Centrifugal bionic coupling pump

A centrifugal, pump casing technology, applied in the field of agricultural or industrial fluid machinery, can solve problems such as reduced efficiency and difficulty, and achieve the effects of improving efficiency, preventing cavitation, and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

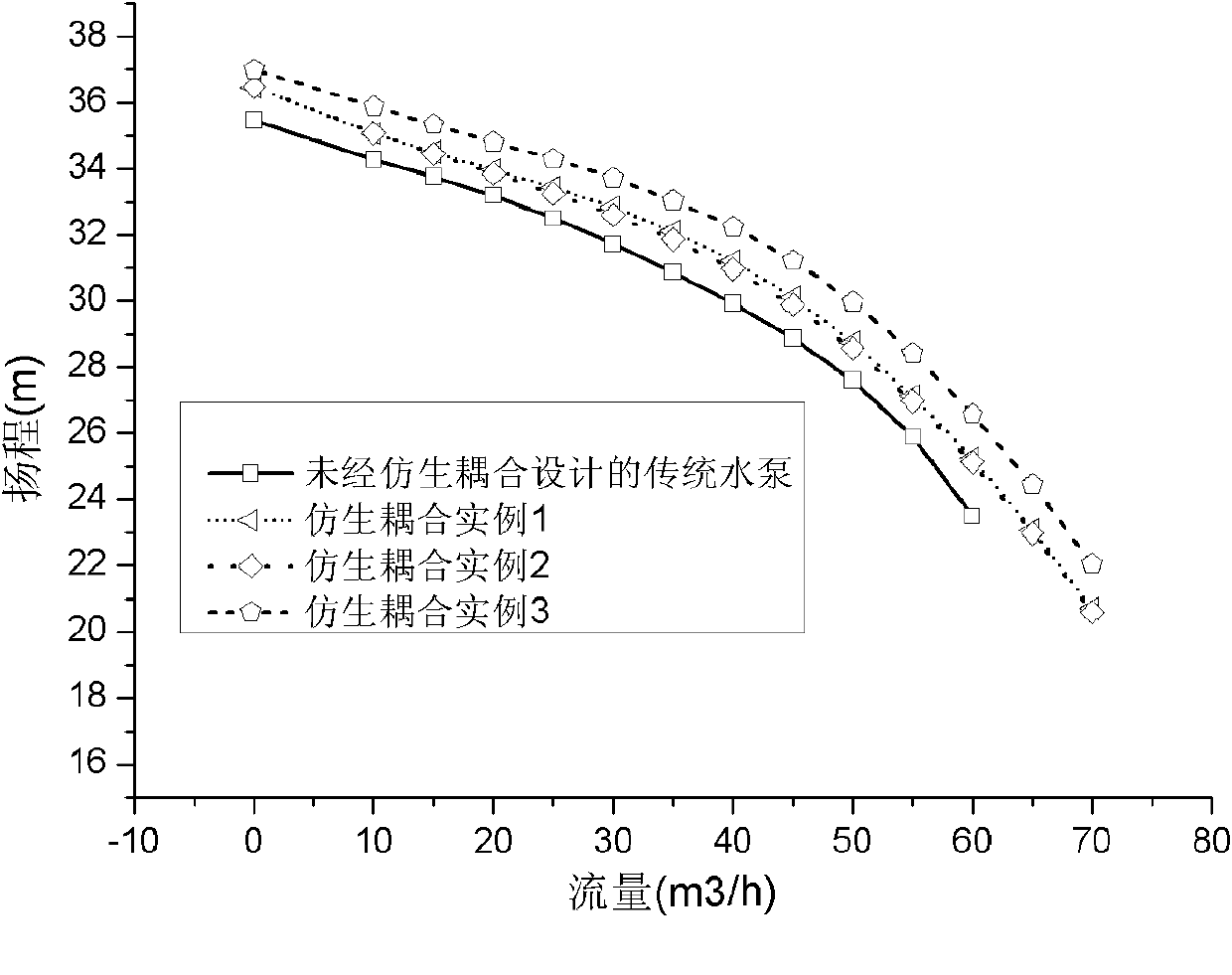

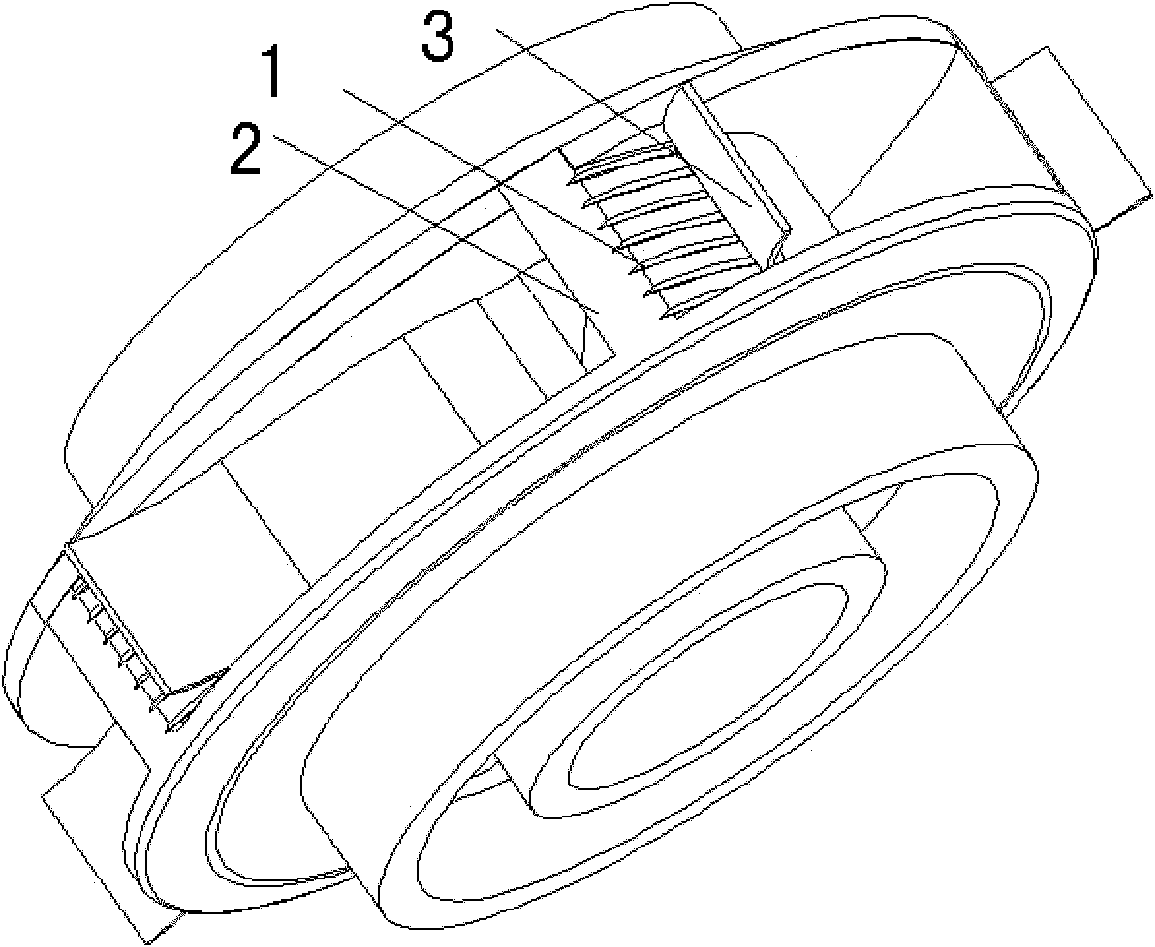

[0027] The rib-shaped bionic non-smooth shape is processed on the side of the impeller. The cross-section of the rib-shaped non-smooth structure is an equilateral triangle, the side length is 0.9mm, and the distance between the ribs is 2.7mm. The resin material with a Shore hardness of 50 is attached. In the impeller of the water pump, in the entire flow section, compared with the traditional water pump without bionic coupling design, the efficiency in the entire effective flow section (the effective flow section of the 200QJ50-26 centrifugal water pump is 40m3 ~ 60m3) has been improved. Such as image 3 shown, at a flow rate of 55m 3 , the efficiency is increased by about 2%, and the flow rate is 65m 3 , the efficiency increased by 5%.

Embodiment 2

[0029] The pit-like bionic non-smooth shape is processed on the side of the impeller, the radius of the pit is 0.5mm, the distance between the pits is 1mm, and the PTU material with a Shore hardness of A50 is coated, which is different from the traditional water pump without bionic coupling design. In the effective flow range, the efficiency is improved, and the flow rate is 60m 3 , the efficiency is increased by about 2%, and the head is improved in the whole flow range, such as Figure 4 shown, especially at flow rates of 60m 3 , The head has been increased by about 1.75m, and the increase rate has reached 6.7%.

Embodiment 3

[0031] The rib-like bionic non-smooth shape is processed on the back of the impeller. The side length of the rib is 1.3mm, the spacing is 2.6mm, and the polyurethane material with Shore hardness of A50 is coated. Compared with the traditional water pump without bionic coupling design, the In the effective flow section, the efficiency is at a flow rate of 60m 3 , the efficiency increased by nearly 2%. In the whole flow section, the head was improved, and the head increased by an average of 3.4m, with an increase of 13.11%.

[0032] The efficiency-flow curves and head-flow curves of the bionic coupled water pumps in the above three implementation examples and the traditional water pumps without coupling design are as follows: image 3 , Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com