Conveying structure for movable storage rack

A technology for racks and chain conveyors, applied in the field of racks, can solve the problems of poor speed control, easy to produce impact, and the roller line can not be too long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

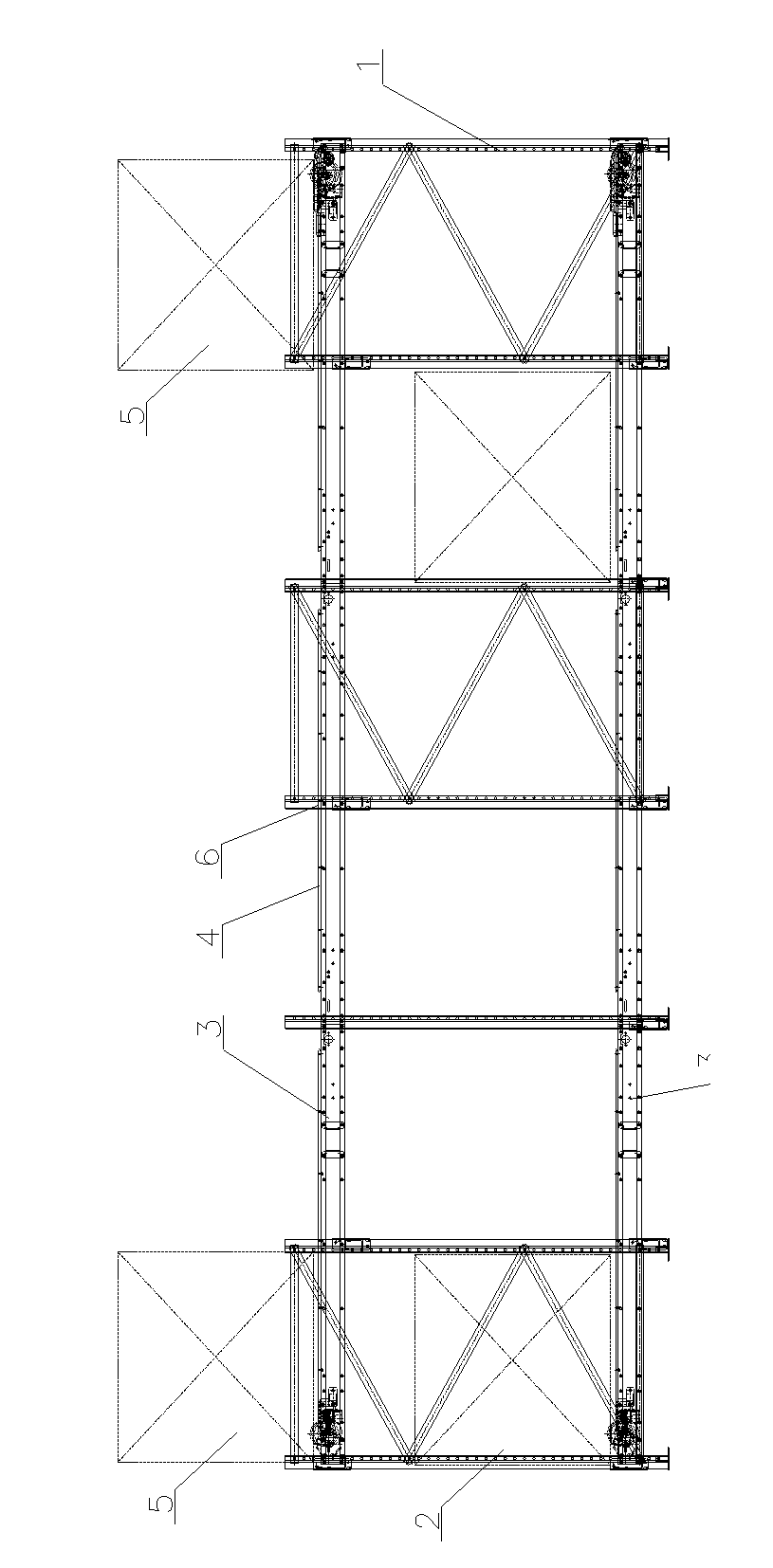

[0009] See figure 1 , figure 2 , which includes a delivery end 1 and a delivery end 2, the delivery end 1 and the delivery end 2 are connected by a track, the track is a horizontal track, and the horizontal track is specifically a chain conveyor 3, and a chain 4 is installed on the chain conveyor 3 , the cargo 5 is supported on the upper end surface of the chain 4, and the intermediate position of the chain conveyor 3 is supported on the intermediate shelf 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com