Iron tower climbing articulated robot

A technology of robots and iron towers, applied in the field of robots, can solve problems such as affecting work efficiency, insecurity, and consuming the physical strength of maintenance personnel, and achieve the effect of high labor intensity and strong ability to overcome obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention is given below in conjunction with the accompanying drawings, and the present invention will be further described through the embodiment. It should be pointed out that the specific implementation of the present invention is not limited to the forms described in the examples.

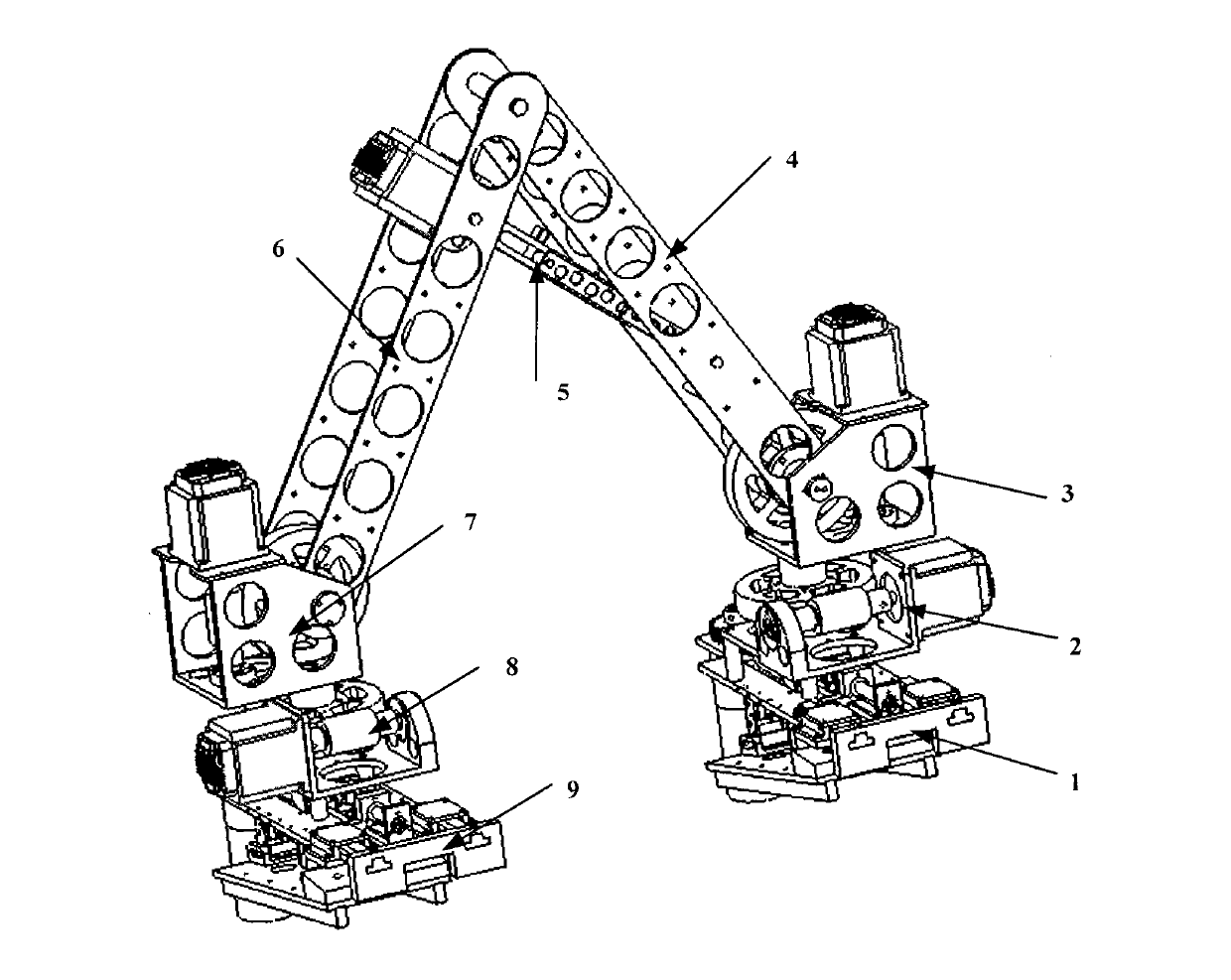

[0020] The articulated iron tower climbing robot provided by the present invention has an overall structure diagram as attached figure 1 As shown, it includes a pair of mechanical arms 4 and 6, an electric cylinder 5 that drives the opening and closing of the mechanical arms, and a mechanical arm. Joint 2 is used to connect the lower end of the arm with pitch joints 3 and 7 of the manipulator.

