Method for extracting tea seed oil from tea seeds by microwave processing

A technology of microwave treatment and tea seed oil, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of difficulty in application, limited improvement of oil yield, and method of extracting tea seed oil without using microwave treatment of camellia seed oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

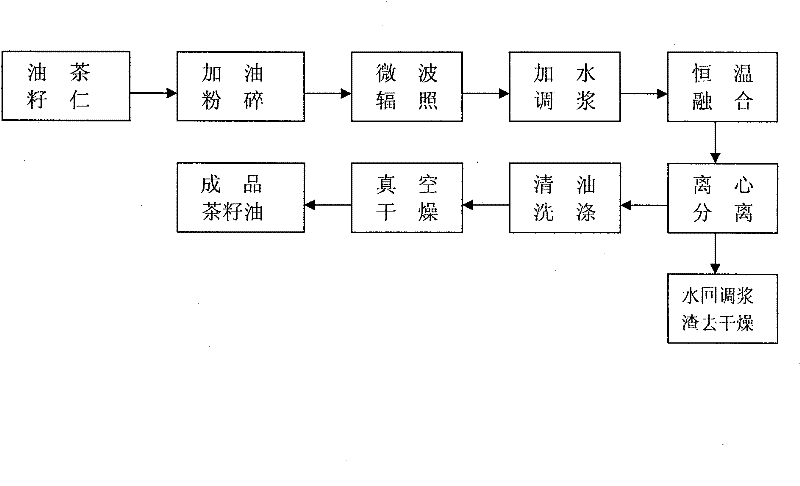

Method used

Image

Examples

example 1

[0020] Weigh 100kg of dehulled tea seed kernels containing 50.6% oil, add 2.5kg of tea seed oil as an oil-inducing agent, mix thoroughly and pulverize to 60-80 mesh, and heat the pulverized material to 55°C by microwave irradiation, and press 3:1 Add 300L of 2.5% brine to adjust the slurry, and then stir and fuse at a constant temperature of 75mir at 55°C and 40-180r / min. The clear oil obtained through centrifugation is washed with water to remove salt and dried in vacuum to obtain 48.2kg of high-quality tea seed oil. Calculate Oil yield rate:

[0021] 48.2kg-2.5kg=45.7kg / 47×100=97.23%

example 2

[0023] Weigh 100kg of dehulled tea seed kernels containing 50.6% oil, add 4.5kg of tea seed oil as an oil-inducing agent, mix well and pulverize to 60-80 mesh, and heat the pulverized material to 85°C by microwave irradiation. Add 350L of water to adjust the pulp. Add alkali to adjust the pH to 8-10, stir and fuse at a constant temperature at 75°C and 120-180r min for 150min, and the clear oil obtained after centrifugation is washed with water to remove the alkali and vacuum dried to obtain high-quality tea seed oil 54.32 kg, calculate the oil yield:

[0024] 54.32kg-4.5kg=49.82kg / 50.6×100=98.46%

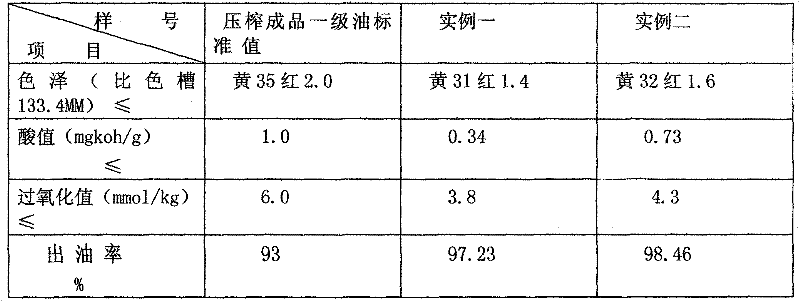

[0025] The main indicators of the tested examples 1 and 2 have exceeded the national standard of the first-grade oil for crushed finished products. The specific data are shown in Table 1,

[0026] Table 1 Comparison table of the main indicators of the national pressed tea seed oil finished product level 1 and examples 1 and 2

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com