Management and control optimizing method of discrete manufacture production

An optimization method, a manufacturing technology, applied in the direction of instruments, data processing applications, forecasting, etc., can solve problems such as large deviations between production plans and actual production, unsmooth production processes, and unbalanced equipment capabilities, so as to reduce production costs and Inventory, lean production control, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

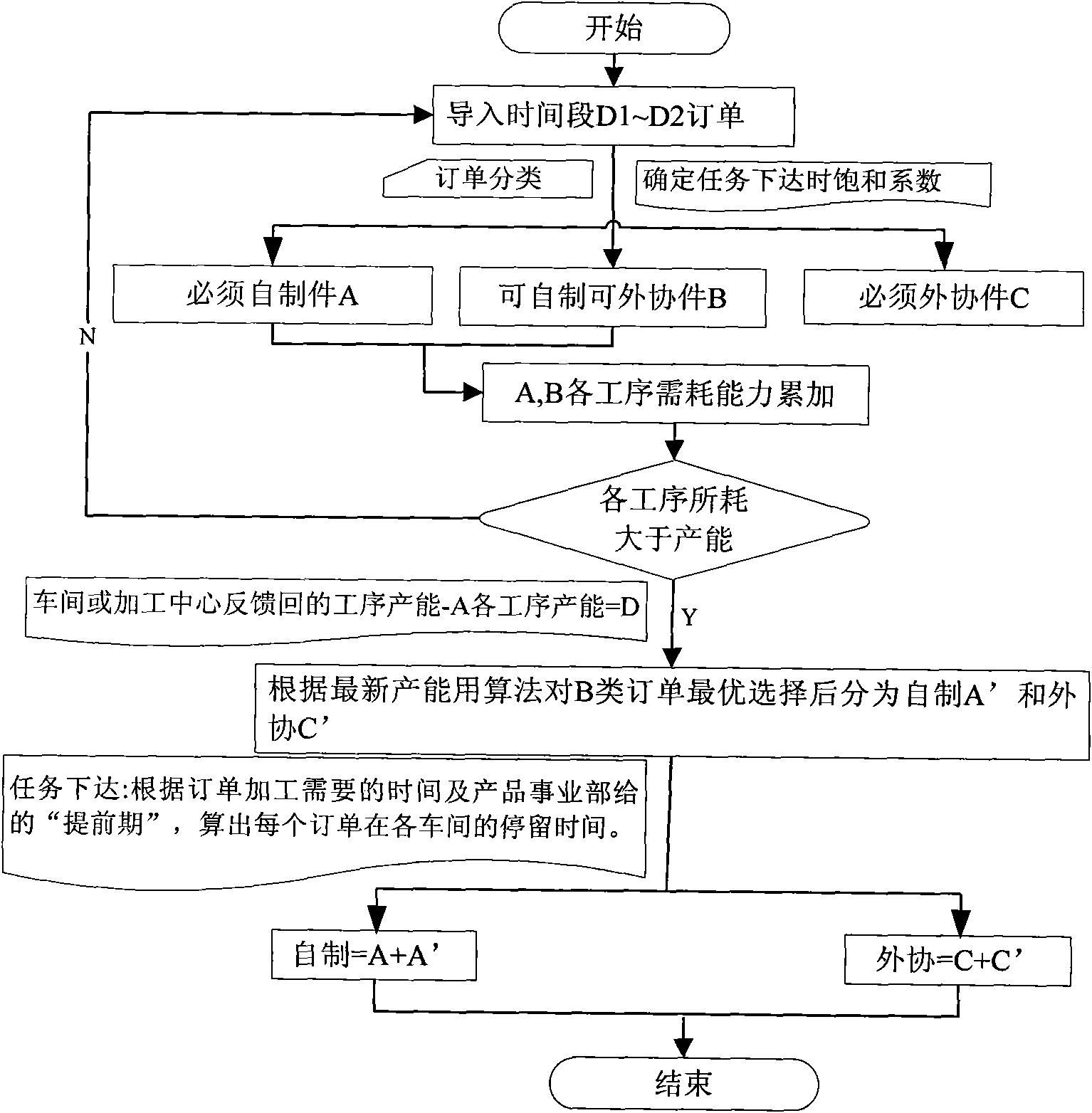

