Stapler

A stapler and staple technology, applied in the direction of manufacturing tools, staple staple tools, etc., can solve problems such as wrong binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

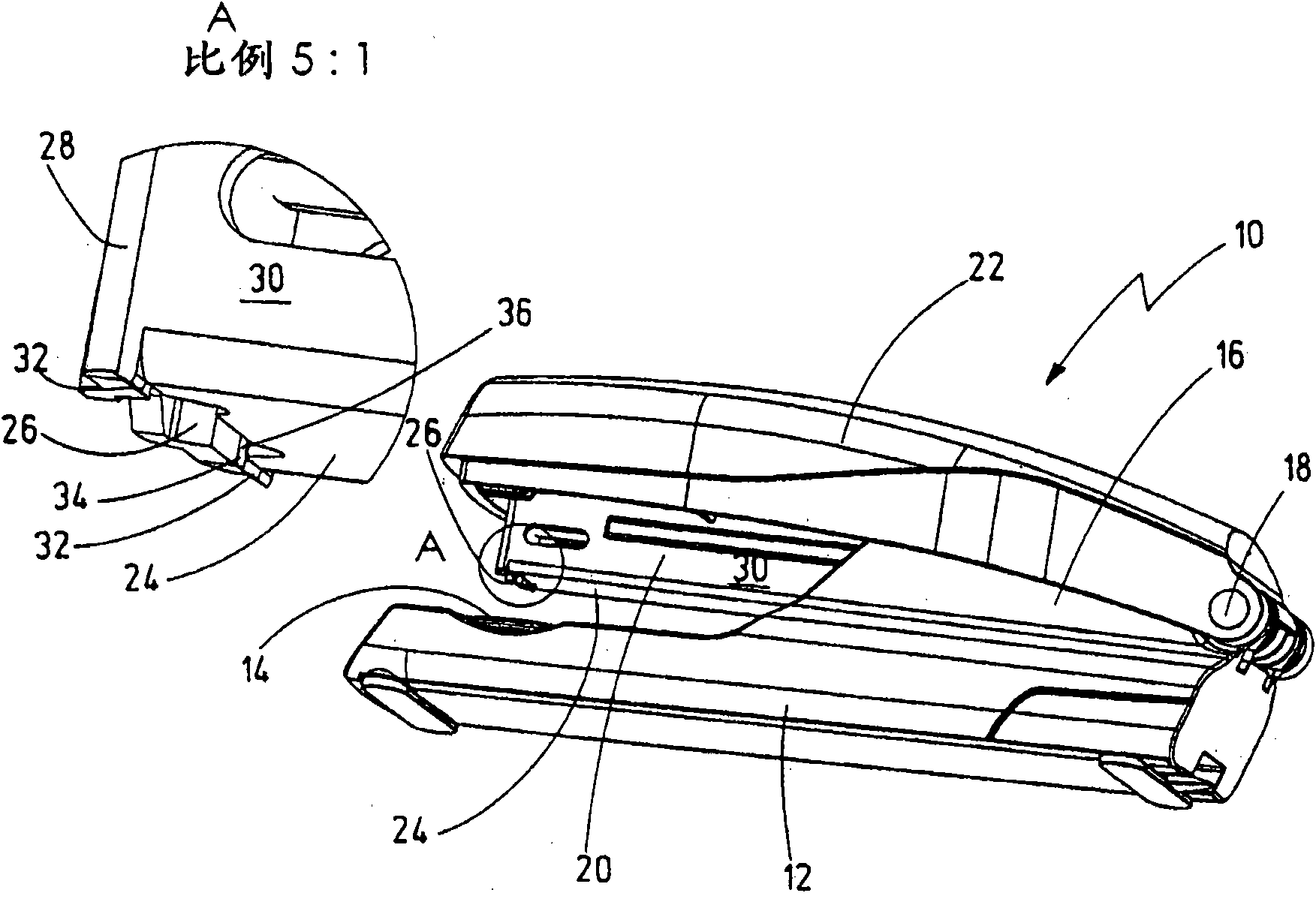

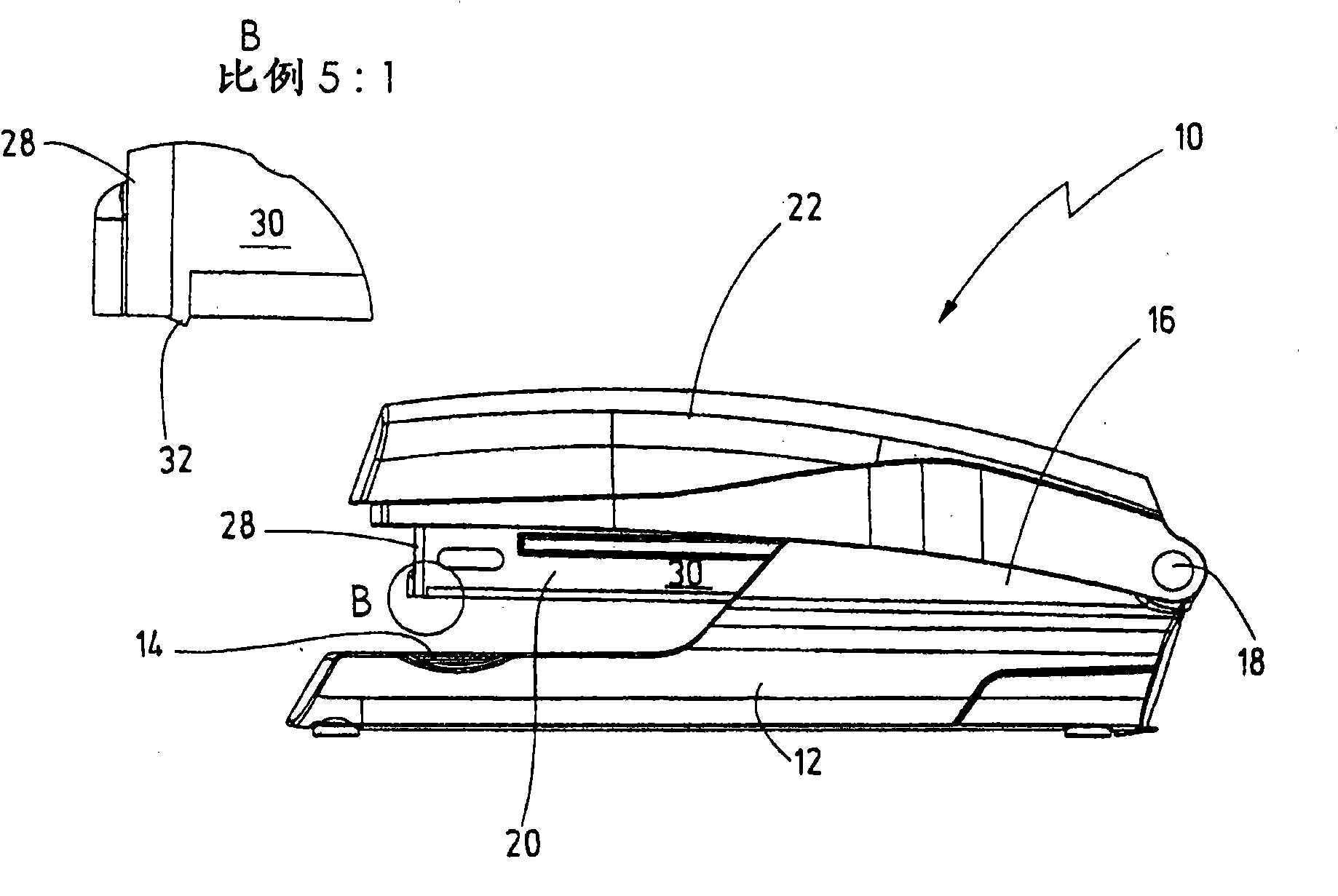

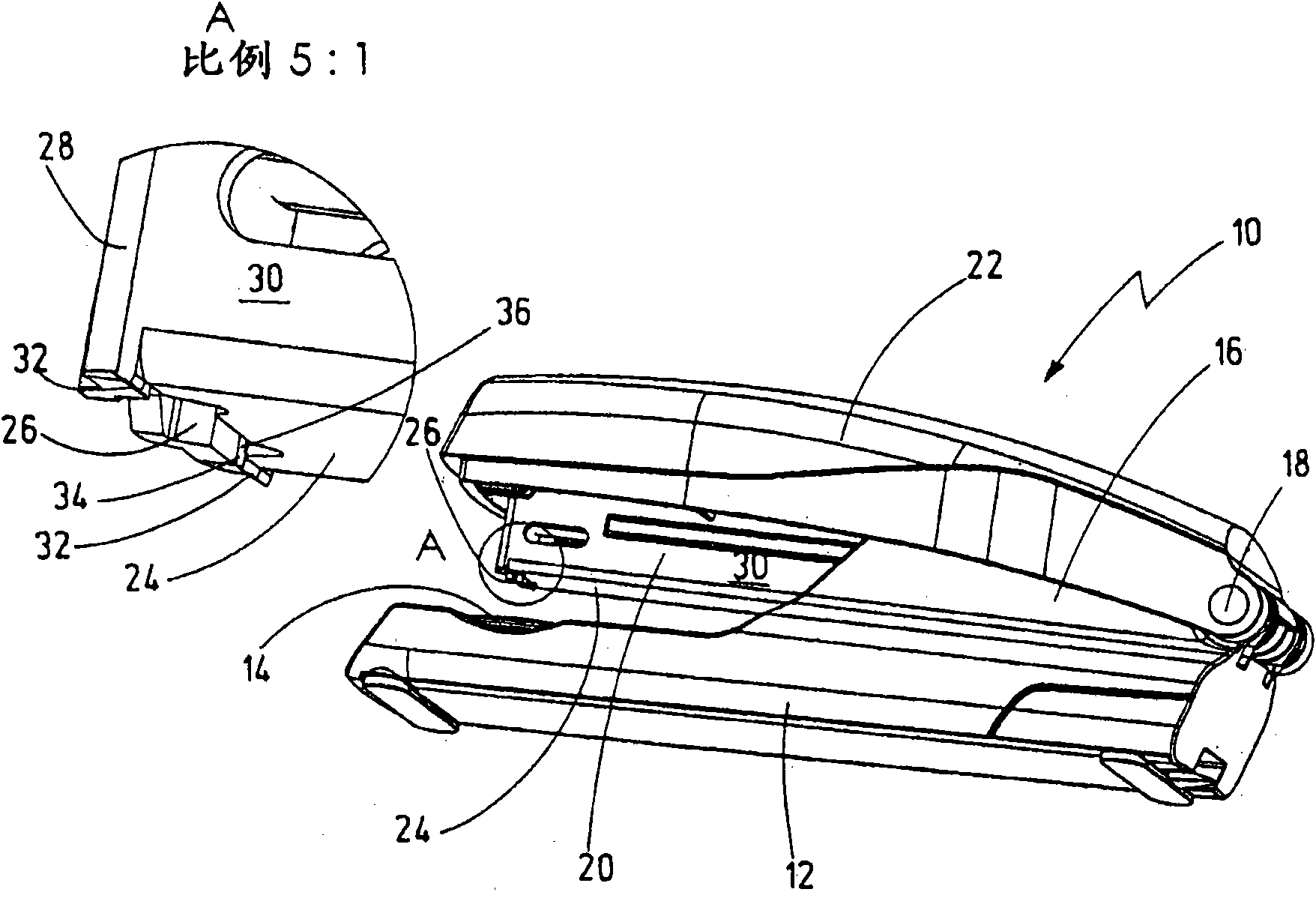

[0012] The stapler 10 shown in the figure has a bottom anvil arm 12 , in the front region of which, on its upper side, a bottom anvil 14 is arranged. In its rear area, the anvil arm 12 has a bearing seat 16 in which a transverse axis 18 is mounted, about which the nail magazine 20 can be pivoted in a limited manner relative to the anvil arm 12 . A driving arm 22 is pivotably supported in the bearing seat 16 around the transverse axis 18 relative to the anvil arm 12 and the nail magazine 20, the driving arm has a plastic cover used as a hand lever and a pair for receiving in the nail magazine 20. The staples exert force on the drive.

[0013] In order to guide the respective foremost staple received in the staple magazine 20 by means of an applied force by the driver, the staple magazine 20 has a staple delivery slot 26 in its bottom wall 24 . The staple output gap is delimited toward the front end of the magazine 20 by a stop plate 28 against which the frontmost staple is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com