upper and lower two-layer drive roller sets 4 and 5 for horizontally conveying the bearing steel between the furnace mouths 2 at the front and rear ends are arranged in the furnace 3, The upper and lower material roller tables 6 and 7 are arranged in front of the furnace mouth 2 at the front end of the furnace body 1 and behind the furnace mout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com