Bearing device

一种轴承装置、轴向的技术,应用在轴承、轴承元件、轴和轴承等方向,能够解决嵌合力不均匀、密封力不均匀、降低防尘圈成形、加工的作业性等问题,达到制造成本降低、提高密封性能、实现生产效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

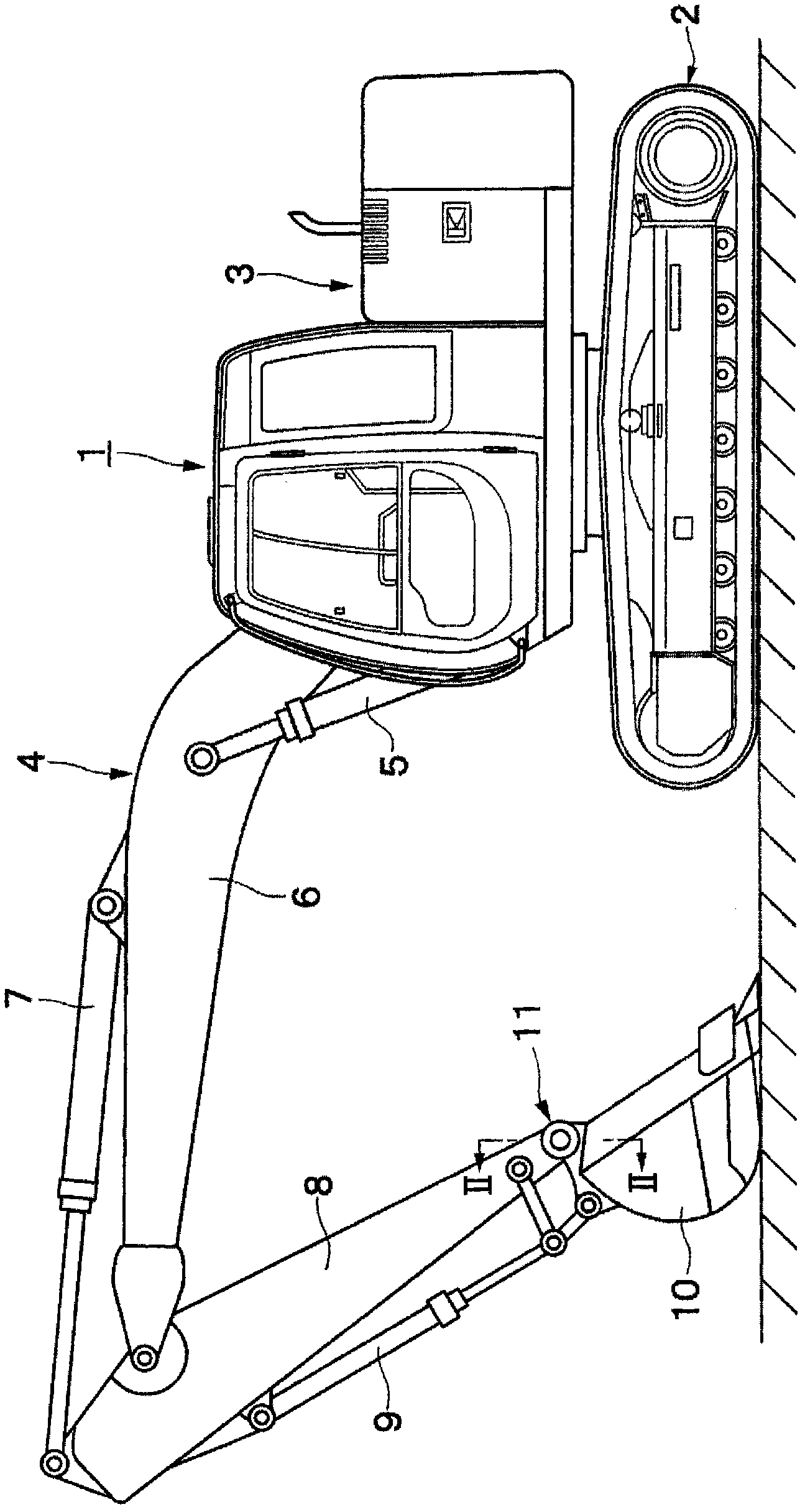

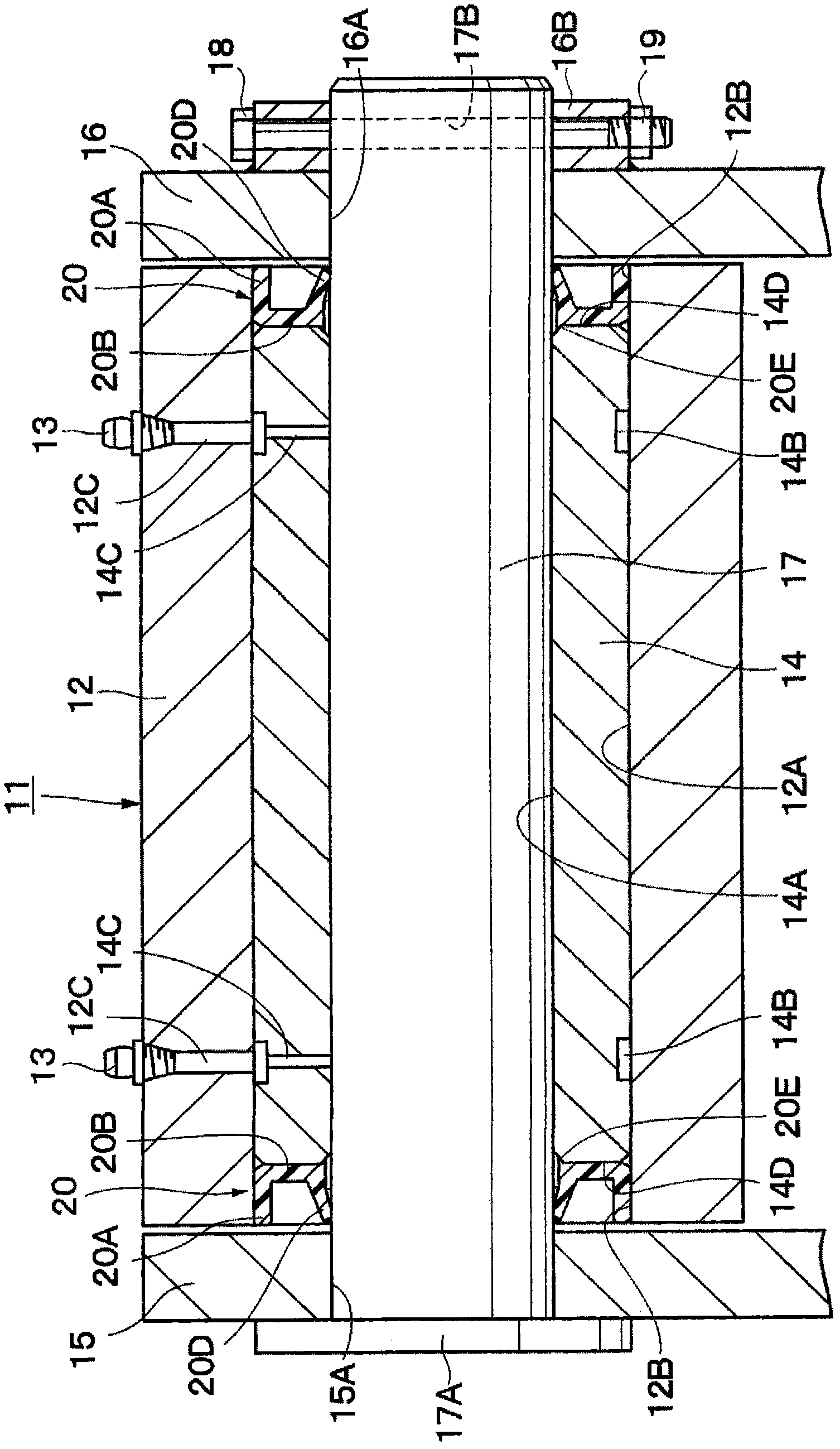

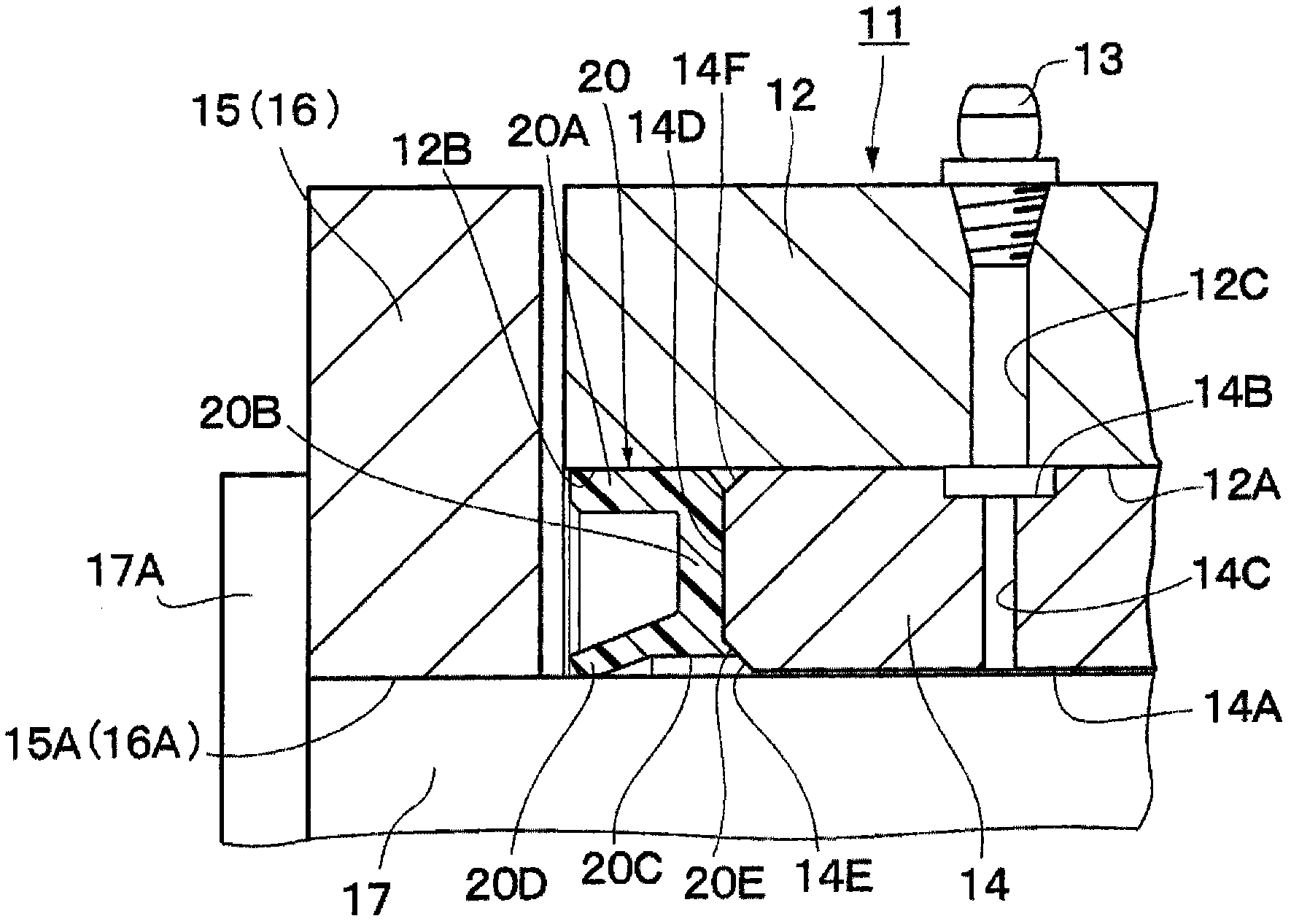

[0032] Hereinafter, a case in which the bearing device according to the embodiment of the present invention is used as an example in a connecting portion between an arm and a bucket of a work implement installed in a hydraulic excavator will be described in detail with reference to the drawings.

[0033] first, Figure 1 to Figure 9 A bearing device according to a first embodiment of the present invention is shown. In the figure, reference numeral 1 is a hydraulic excavator as a construction machine, and the hydraulic excavator 1 generally includes: for example, a crawler-type lower traveling body 2; an upper revolving body 3 that can be swivelly installed on the lower traveling body 2; And the working device 4 provided on the front side of the upper revolving structure 3 so as to be capable of pitching motion. In this case, the lower traveling body 2 and the upper revolving body 3 constitute the vehicle body of the hydraulic excavator 1 .

[0034]Furthermore, the working de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com