Constant-pressure helium control device of vacuum system and constant-pressure control method

A vacuum system, constant pressure control technology, applied in the direction of electric fluid pressure control, etc., can solve the problems of reduced helium permeability, inability to ensure the stability of helium pressure in the vacuum system, and inability to ensure the helium pressure in the vacuum system, etc. Achieve the effect of high control sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

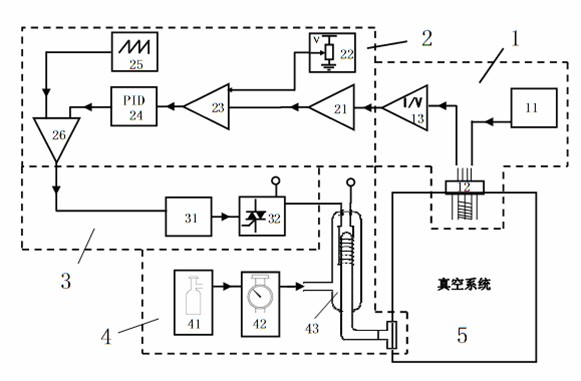

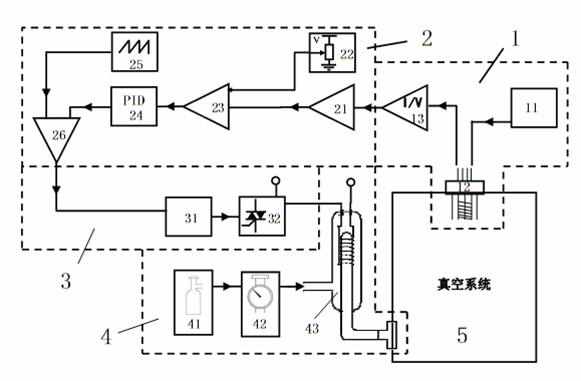

[0018] Depend on figure 1 It can be seen that the vacuum system helium constant pressure control device is composed of signal detection part 1, pulse width modulation signal part 2, power adjustment part 3, helium source 4 and vacuum system 5; signal detection part 1 is composed of vacuum gauge power supply 11, vacuum gauge 12 and a current-voltage conversion circuit 13, the pulse width modulation signal component 2 is composed of a signal amplifier circuit 21, a voltage setting circuit 22, a subtraction circuit 23, a proportional integral differential circuit 24, a sawtooth wave generating circuit 25 and a voltage comparison circuit 26, and the power The adjustment part 3 is composed of a zero-crossing trigger 31 and a triac 32, the helium source 4 is composed of a helium bottle 41, a pressure reducing valve 42 and a helium leak 43; the vacuum gauge 12 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com