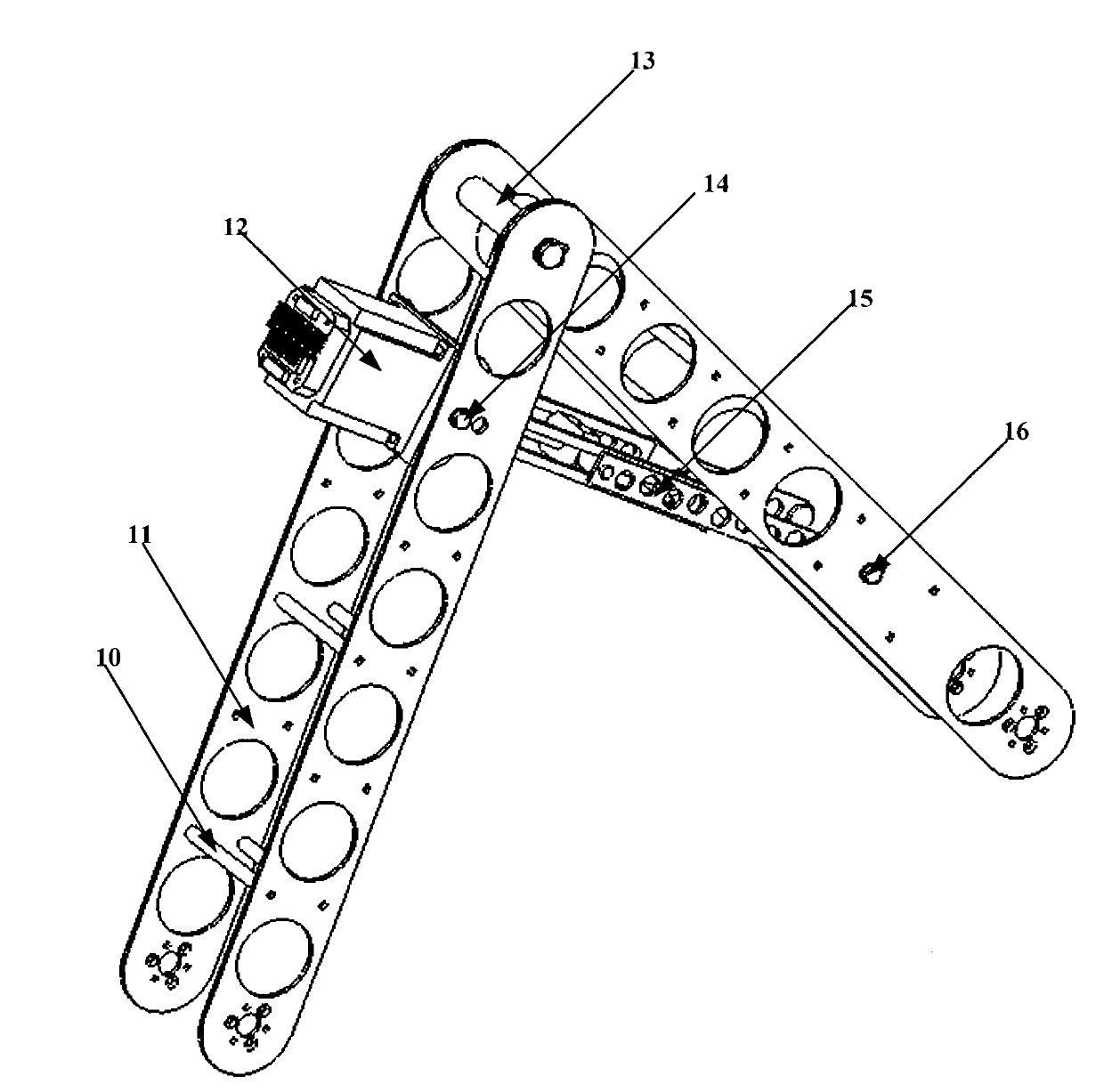

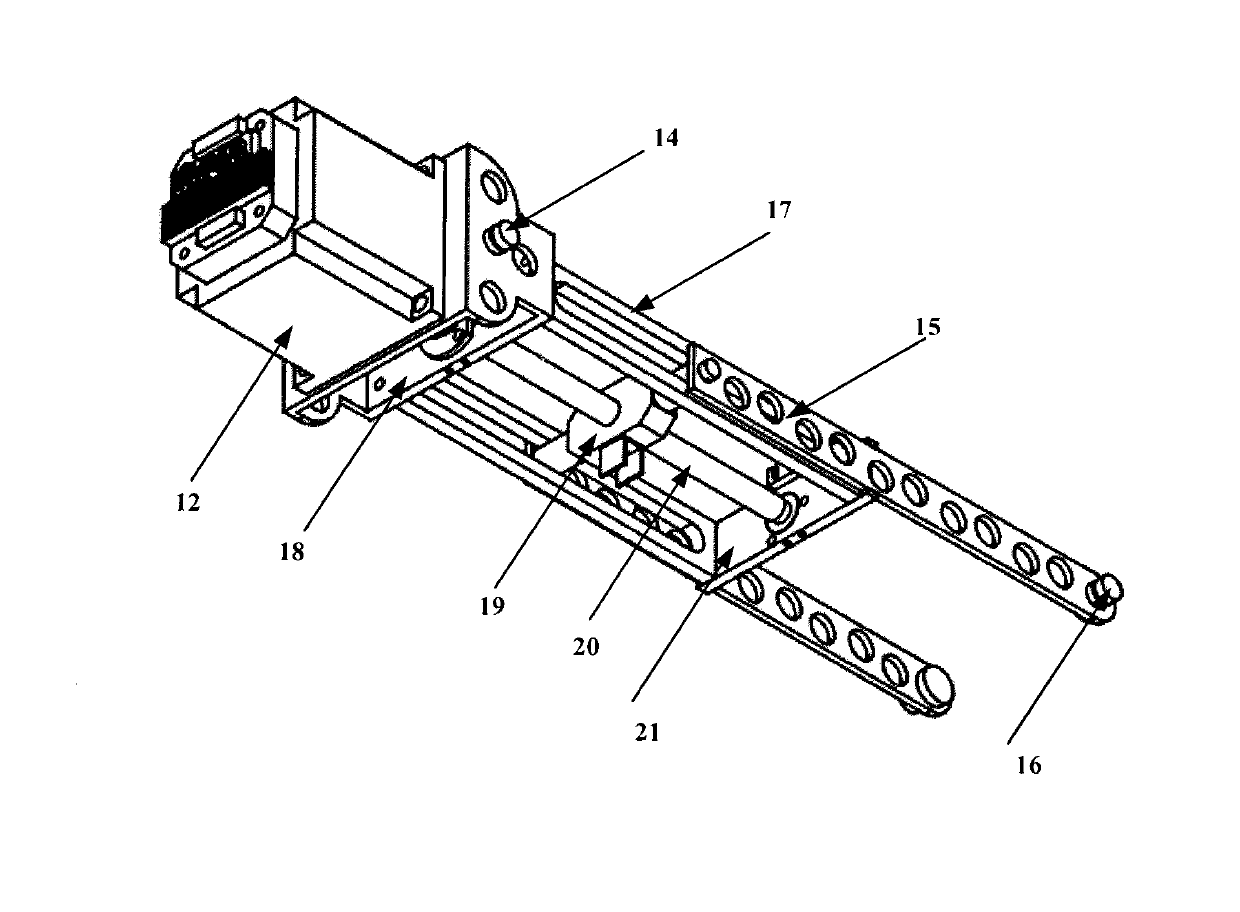

[0021] attached figure 2 and 3 It is the implementation structure of the robot arm and the electric cylinder. The mechanical arm is composed of a thin plate 11 and a supporting pin 10, which has a simple structure and good rigidity; the electric cylinder is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com