Rudderless course control device for ship

A technology for manipulating devices and ships, which is applied in ship propulsion, ship parts, ship construction, etc., and can solve problems such as increasing the forward resistance of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

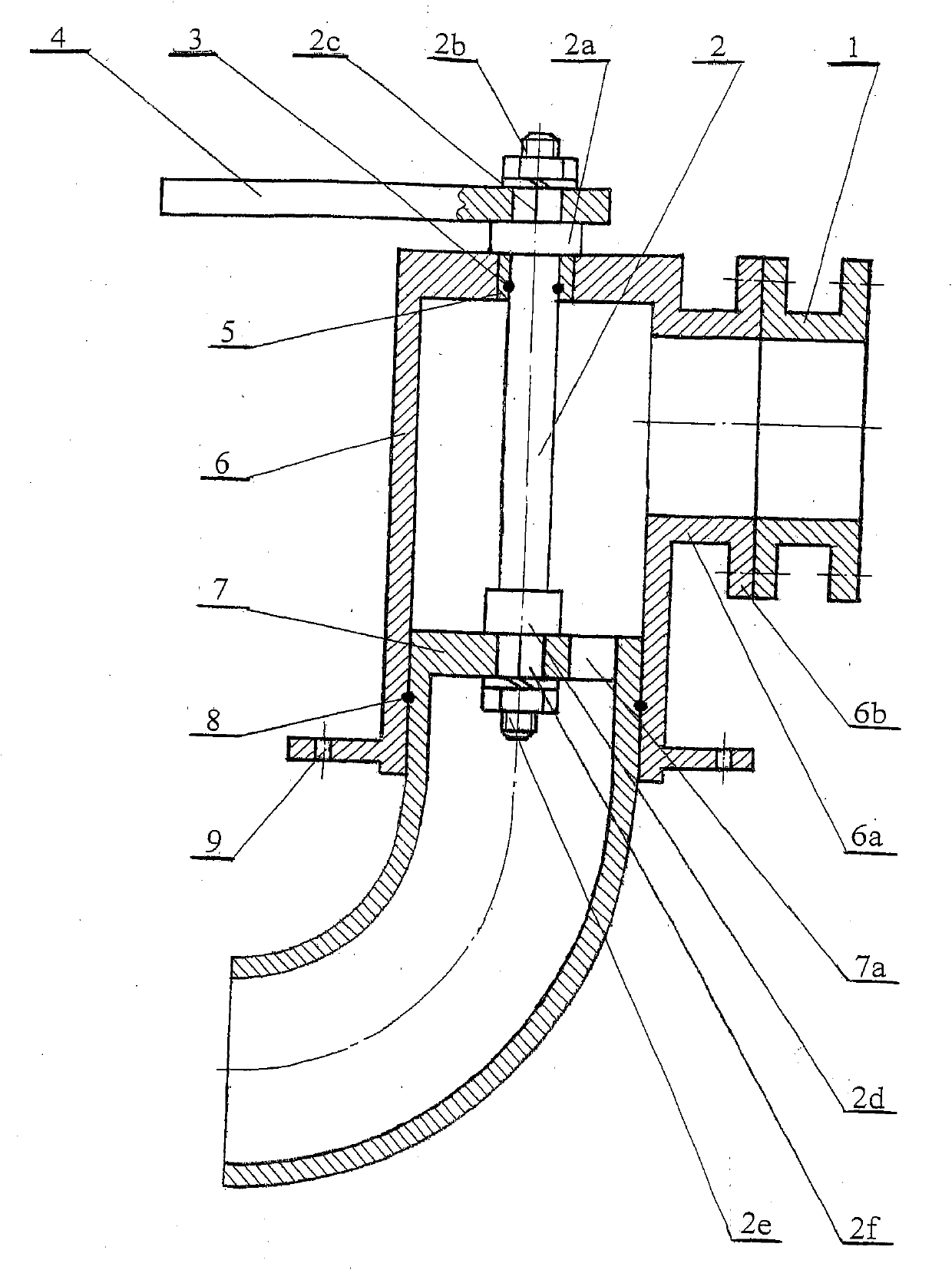

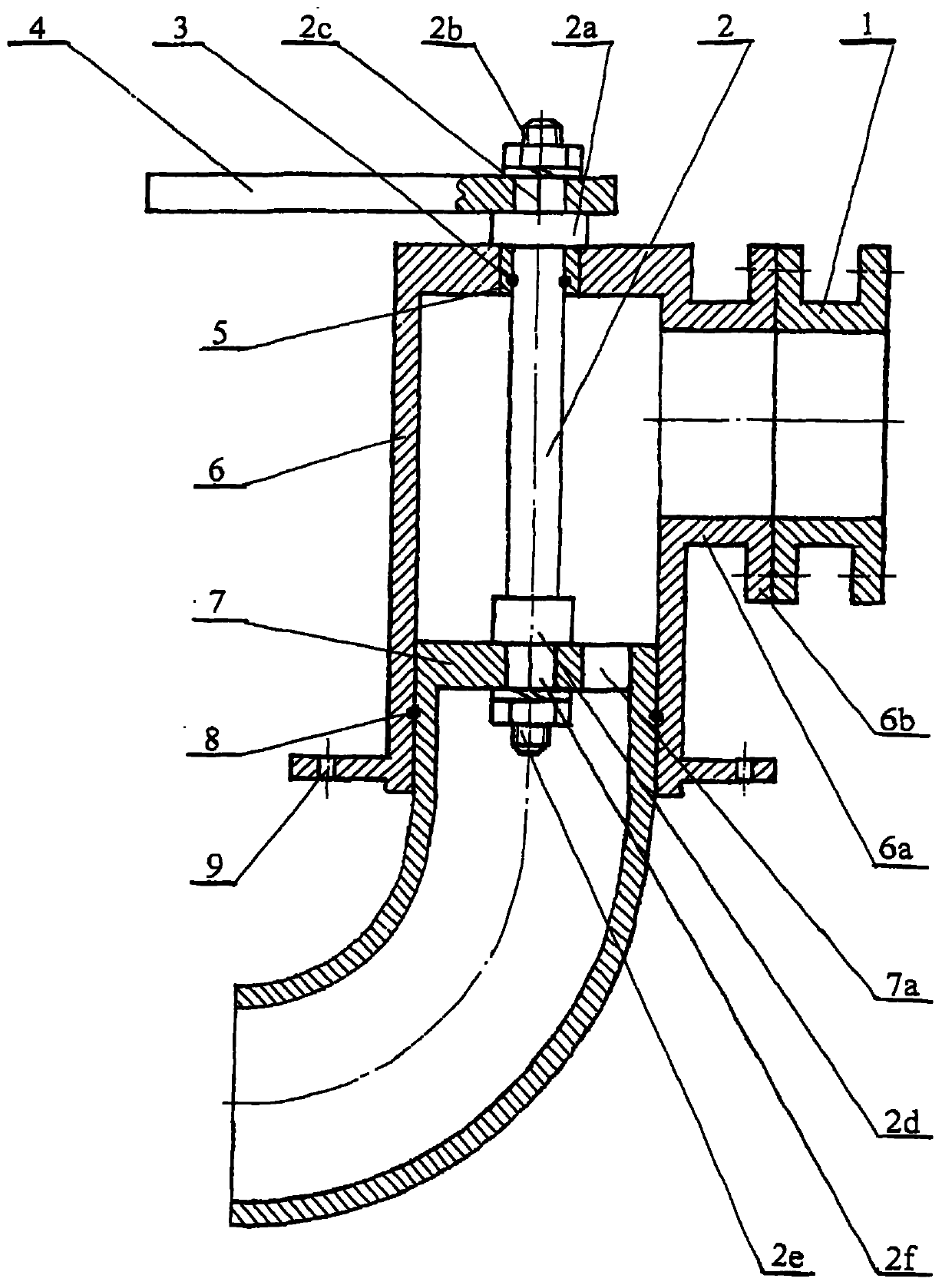

[0008] Example 1 is shown in the drawings. A hollow cylindrical body 6 with a top and no bottom, a circular through hole in the center of the top cover, a sliding bearing 5 is embedded in the through hole, and an upright joystick 2 is inserted into the circle through the sliding bearing 5 In the inner cavity of the cylinder 6, at the top of the joystick 2 exposed outside the top cover of the cylinder 6 is an upper threaded section 2b, below the upper threaded section 2b is a section of upper tenon section 2c, and under the upper tenon section 2c is a ring The upper shoulder blade 2a is pressed on the top surface of the cylinder 6 to position the joystick 2 up and down. A horizontally placed joystick 4 has a square tenon hole that matches the upper tenon section 2c, and the joystick 4 is placed on the upper tenon. The segment 2c is fixed with a nut screwed on the upper threaded segment 2b, and the operating handle 4 and the operating rod 2 are connected as a whole.

[0009] The b...

Embodiment 2

