Distributing and discharging device for centrifuge

A technology of unloading device and centrifuge, which is applied in the direction of centrifuge, etc., which can solve the problems of high material distribution, complex structure, vibration, etc., and achieve the effect of uniform material distribution and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

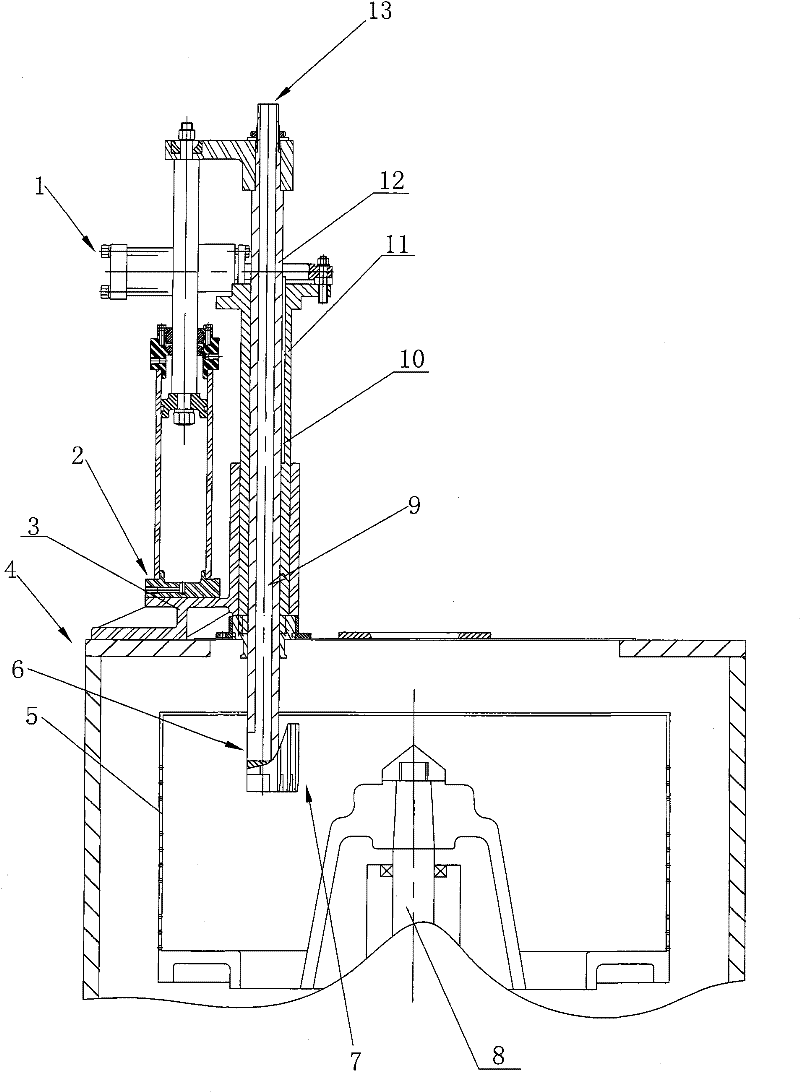

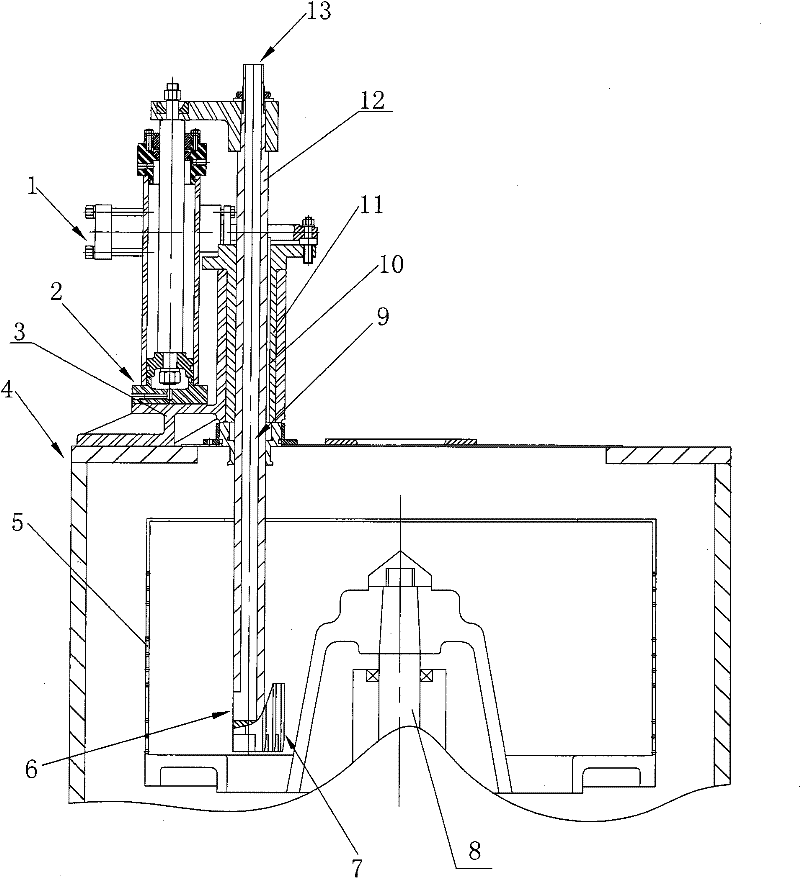

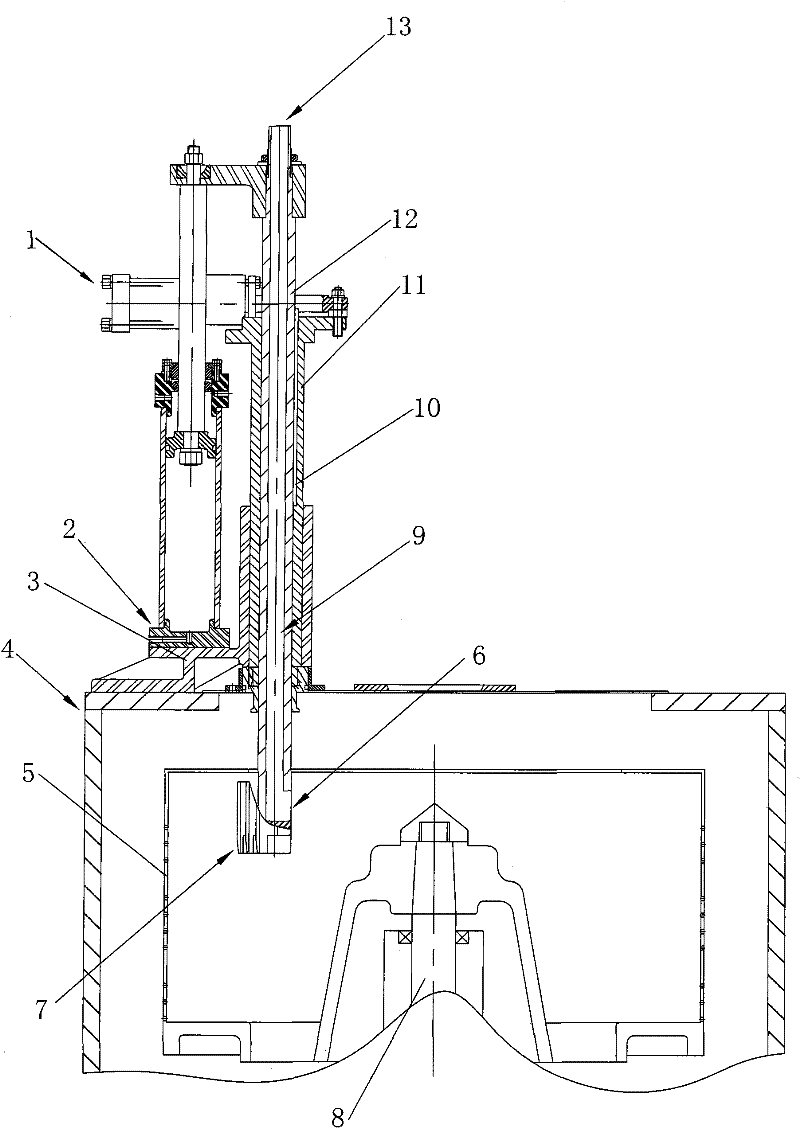

[0022] see Figure 1-3 A distributing and unloading device for a centrifuge is shown, including a casing 4, a machine base arranged on the casing 4, a drum 5 arranged in the casing 4, and a feed pipe 12 inserted into the casing 4 And be fixed on the scraper blade 7 on the feed pipe 12; Feed pipe 12 comprises the feed opening 13 that is positioned at the outside casing 4 and is positioned at the cloth opening 6 in casing 4; An axially moving lifting drive device (can be embodied as a lifting power cylinder) 2, a rotating drive device that drives the feed pipe 12 to rotate around its own axis (shown as a rotating power cylinder) 1, a connecting casing 4, and a lifting drive device 2 and the support seat 3 of the rotary drive device 1; the feed pipe 12 passes through the support seat 3 and the casing 4 and is provided with a through sliding chamber 9; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com