Spiral coil type diffusion dialysis membrane assembly and preparation method thereof

A technology of diffusion dialysis and membrane modules, applied in the field of spiral separation membrane modules and their preparation, can solve the problems of low mass transfer efficiency and heavy equipment, and achieve the advantages of increasing mass transfer coefficient, optimizing performance and improving the driving force of mass transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation process of a spiral-wound diffusion dialysis membrane module with an effective membrane area of 0.5 square meters

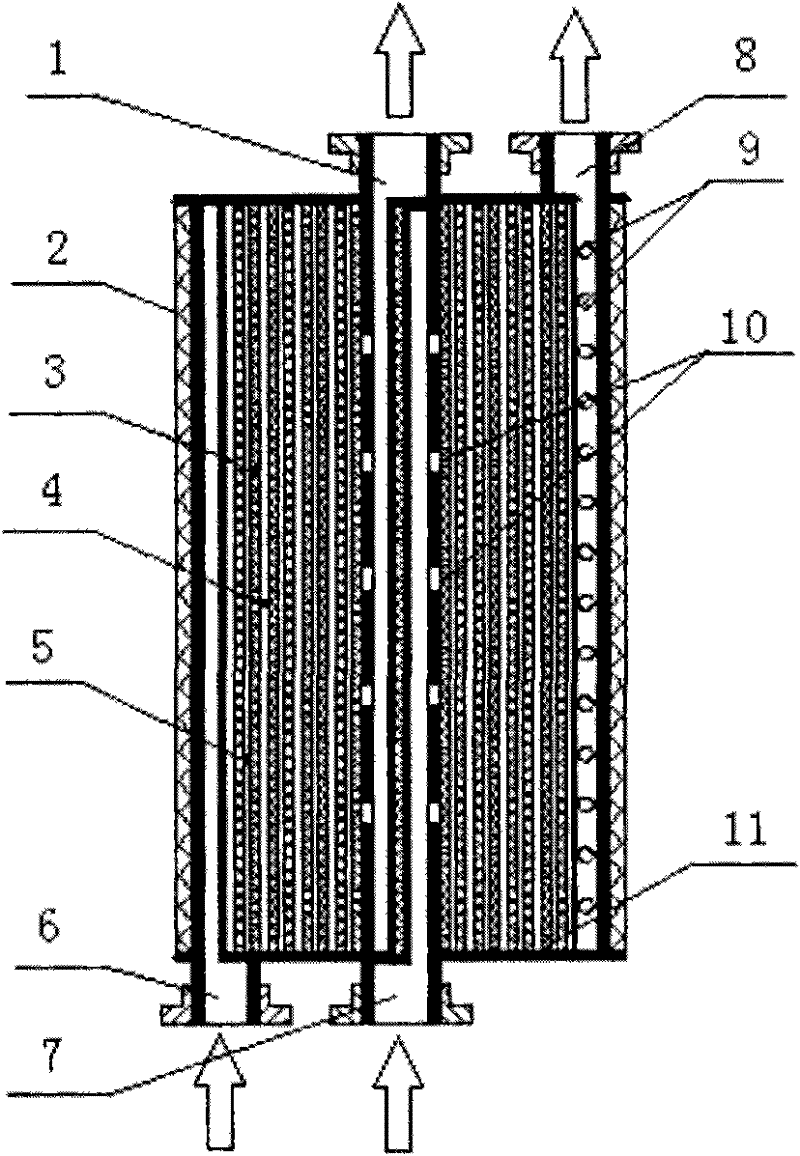

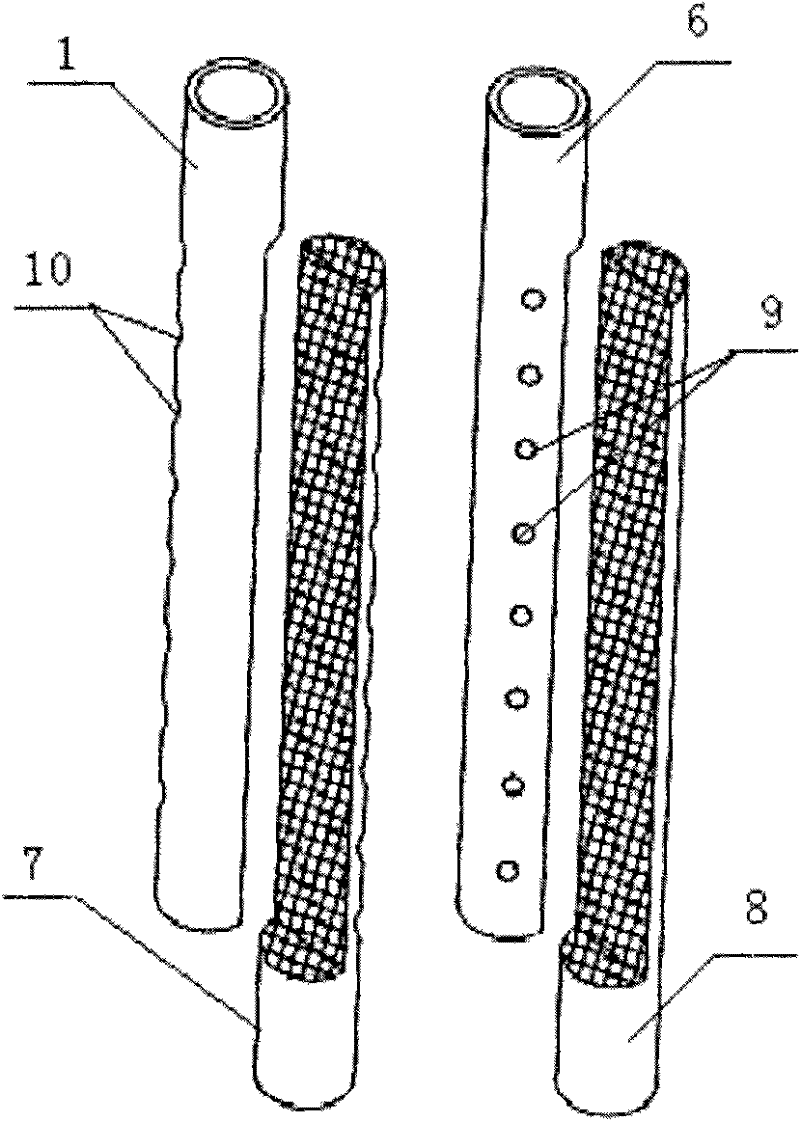

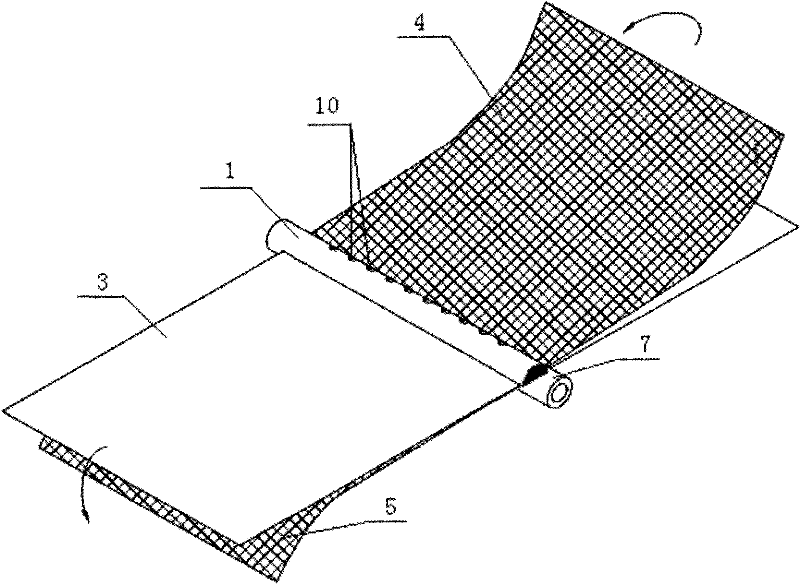

[0025] figure 1 It is a schematic diagram of the overall structure of the spiral-wound diffusion dialysis membrane module of the present invention; figure 2 A schematic diagram of the center pipe and side flow pipe of the spiral-wound diffusion dialysis membrane module is given. Between the two central tubes 1 and 7, an ion exchange membrane 3 and two flow channel spacers 4 and 5 are sandwiched, so that the two flow channel spacers 4 and 5 are respectively arranged on both sides of the ion exchange membrane 3, and the central tube is maintained 1 and 7 as the boundary, the lengths of the ion exchange membranes at both ends are equal, and the ion exchange membrane 3, the flow channel separation net 4, 5 and the central tube 1 and 7 are bonded and fixed; the ion exchange membrane 3 and the flow channel separation net 4 and 5 close...

Embodiment 2

[0037] Example 2: The preparation process of the spiral-wound diffusion dialysis membrane module with an effective membrane area of 10 square meters