[0012] Embodiment 2 is shown in the figure. A rubber control rod sealing ring 3 is embedded in the contact part of the sliding bearing 5 and the joystick 2. That is, there is a ring of grooves (or both There are grooves on the corresponding parts), and the joystick sealing ring 3 is embedded in the groove. The operating rod sealing ring 3 is used to prevent the water entering the inner cavity of the cylindrical body 6 from leaking out of the cylindrical body 6 along the operating rod 2. Of course, the number of the joystick sealing ring 3 can be two or three, and the sealing effect is better. Others are the same as Embodiment 1, and will not be described again.

Embodiment 3

[0013] Example 3 As shown in the figure, a rubber-made right-angle elbow sealing ring 8 is embedded on the contact part of the right-angle elbow 7 and the cylindrical body 6, that is, the right-angle elbow 7 or the cylindrical body 6 in this part There is a ring of grooves (or both corresponding parts have grooves), and the right-angle elbow water sealing ring 8 is embedded in the groove. The right-angle elbow water sealing ring 8 is used to prevent the water entering the inner cavity of the cylindrical body 6 from leaking out of the cylindrical body 6 along the outer surface of the right-angle elbow 7. Of course, the number of right-angle elbow sealing rings 8 can be two or three, and the sealing effect is better. Others are the same as Embodiment 1, and will not be described again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com