Automobile power back door driving mechanism

A driving mechanism and electric technology, which is applied in the direction of power control mechanism, electric components, wing fan control mechanism, etc., can solve the problems of affecting the appearance, the asymmetry of the left and right structural space of the car, and the strict requirements for the installation position, so as to achieve a slender appearance, The effect of novel structure and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

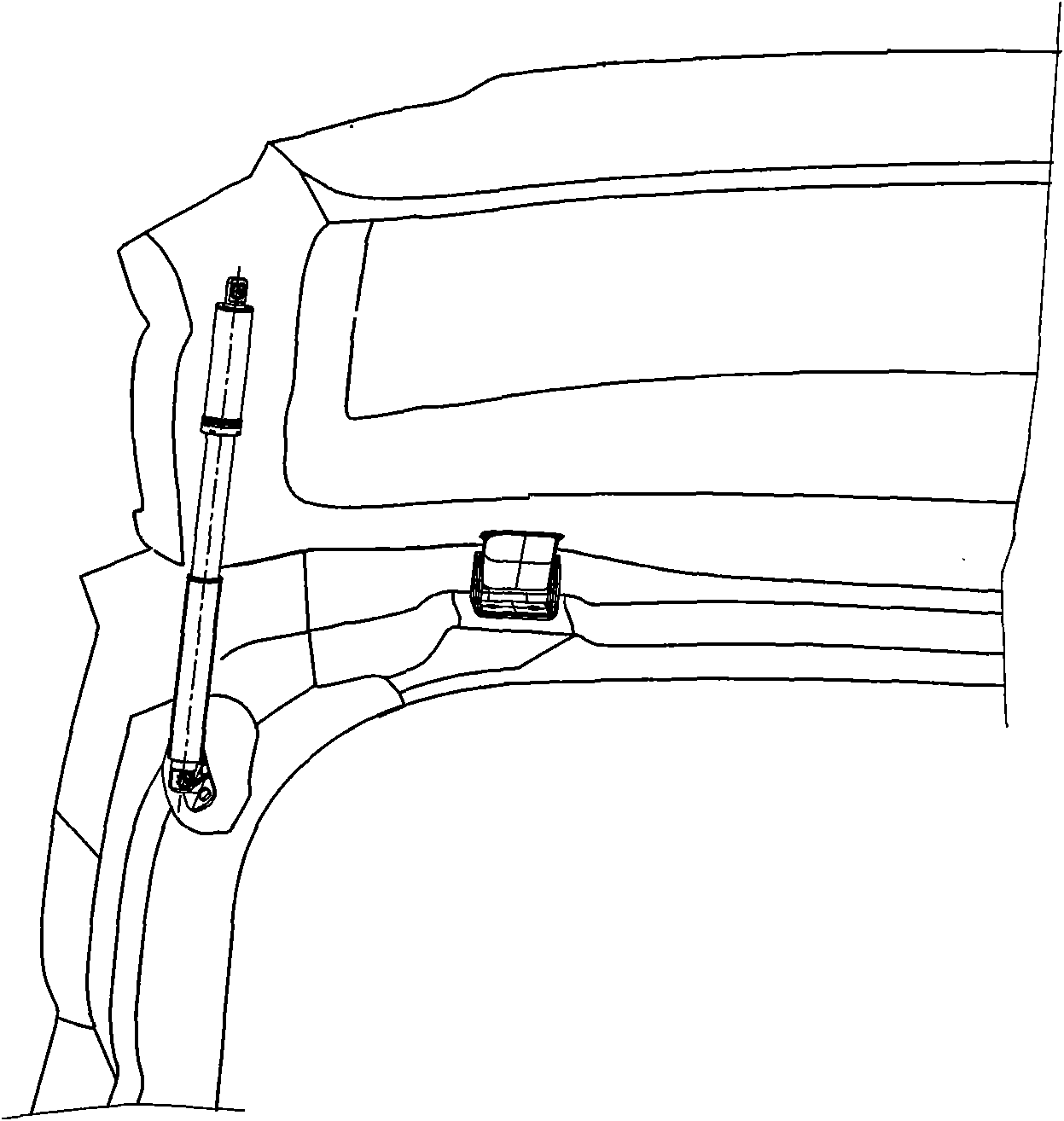

[0020] Electric tailgate driving mechanism of the present invention, as figure 1 As shown, the ball joints 1 at both ends are respectively fixed on the vehicle body and the tailgate, which is basically the same as the installation process of the gas spring of an ordinary SUV. sex.

