Hollow filled plastic-steel building template and composite structure

A technology for building templates and combined structures, which is applied in the direction of building construction, formwork/formwork components, and on-site preparation of building components. It can solve the problems of less running times, waste of wood, and high cost, and achieve fast assembly and disassembly. , Improve work efficiency, easy to manufacture and implement the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

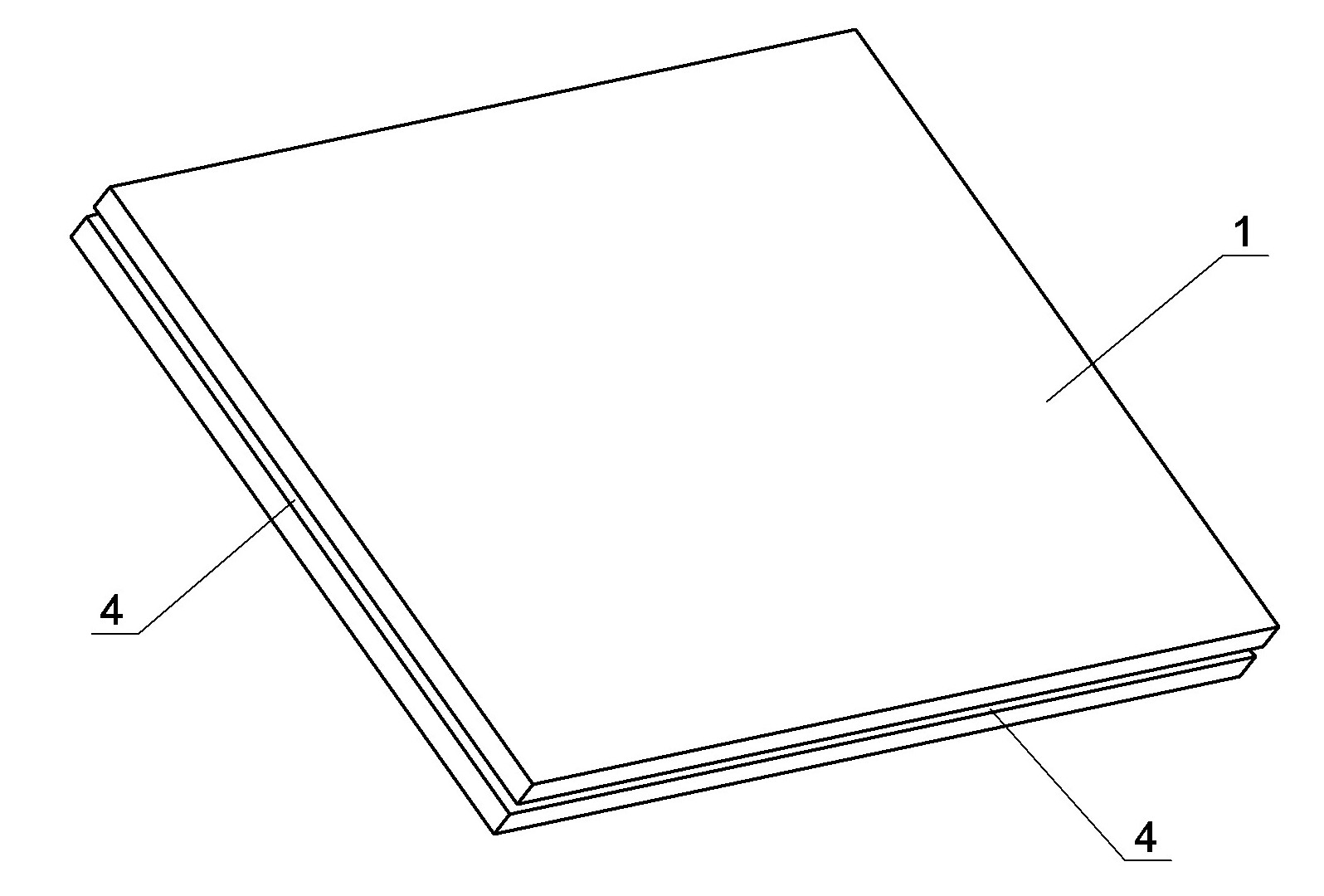

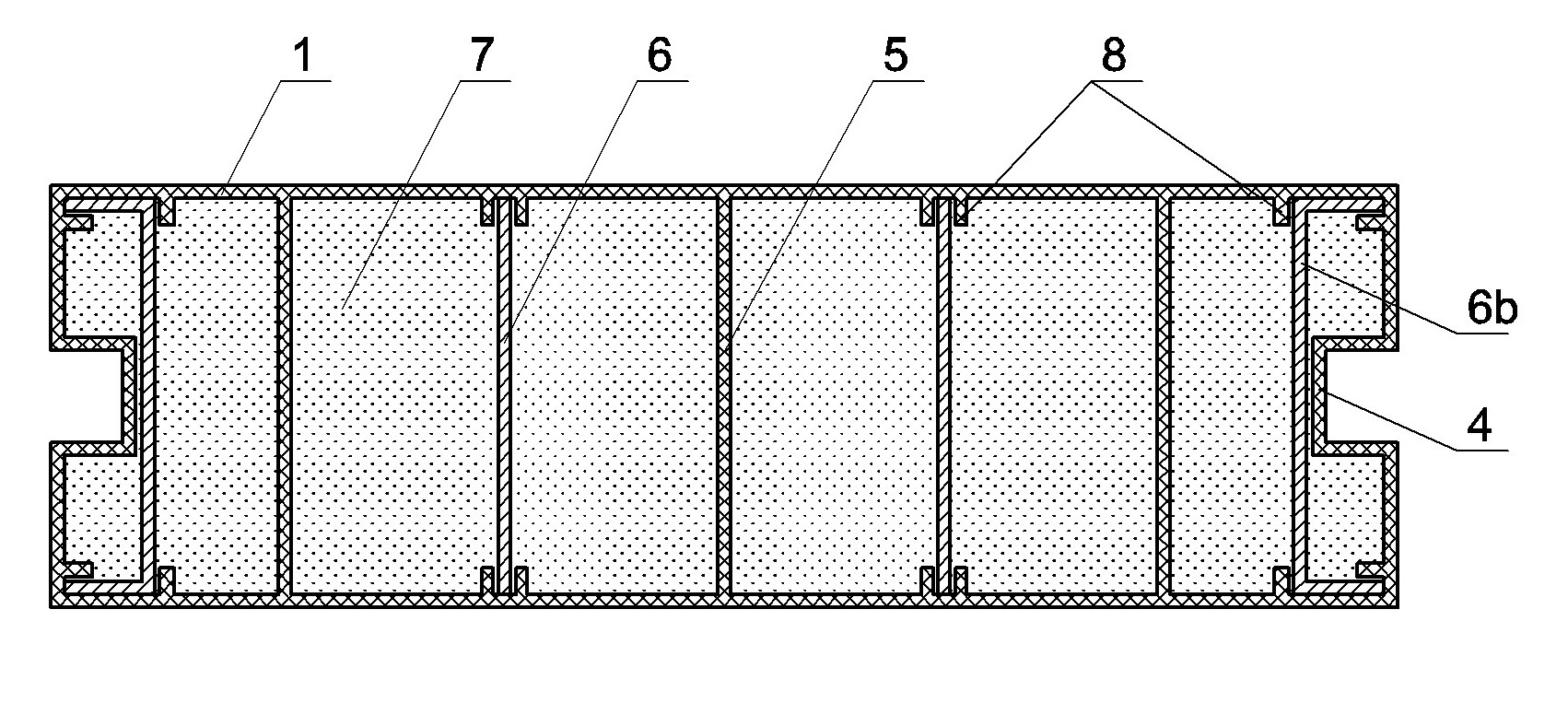

[0048] Embodiment one: see figure 1 , image 3 , a hollow filled plastic-steel building formwork, including a plane formwork surrounded by two parallel panels and surrounding side panels, the inner cavity of the plane formwork is fixed and connected longitudinally with stiffeners 5 perpendicular to the panels, and the stiffeners are connected at the same time The parallel panels on both sides play a certain supporting role, and the above-mentioned plane formwork and the stiffeners therein are all made of engineering plastics. At symmetrical positions between the two parallel panels, longitudinal grooves surrounded by double flanges 8 are respectively provided, and a hard support plate 6 is inserted and fixed between the two longitudinal grooves. The strip structure with a rectangular cross-section is made of a steel plate with a higher hardness coefficient than the plastic formwork, or a bamboo board, or a wooden board, or other hard material boards. The hard support boards a...

