Device and process for washing phosphoric acid tail gas and cogenerating sodium fluosilicate

A technology of sodium fluorosilicate and exhaust gas, which is applied in the direction of phosphoric acid, silicate, phosphorus oxyacid, etc., can solve the problems of normal operation of environmental protection facilities, strong corrosion, difficult storage, etc., to save resources and reduce exhaust gas , Improve the effect of running quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

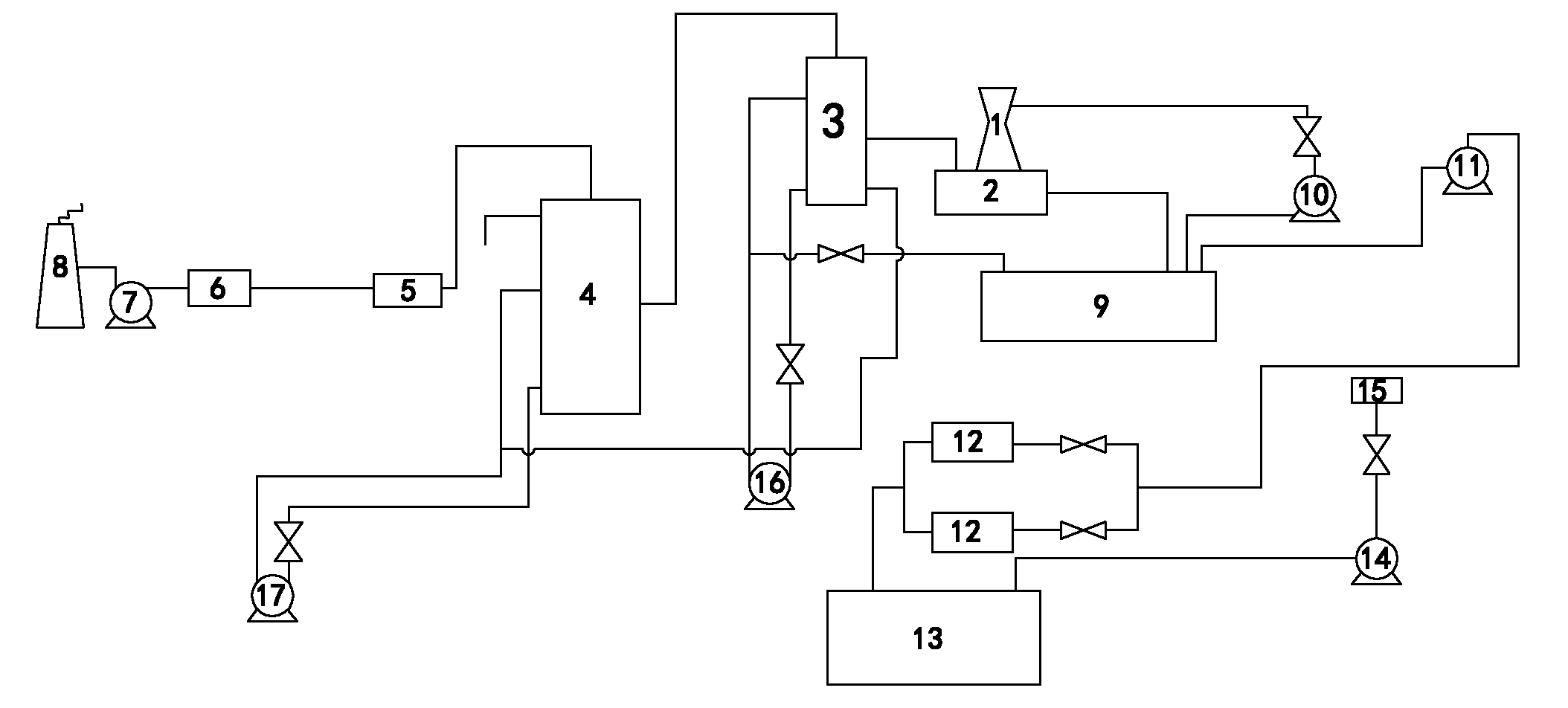