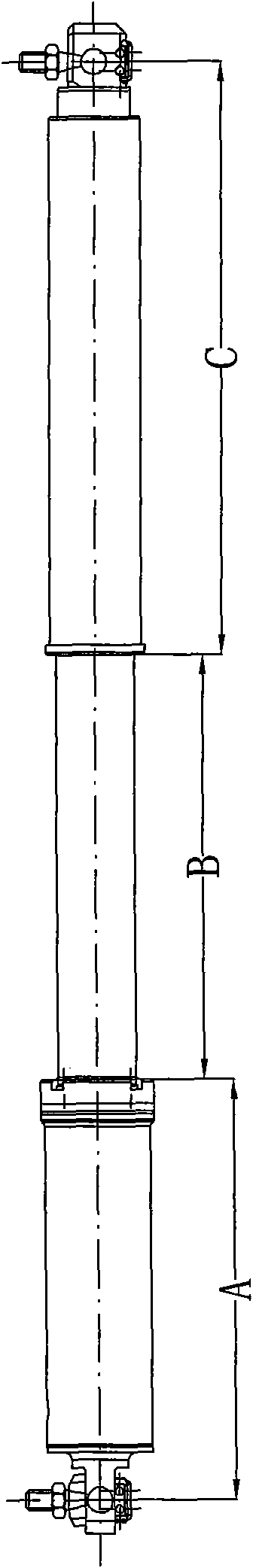

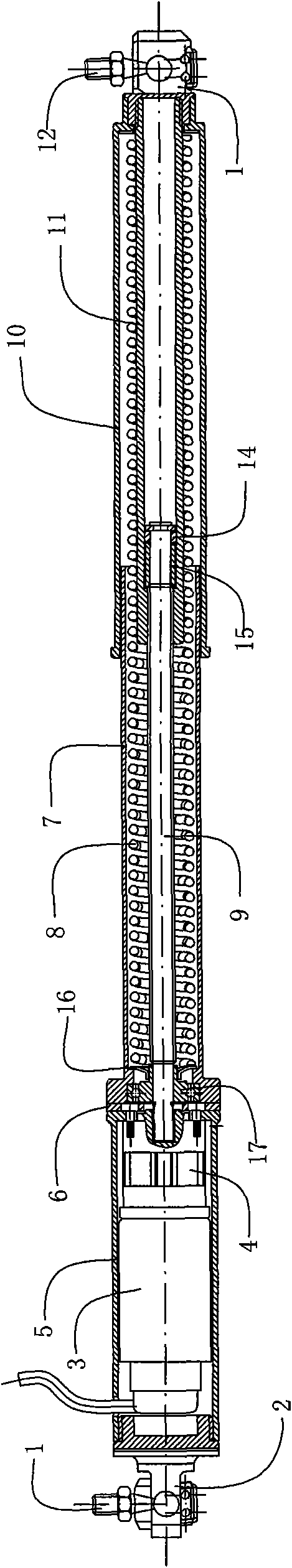

[0021] The power tailgate drive mechanism, such as Figure 2-3 As shown, its shape can include three parts A, B, and C connected in sequence. Parts A and B do not move and are fixed parts. Part C moves relative to A and B with the opening and closing of the tailgate and is a moving part. The length of part B is the length of the stroke of the electric tailgate driving mechanism. The length of extension or shortening of the electric tailgate drive mechanism varies according to the maximum opening angle of the tailgate of each model and the specific installation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com