Turbocharger

A turbocharger, turboshaft technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of increased manufacturing costs, accumulation, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

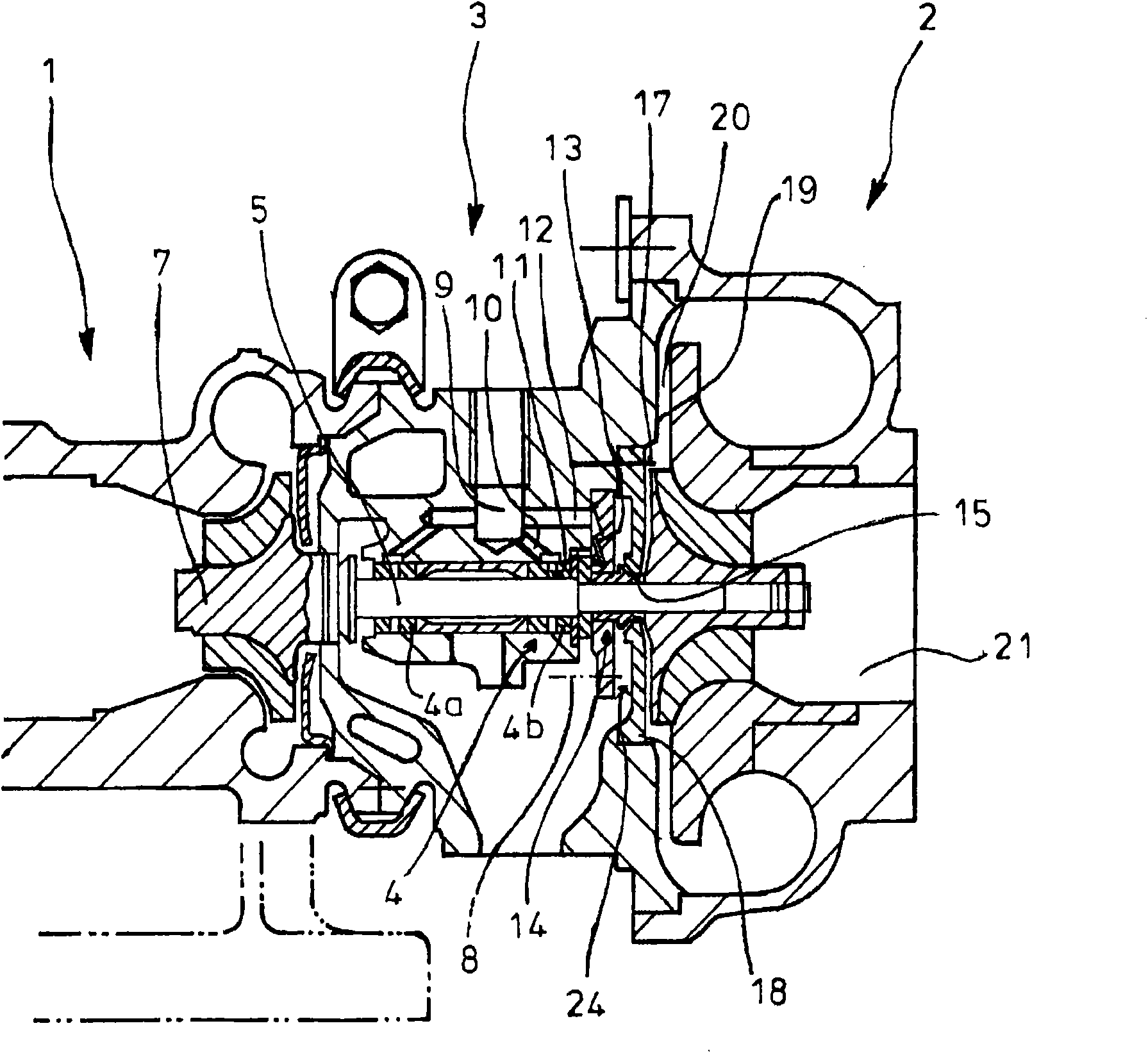

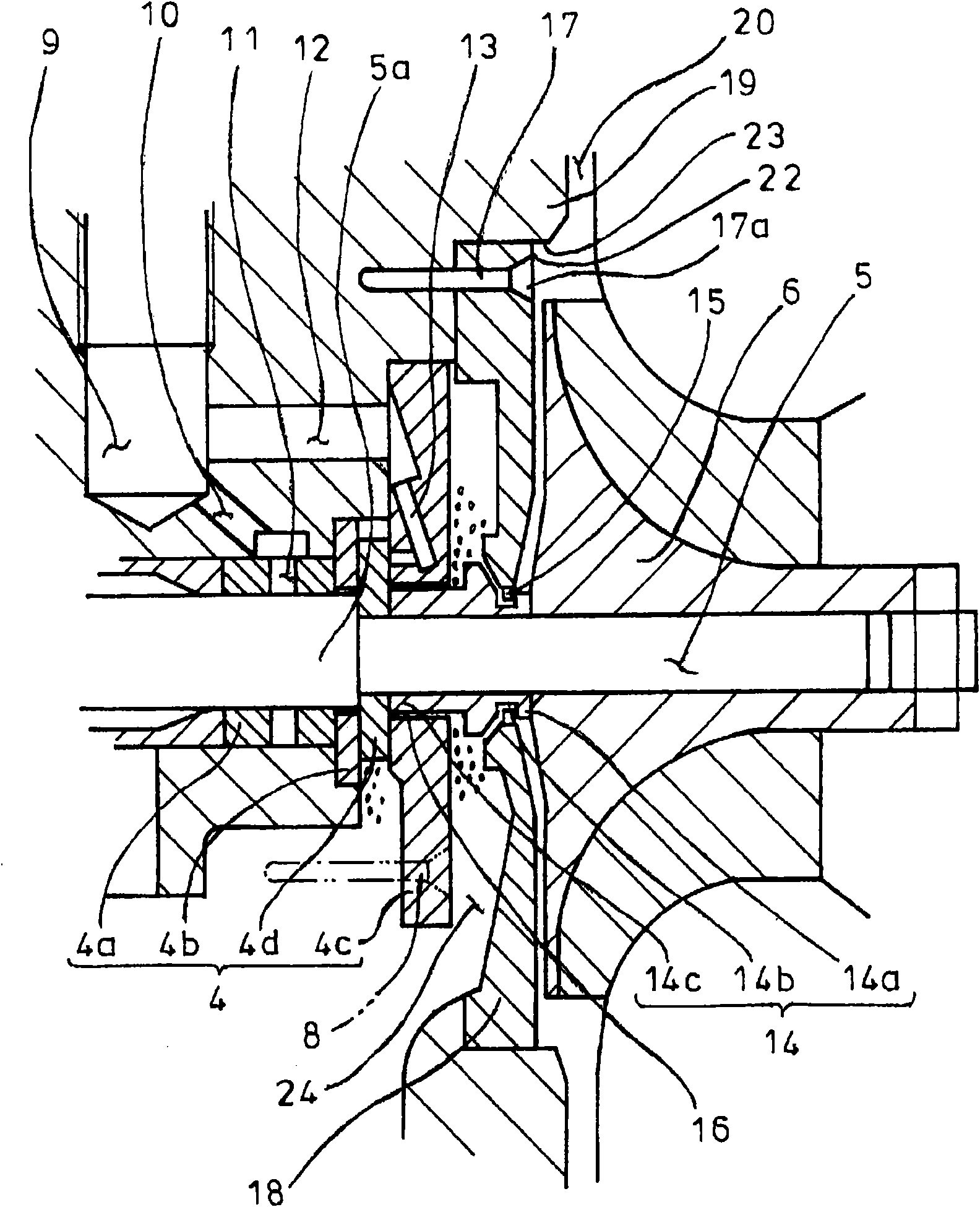

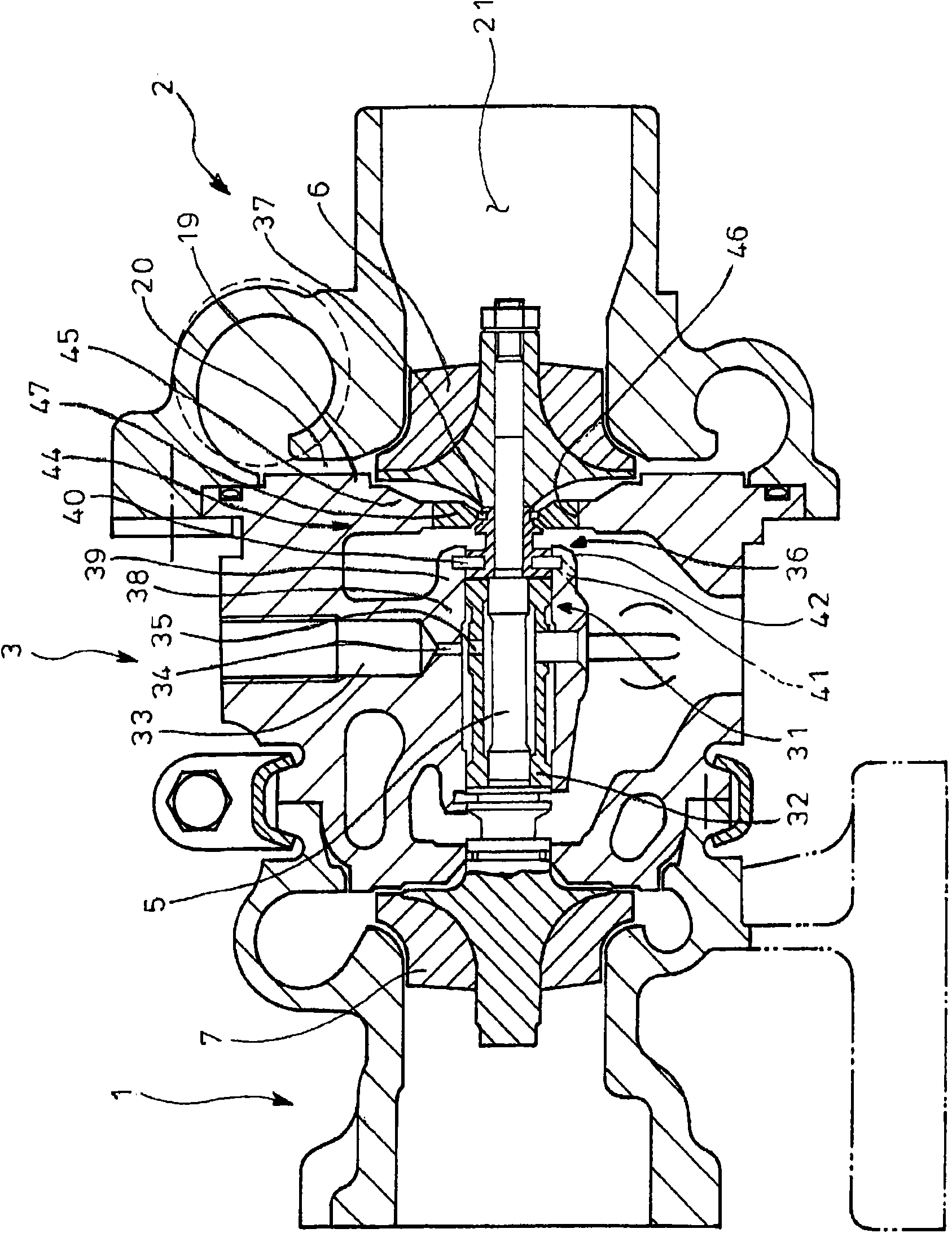

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0049] Figure 3 to Figure 10 is an embodiment of the present invention, where given with figure 1 , figure 2 The parts with the same reference numerals denote the same thing, and in order to solve the problem caused by the discharge of lubricating oil from the bearing part 4 in the past, the turbocharger according to the embodiment of the present invention is configured as follows.

[0050] The turbine shaft 5 is supported inside the bearing housing 3 image 3 , Figure 4 The bearing portion 31 is composed of a floating bush 32 having an integral structure that supports the turbine shaft 5 at two points. On the floating bush 32, lubricating oil is supplied through the supply hole 33 formed in the bearing housing 3 and the flow path 34 extending from the supply hole 33, between the floating bush 32 and the bearing housing 3, and the floating An oil film is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com