Imitated-marble tile

A technique of imitating marble and ceramic tiles, which is applied in the field of architectural ceramics, can solve the problems of low simulation degree, wear resistance, lack of fine texture, layering and clarity of natural marble materials, etc., so as to avoid direct wear and prolong service life , the effect of maintaining integrity and natural feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Specifically, the formula of the imitation marble tile that the present embodiment provides is as follows:

[0066] The components of the billet are shown in Table 1:

[0067] Table I

[0068] components

Kaolin

burning talc

content

32%

40%

5%

20%

3%

[0069] Each of the above components is a weight ratio. The weight proportion of the moisture content of the billet powder is 5.5%.

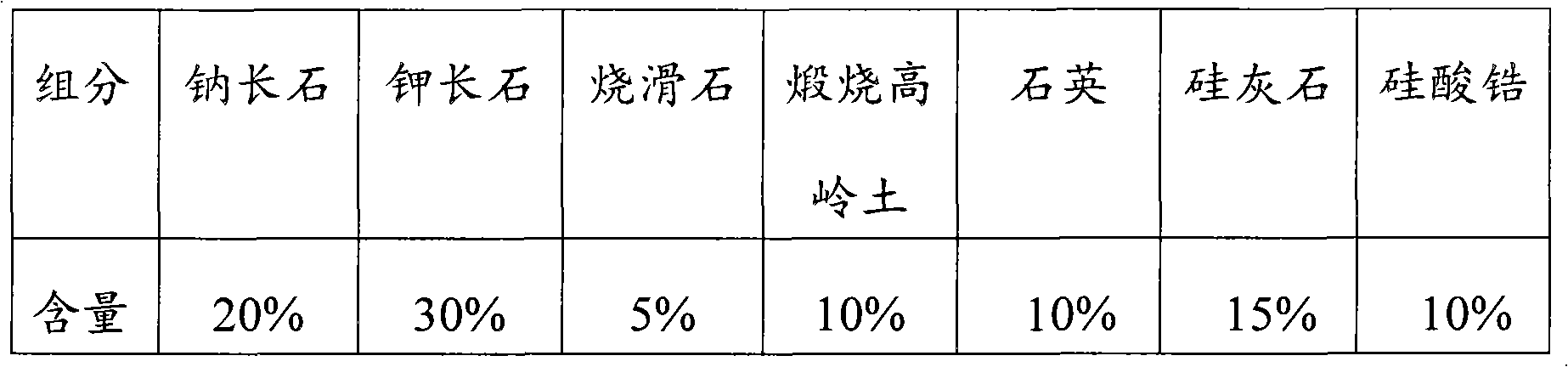

[0070] The composition of the bottom glaze is shown in Table 2:

[0071] Table II

[0072]

[0073] Each of the above components is a weight ratio.

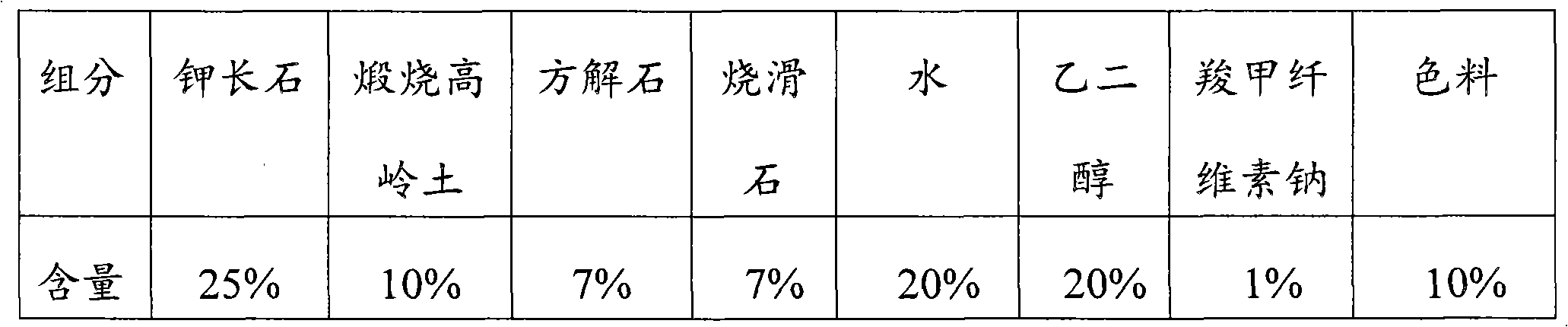

[0074] The composition of flower glaze is shown in Table 3:

[0075] Table three

[0076]

[0077] Each of the above components is a weight ratio.

