Diverter fatigue test bench and operating method thereof

A fatigue test and steering gear technology, which is applied in the field of fatigue test benches, can solve the problems of simulation, failure to achieve simulation results, and large differences in steering gear working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

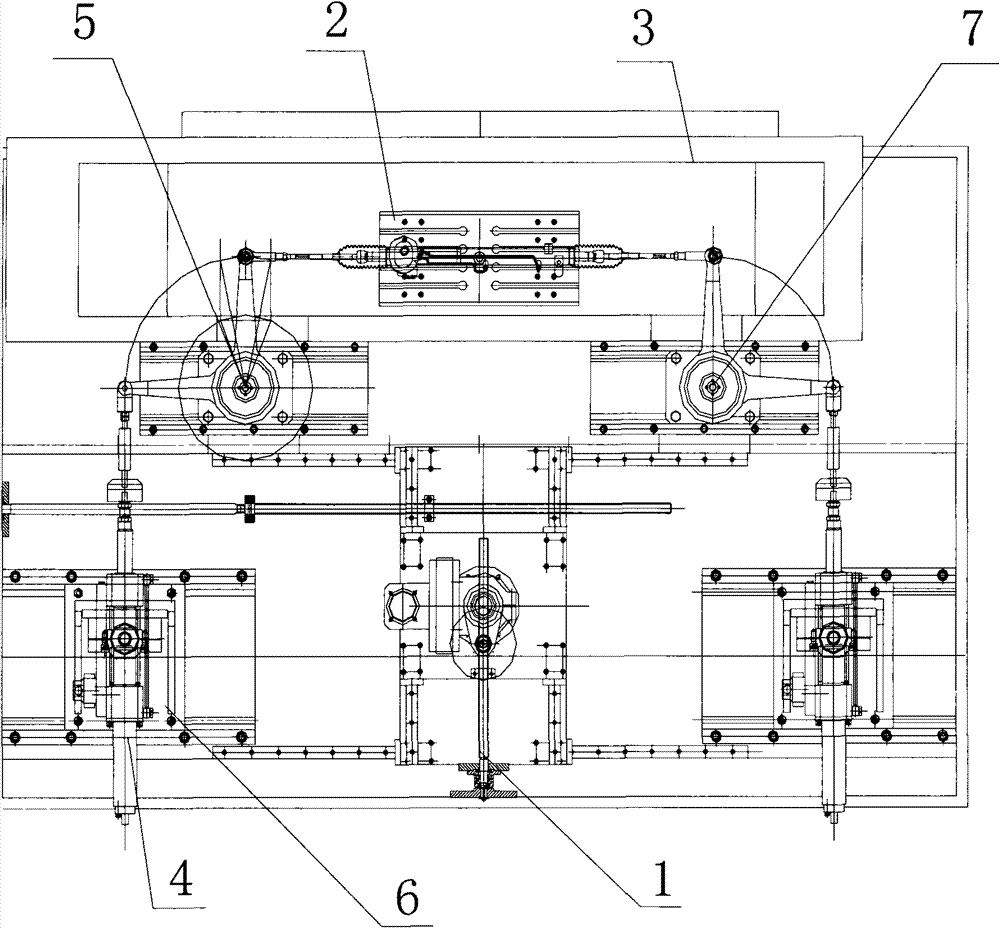

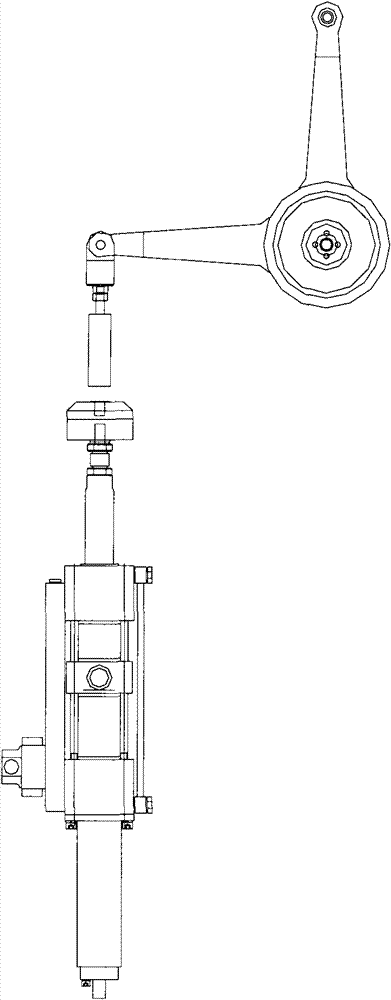

[0027] Depend on figure 1 and figure 2 Combining the structures shown, it can be seen that this kind of steering gear fatigue test bench includes the input end drive device 1, the steering gear fixed workbench 2 and the output end load simulation device, and the output end load simulation device includes the simulated output end horizontal load and the simulated output end vertical impact Load, and the test bench also includes a temperature control device capable of simulating driving environments at different temperatures, that is, a test environment chamber 3 that can accommodate the steering gear fixed workbench 2; the output end load simulation device includes a horizontal load function capable of simulating the output end horizontal load. Actuator 4, a vertical load actuator 5 capable of simulating the vertical impact load at the output end, an actuator mounting support 6 and a rocker mechanism 7, the rocker mechanism 7 is integrally installed at the output end of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com