Embodiment 2

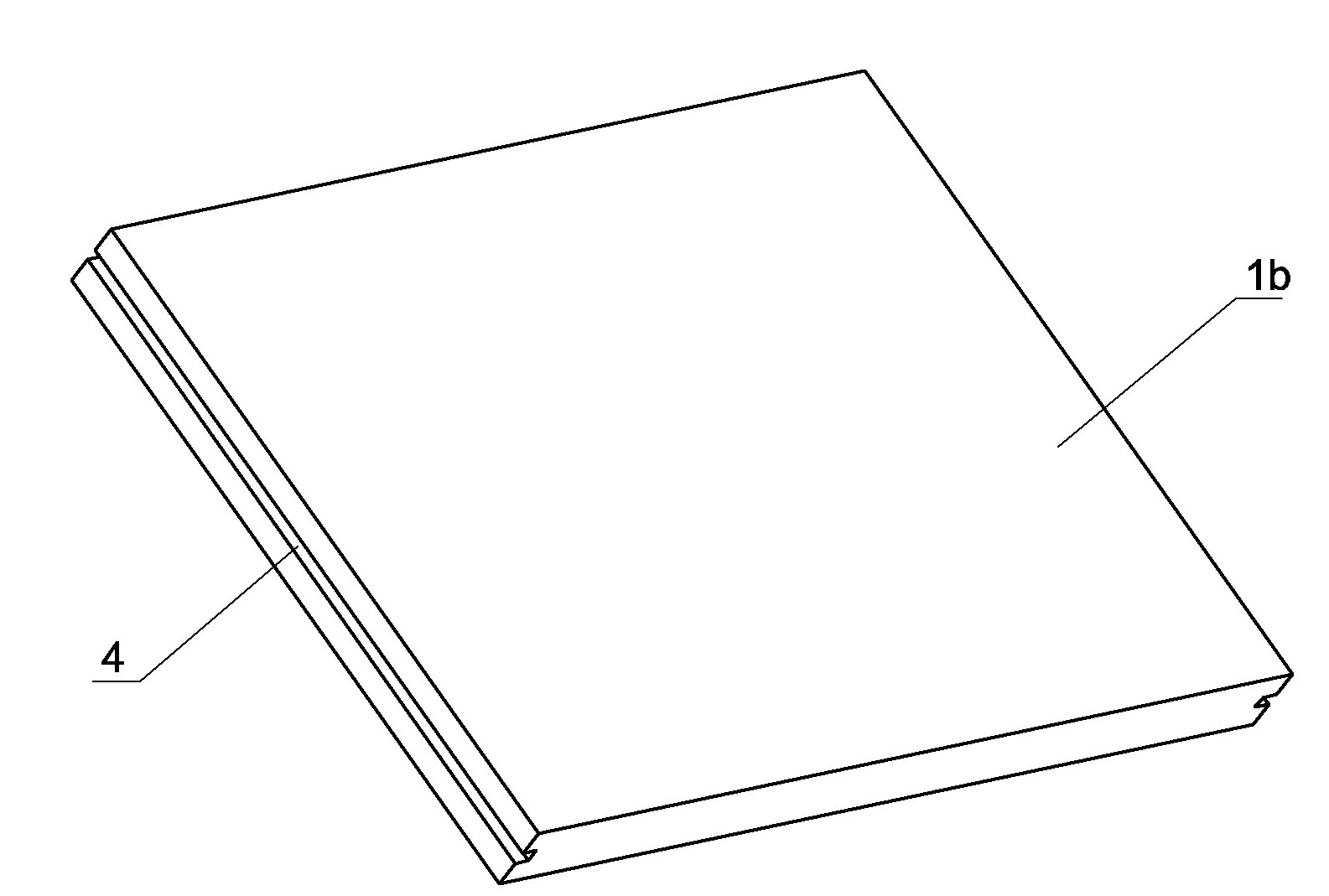

[0054] Embodiment two: see figure 2 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the middle parts of the two sides are respectively provided with hollow filled plastic-steel building templates with grooves 4 .

Embodiment 3

[0055] Embodiment 3: The picture is not drawn, and the content is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is: the middle parts of the three sides are respectively provided with hollow filled plastic-steel building templates with grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com