[0038] The rolling method adopted in this example is the same as that in Example 1, adopting the DF120 type dialysis negative membrane with a size of 14000×800mm, the central tube and the side flow tube are all polyvinyl chloride plastic tubes with a semicircular cross-section, and the inner diameter It is Φ25mm, and the end is bonded with polyvinyl chloride pipe fittings to convert it into a circular cross section. The flow channel partition is made of polyethylene material, and the effective membrane area of the spiral-wound diffusion dialysis membrane module is 10m 2 , The external dimension is 1000×Φ200mm.

[0039] If the spiral-wound diffusion dialysis membrane module produced in this example is connected in series and parallel, it can be more suitable for the production process of industrial waste acid recovery, and it...

Embodiment 3

[0040] Example 3: Recovery of Industrial Titanium White Waste Acid by Spiral Wound Diffusion Dialysis Membrane Module

[0041] Use as attached Figure 7 The waste acid recovery performance testing device of the spiral-wound diffusion dialysis membrane module shown in , uses the spiral-wound diffusion dialysis membrane module 18 in Example 1 to carry out the waste acid recovery process test, simulates industrial titanium dioxide waste acid solution, and prepares H 2 SO 4 / FeSO 4 Feed liquid samples, the concentrations are shown in Table 1:

[0042] Table 1FeSO 4 / H 2 SO 4 Concentration of Feed Liquid Sample

[0043]

[0044] Inject waste acid and tap water of equal volume into waste acid head tank 17 and water head tank 16 respectively, adjust the flow rate of acid and water, maintain the flow ratio of waste acid and tap water to be about 0.9-1.2, keep the liquid level, and after being stabilized, Determination of sulfuric acid and ferrous sulfate concentration in resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com