Method for preparing milk flavor essence, prepared milk flavor essence thereof and related feed flavoring agent

A technology of milk flavor and fragrance, which is applied in the preparation method of milk flavor, milk flavor prepared therefrom, and the field of feed flavor, which can solve the irritation, strong chemical smell, natural aroma and fragrance retention of milk flavor Time difference and other problems, to achieve the effect of enhancing the sense of richness, soft fragrance and long-lasting fragrance, and improving the ability of fragrance retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

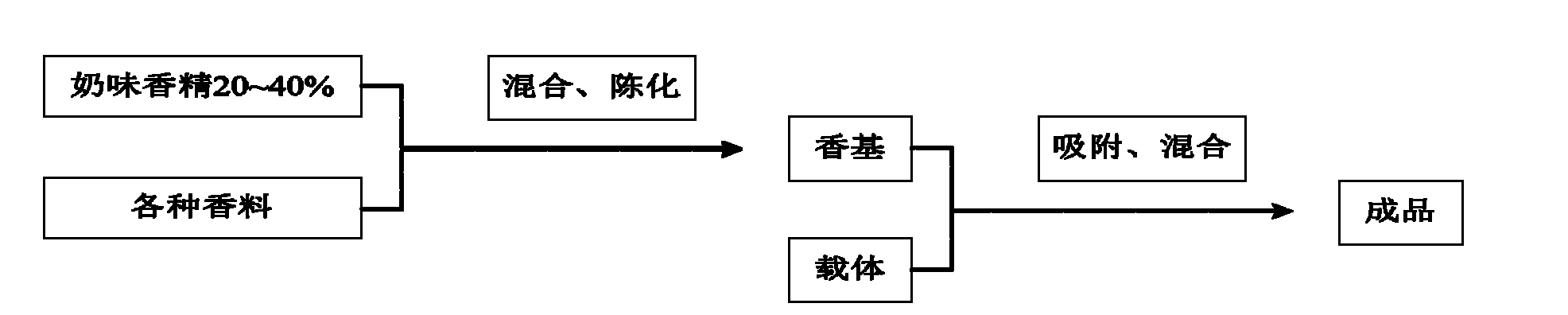

Method used

Image

Examples

Embodiment 1

[0021] Dilute with water in a ratio of 1:1 to 1000g of natural cream, stir and emulsify, then pasteurize at 85°C for 5 minutes, cool down to 40°C after sterilization, add 1.5% lipase Decompose for 4 hours, then raise the temperature to 85°C, keep for 30 minutes to inactivate the enzyme, then dry and concentrate to make a milk flavor essence, and perform sensory evaluation.

[0022] The milk flavor essence prepared above was mixed with ethyl vanillin, capric acid, dodecanoic acid, butyl decanolactone, butyl laurolactone, gamma nonalactone, gamma decanolactone, 2-nonanone , 2-undecanone, and acetoin are mixed, wherein the addition ratio of milk flavor essence is 20%, and the addition ratio of spices is 80%. 35% of ethyl vanillin, 10% of capric acid, 8% of dodecanoic acid, 5% of butyl decanolide, 5% of butyl laurolactone, 5% of gamma nonalactone, 5% of gamma decanolactone 8%, 0.5% of 2-nonanone, 0.5% of 2-undecanone, and 3% of acetoin, and then aging for 12 hours to obtain a fra...

Embodiment 2

[0024] Add ethanol to 1000g of natural cream to dilute at a ratio of 1:1, stir and emulsify, then pasteurize at 85°C for 5 minutes, cool down to 50°C after sterilization, add 0.2% lipase Decompose for 10 hours, then raise the temperature to 85°C, keep for 30 minutes to inactivate the enzyme, then distill and concentrate to make a milk flavor essence, and conduct sensory evaluation.

[0025] The milk flavor essence prepared above was mixed with ethyl vanillin, capric acid, dodecanoic acid, butyl decanolactone, butyl laurolactone, gamma nonalactone, gamma decanolactone, 2-nonanone , 2-undecanone and acetoin, wherein the addition ratio of milk flavor essence is 30%, and the addition ratio of spices is 70%. Among them, ethyl vanillin 30%, capric acid 8%, dodecanoic acid 5%, butyl decanolactone 8%, butyl laurolactone 5%, gamma nonalactone 5%, gamma decanolactone 5%, 0.5% of 2-nonanone, 0.5% of 2-undecanone, and 3% of acetoin, and then aged for 12 hours to obtain a fragrance base, ...

Embodiment 3

[0027] Dilute with water in a ratio of 1:1 to 1000g of natural cream, stir and emulsify, then pasteurize at 85°C for 5 minutes, cool down to 60°C after sterilization, add 10% lipase Decompose for 16 hours, then raise the temperature to 85°C, keep for 30 minutes to inactivate the enzyme, then dry and concentrate to make a milk flavor essence, and perform sensory evaluation.

[0028] The milk flavor essence prepared above was mixed with ethyl vanillin, capric acid, dodecanoic acid, butyl decanolactone, butyl laurolactone, gamma nonalactone, gamma decanolactone, 2-nonanone , 2-undecanone and acetoin, wherein the addition ratio of milk flavor essence is 40%, and the addition ratio of spices is 60%. Among them, 20% ethyl vanillin, 8% capric acid, 6% dodecanoic acid, 6% butyl decanolactone, 5% butyl dodecalactone, 5% propyl nonanolide, 5% propyl decalactone 6%, 0.5% of 2-nonanone, 0.5% of 2-undecanone, and 3% of acetoin, and then aged for 12 hours to obtain a fragrance base, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com