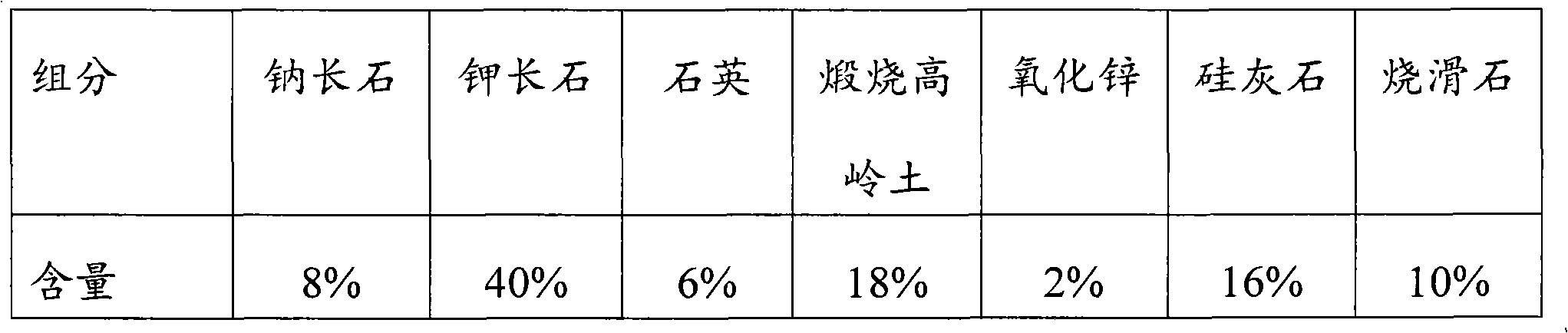

[0078] The components of the transparent glaze are shown in Table 4:

[0079] Table four

[0080]

[0081] Each of the above components is a weight ratio.

Embodiment 2

[0083] Specifically, the formula of the imitation marble tile that the present embodiment provides is as follows:

[0084] The composition of blank is as shown in Table 5:

[0085] Table five

[0086] components

Kaolin

burning talc

content

20%

35%

10%

30%

5%

[0087] Each of the above components is a weight ratio. The weight proportion of the moisture content of the billet powder is 6%.

[0088] The composition of the bottom glaze is shown in Table 6:

[0089] Table six

[0090]

[0091] Each of the above components is a weight ratio.

[0092] The composition of flower glaze is shown in table seven:

[0093] Table Seven

[0094]

[0095] Each of the above components is a weight ratio.

[0096] The components of the transparent glaze are shown in Table 8:

[0097] table eight

[0098]

[0099] Each of the above components is a weight ratio.

Embodiment 3

[0101] Specifically, the formula of the imitation marble tile that the present embodiment provides is as follows:

[0102] The composition of the billet is shown in Table 9:

[0103] Table nine

[0104] components

Kaolin

burning talc

content

35%

35%

5%

23%

2%

[0105] Each of the above components is a weight ratio. The weight proportion of the moisture content of the billet powder is 5%.

[0106] The composition of the bottom glaze is shown in Table 10:

[0107] table ten

[0108]

[0109] Each of the above components is a weight ratio.

[0110] The composition of floral glaze is shown in Table 11:

[0111] Table Eleven

[0112]

[0113]

[0114] Each of the above components is a weight ratio.

[0115] The components of the transparent glaze are shown in Table 12:

[0116] Table 12

[0117]

[0118] Each of the above components is a weight ratio.

[0119] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com