Automatic butt welder

A butt welding and automatic technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the welding quality cannot be guaranteed, and achieve the effect of simple structure, convenient use and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with accompanying drawing:

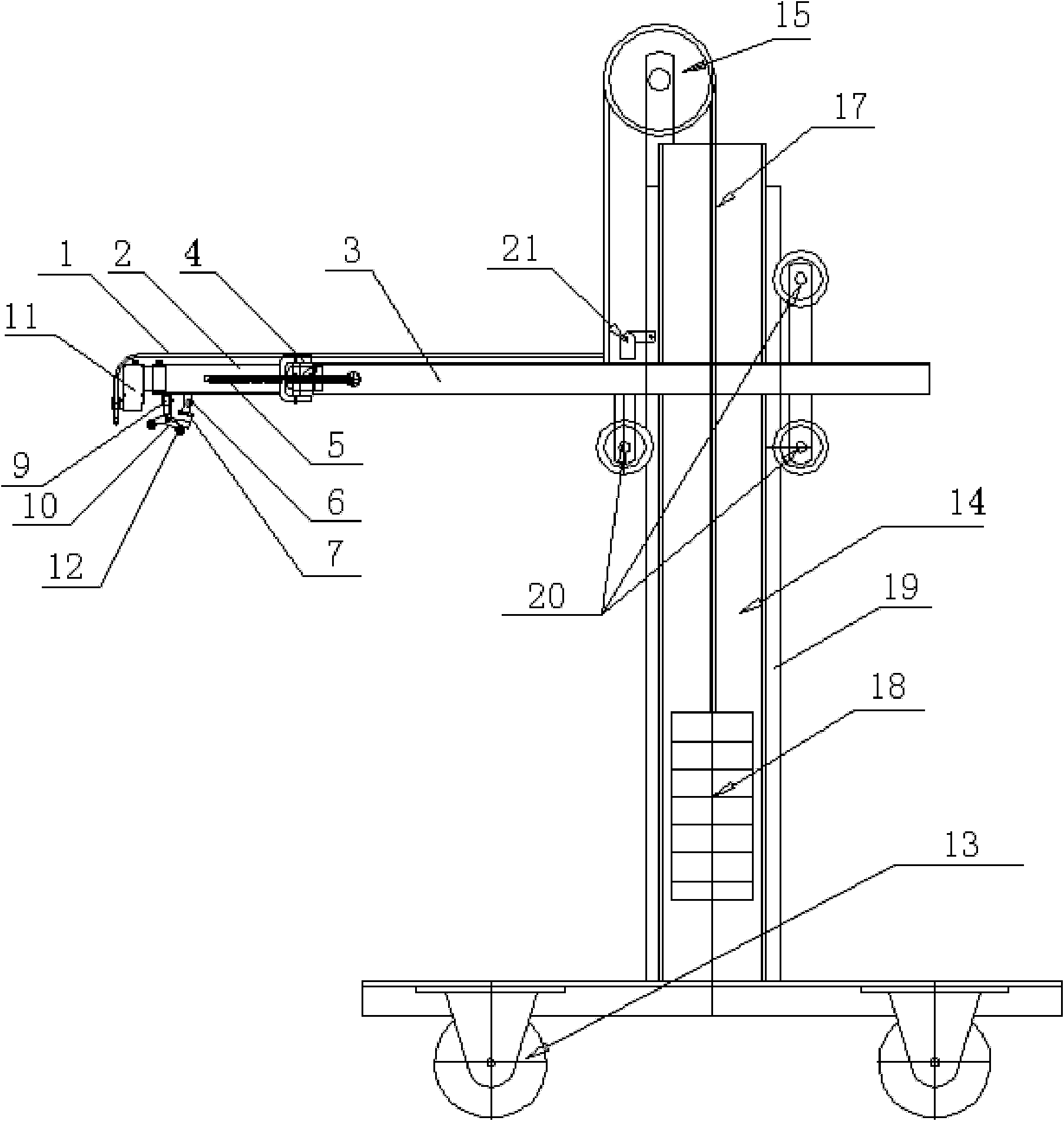

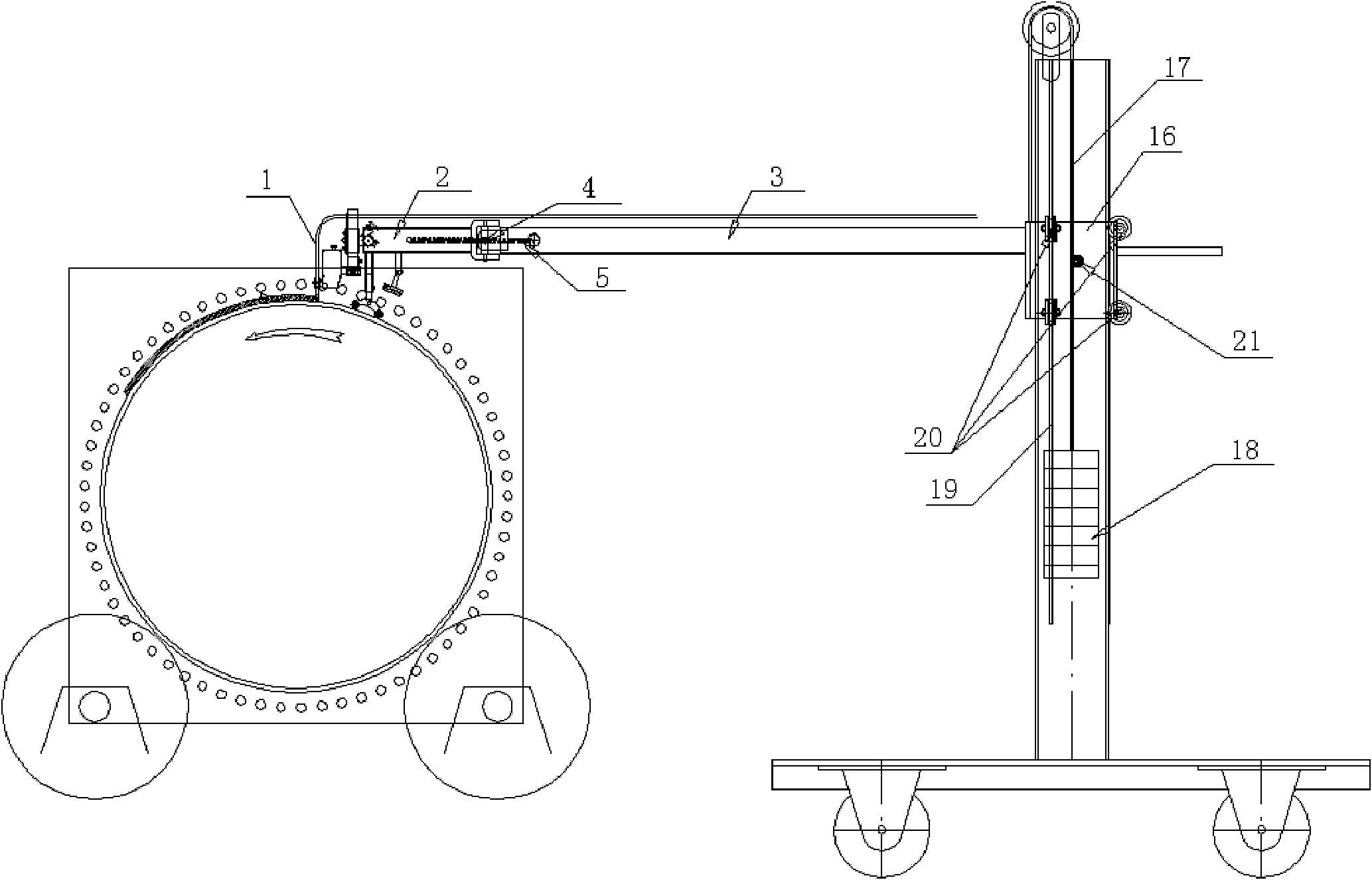

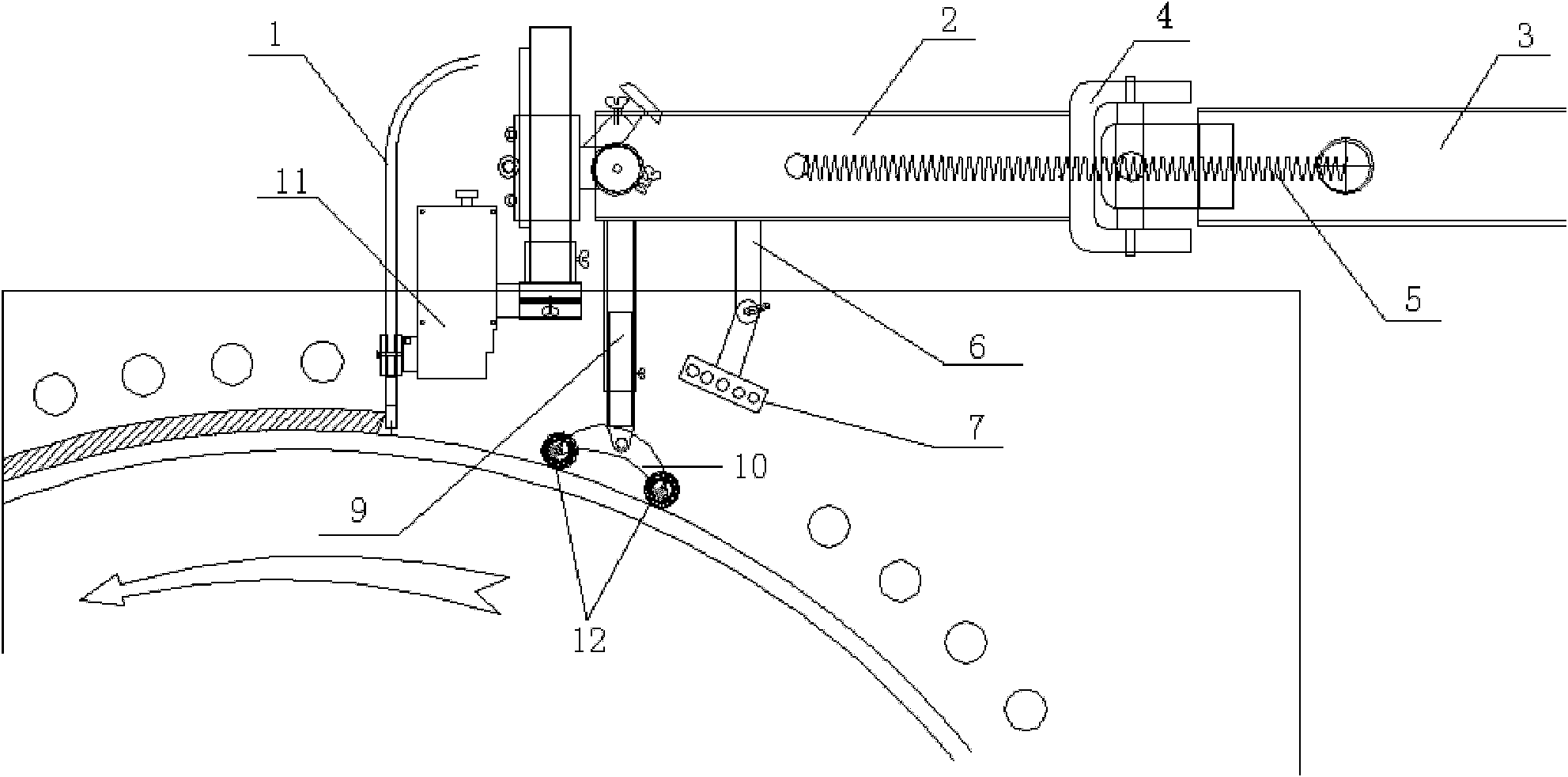

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a straight handle type air-cooled welding torch 1, a lifting device and a cross arm fixed on the lifting device, the straight handle type air-cooled welding torch 1 is fixed on the cross arm, and the described cross arm is passed by the front arm 2 and the rear arm 3 The coupling 4 is connected, the forearm 2 and the rear arm 3 are fixed with a spring 5, the forearm 2 is equipped with a height-adjustable sleeve 6, the lower part of the sleeve 6 is equipped with a horizontal sliding shaft 7, and the top of the horizontal sliding shaft 7 is equipped with a roller 8 , Forearm 2 is equipped with longitudinal telescopic link 9, and the top of telescopic link 9 is equipped with arc bar 10, and the two ends of arc bar 10 are equipped with roller 12.

[0020] The preferred technical solution of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com