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

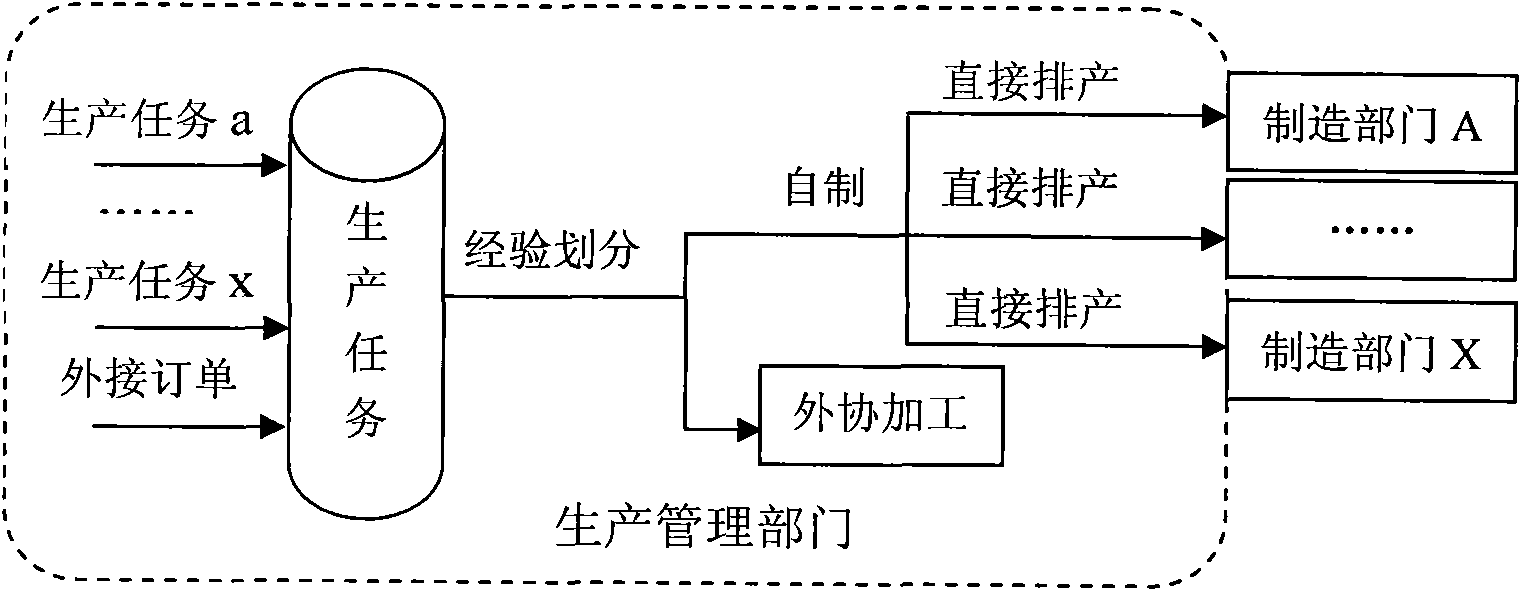

[0021] The present invention establishes a model method for the production management department to carry out scientific self-control and outsourced distribution of production tasks, establishes a scientific residence time decomposition model method for processing orders in each operation area, and establishes production scheduling rules in line with actual production, thereby optimizing production Organize the process and improve the efficiency of the entire production control.

