Valve control type sealed cell vacuum glue filling technology

A sealed battery, valve-controlled technology, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as easy generation of air bubbles, affecting battery appearance quality, battery acid leakage, etc., to reduce the possibility of leakage, Improve the appearance quality and the effect of sealing the terminal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

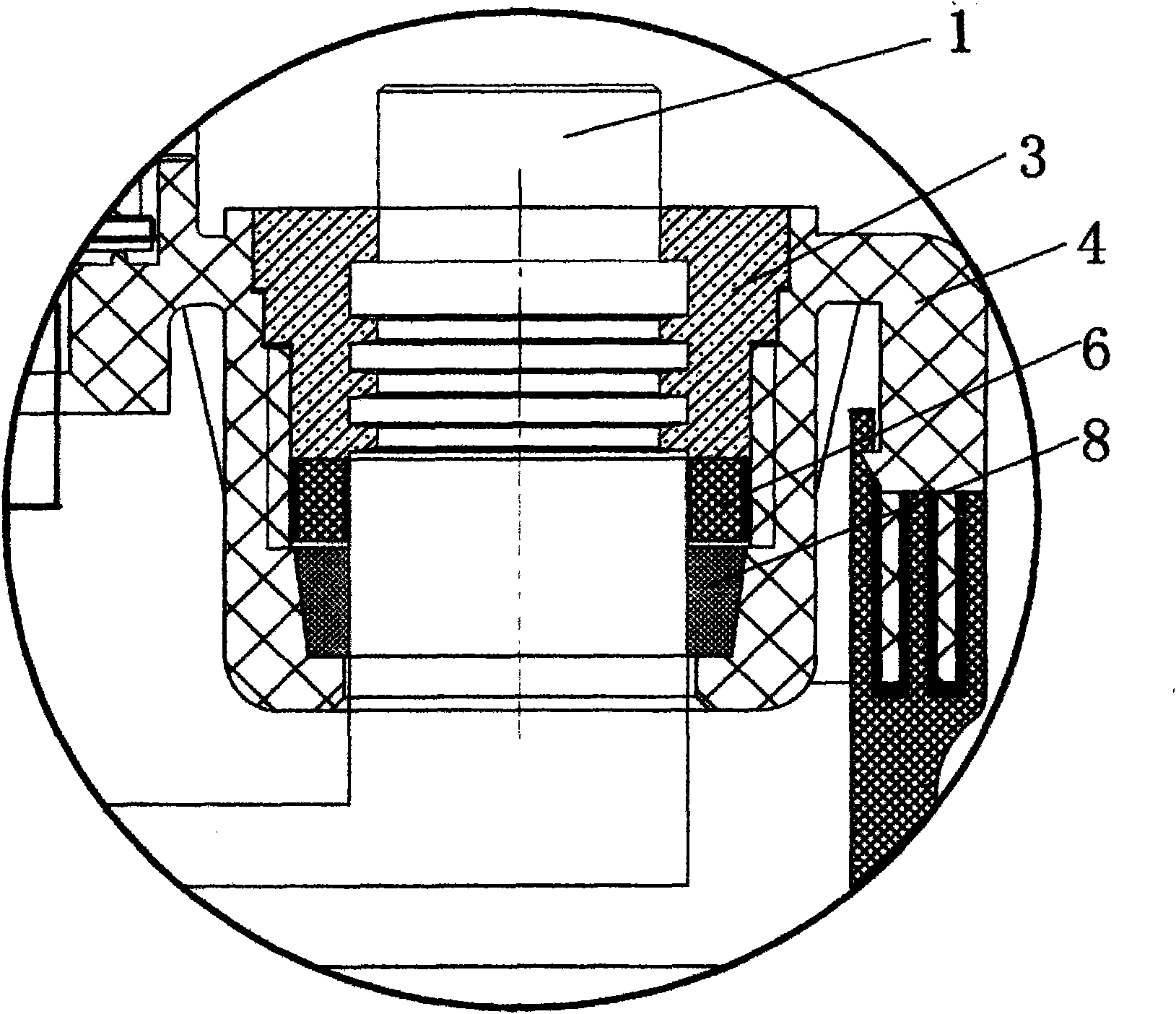

[0014] Attached below Figure 1-2 The present invention is further described, as figure 1 As shown, after using the traditional sealing technology to seal, due to the high viscosity of the epoxy resin glue, the fluidity is not good, and the curing speed of the upper layer glue and the lower layer glue are not consistent, it is easy to generate air bubbles (2), so that the terminal glue (3) cannot be completely sealed. Infiltrate into all the gaps between the battery cover (4) and the battery terminal (1), and the gap (5) and thread between the terminal (1) and the nut (6) still exist between the battery terminal (1) and the battery cover (4). Gap (7).

[0015] Such as figure 2 As shown, after adopting the valve-controlled sealed battery vacuum filling technology of the present invention, the terminal glue (3) completely penetrates into the gap (5) and the thread gap (7) between the terminal (1) and the nut (6), and at the same time, The bubbles (2) in the terminal glue (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com