Unenclosed carriage roof

An open type, roof technology, applied in the field of railway and road freight, can solve the problems of restricting the efficiency of open type vehicles, cumbersome fixing method of the roof, and restricting the use of the roof, so as to prevent the dust from polluting the environment and avoid the pollution of dust from goods. Environment, rainwater intrusion prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

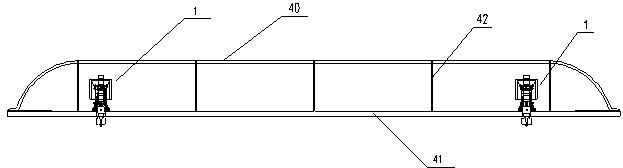

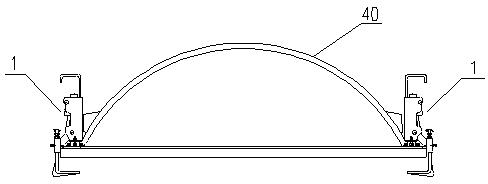

[0030] Such as figure 1 , 2 As shown, the arc cover 40 is in contact with the four peripheral top surfaces of the open compartment through the support surface 41, as the positioning and support of the top cover, the arc cover 40 and the support surface 41 are made of glass fiber reinforced plastics, and the arc cover 40 and the support surface 41 are made of glass fiber reinforced plastics. Reinforcing ribs 42 are installed on the top to ensure the overall strength and rigidity of the arc cover 40; the supporting surface is provided with bolt holes, and several locking devices 1 are distributed and installed on the supporting surface through bolts.

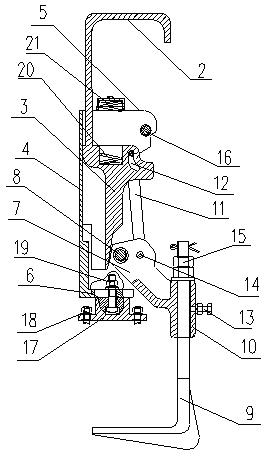

[0031] image 3 , 4 Shown is a specific embodiment of the locking device 1 of the present invention, combined with image 3 , 4 As shown, the specific embodiment includes a seat body, a hook seat 3, a hook 2, a lock hook seat 7, a lock hook 9, and a connecting rod 11; the seat body includes a vertical plate 4, an upper cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com