Differential guide vane section and guide vane adjusting device for vane compressor

A guide vane device and compressor technology, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., can solve the problem of airflow pre-swirl that cannot take into account both blade root and blade tip airflow attack Angle and other problems, to achieve the effect of improving work stability and reliability, widening the flow range, and obvious application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

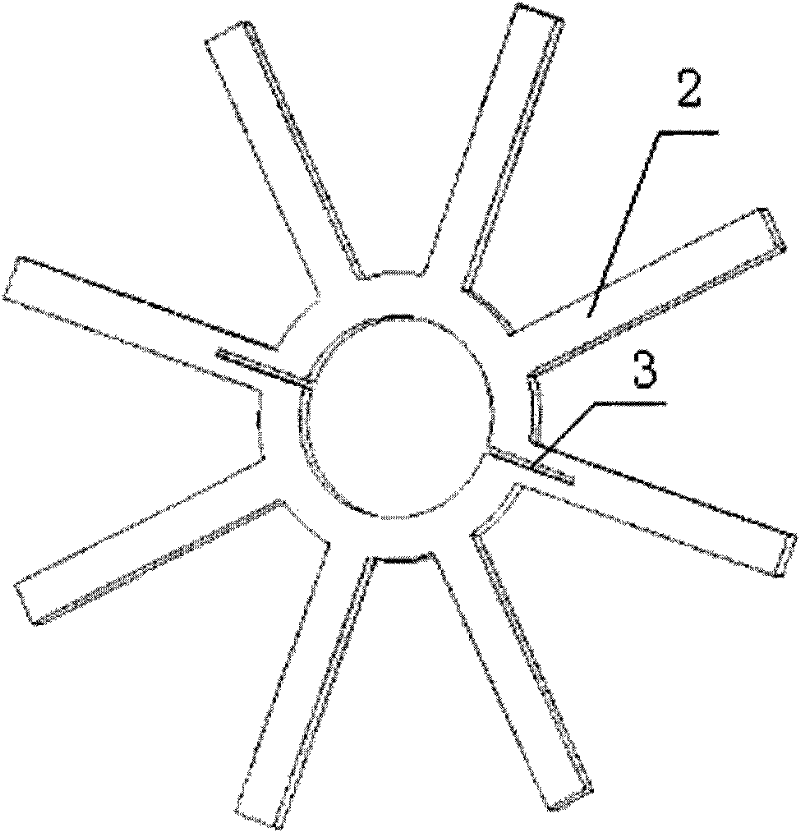

[0017] Such as figure 2 As shown, a differential guide vane slice of a vane compressor, the differential guide vane slice 2 is an overall sheet structure, and there are 8 blades on the differential guide vane slice 2 that are evenly distributed in the circumferential direction along the central axis. The thickness is 3mm, and a through shrapnel slot 3 is machined in the middle of the roots of two blades. The shrapnel slot 3 has a width of 0.9mm and is used to install the shrapnel 10.

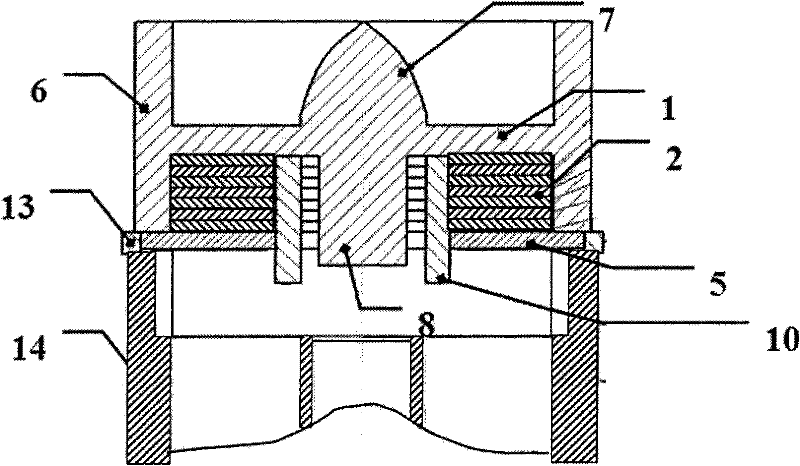

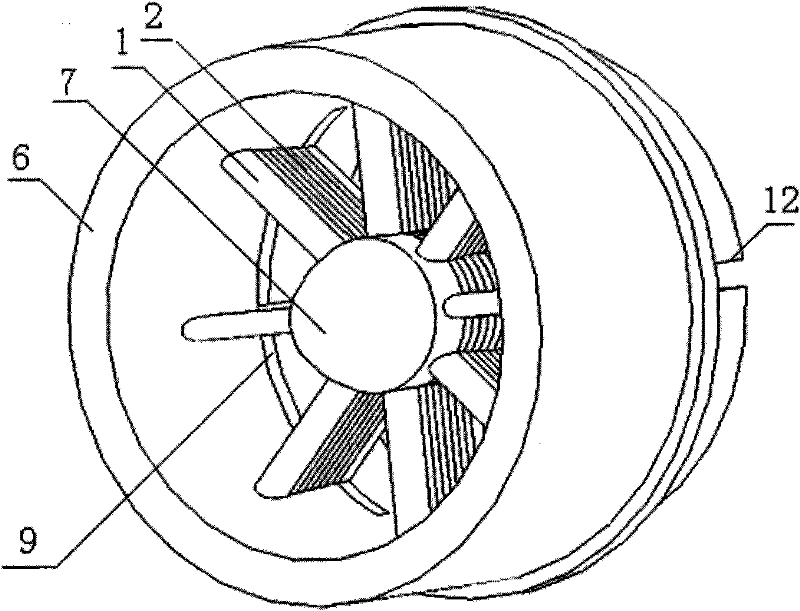

[0018] Such as figure 1 , 3 As shown in 4, an adjustable guide vane device of a vane compressor including the above-mentioned differential guide vane slices, further includes a guide vane holder 1, a shrapnel 10, a rotating rod 5 and a rotating ring 13, and the peripheral equipment is a compressor casing 14; Among them, the guide vane bracket 1 includes a fixed guide vane, an intake sleeve 6, a guide cone 7 and a bracket central axis 8. The intake sleeve 6 has a positioning step on the outer circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com