Outer wall stone heat preservation decorative one-piece board

A technology of integrated board and stone, applied in covering/lining, construction, building construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

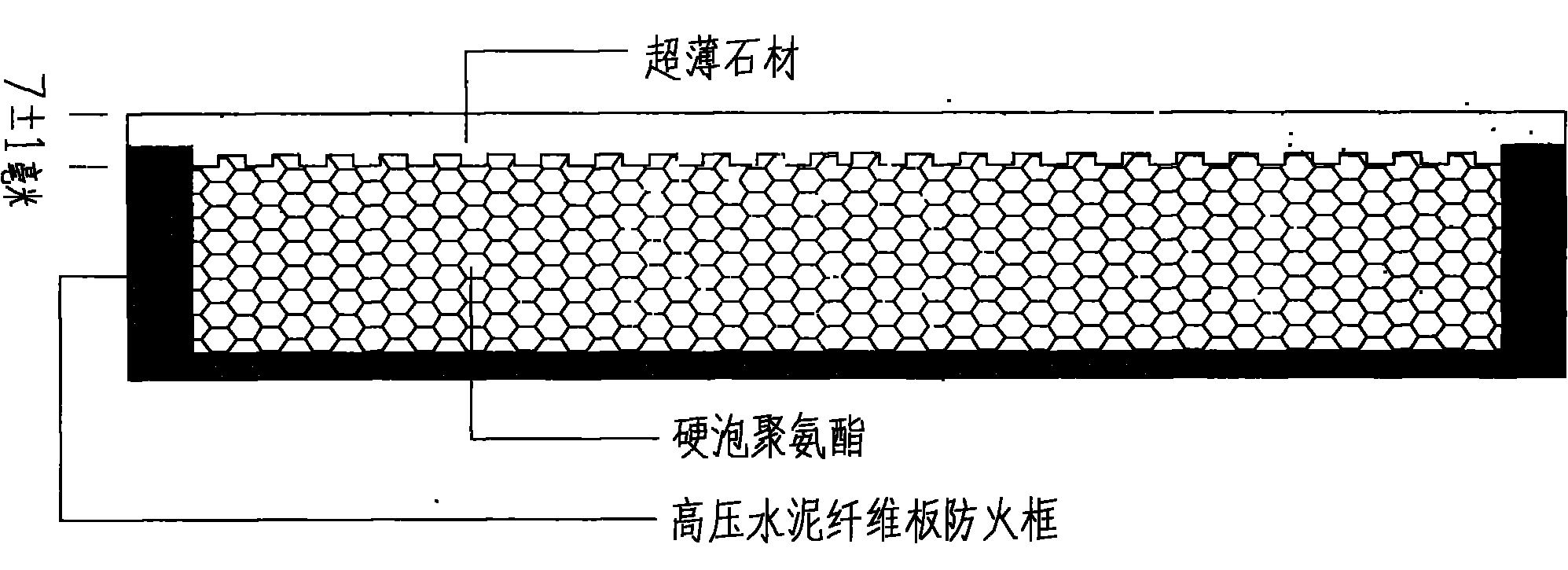

[0005] The first step is to cut the natural stone into ultra-thin stone with a thickness of 7±1 mm.

[0006] The second step is to open a dovetail groove on the back of the stone to increase the bonding strength, and then do a one-centimeter-wide thickness treatment along the back of the processed sheet to make the four sides of the sheet uniform in thickness.

[0007] The third step is to paste a high-pressure cement fiberboard fireproof frame around the thickness-determined part on the back of the thin-slab stone to form a box shape.

[0008] The fourth step is to put the finished box-shaped external wall stone insulation and decoration integrated board into the mold, and inject hard foam polyurethane insulation material.

[0009] The fifth step is to withdraw the mold and arrange the formed products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com