[0022] The specific implementation of this method is as follows:

[0023] (1) Optimization of production order release mode (process)

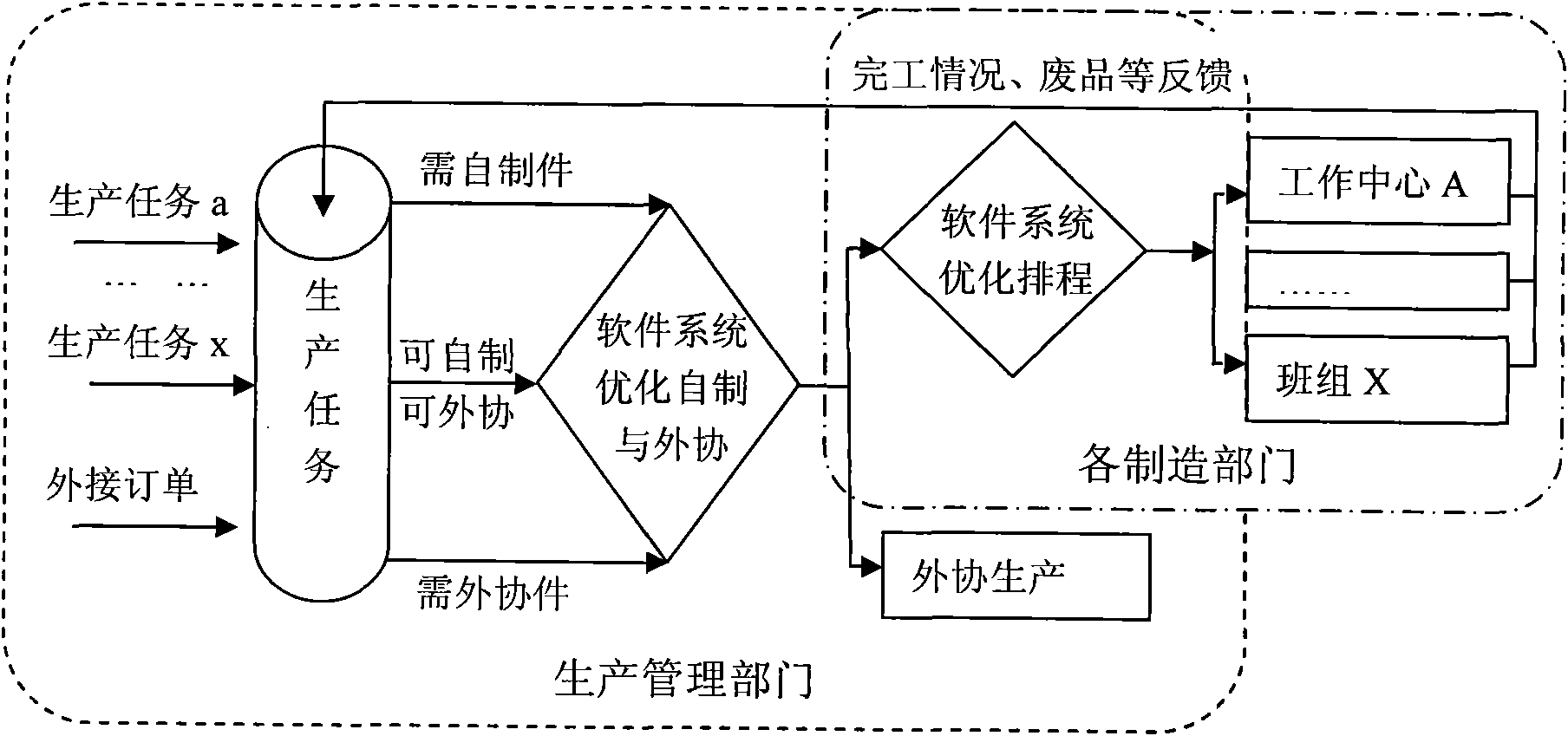

[0024] The present invention proposes an improved production order release mode, such as figure 2 Shown:

[0025] In the improved order placing mode of the present invention, after the production managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com