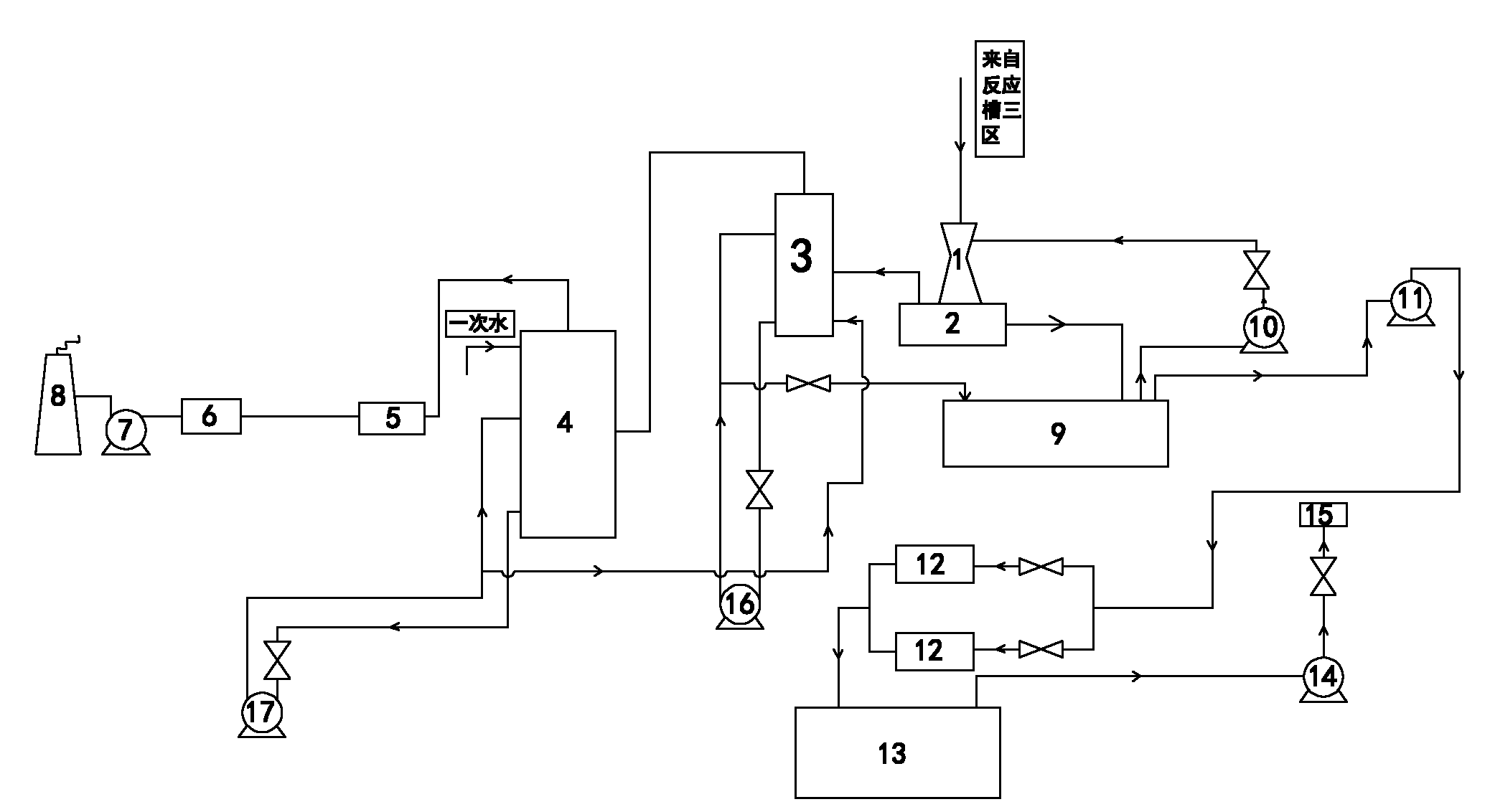

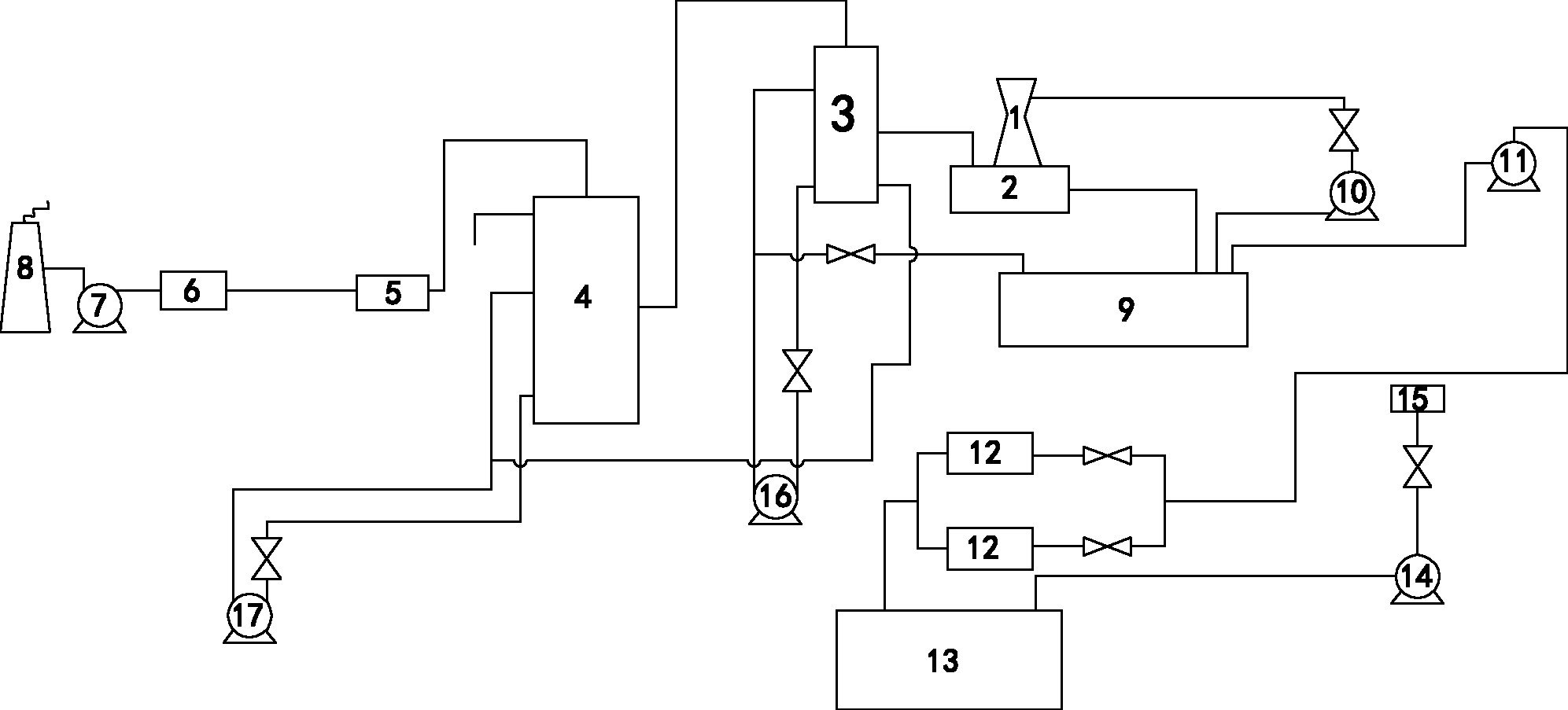

[0022] Example 1 A process for washing phosphoric acid tail gas and co-producing sodium fluorosilicate, the flow chart is as follows figure 2 As shown, the direction of the arrow in the figure indicates the running direction of the material. The specific steps are:

[0023] (1) After the phosphoric acid tail gas is extracted from the third area of the reaction tank, it is washed through the Wen style tube 1, the washing liquid tank 2, the first suction tower 3, and the second suction tower 4, then the fluosilicic acid is dissolved in water, and the washing liquid is recycled; other After the tail gas not dissolved in water enters the tail gas scrubber 5, the defoamer 6, the tail gas blower 7 and the tail gas chimney 8, it is emptied;

[0024] (2) Supplementation of washing liquid: make up water from the second washing tower 4, then divert to the first washing tower 3, then divert from the first washing tower 3 to the washing liquid tank 9, and inject it into the venturi tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com