Guide beam type bridge-erecting machine capable of performing variable-span erection

A bridge erecting machine and guide beam type technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of poor adaptability, large cross-sectional size of the bridge erecting machine, and inability to change the span of box girder construction, etc. It is easy to achieve. The effect of realization and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

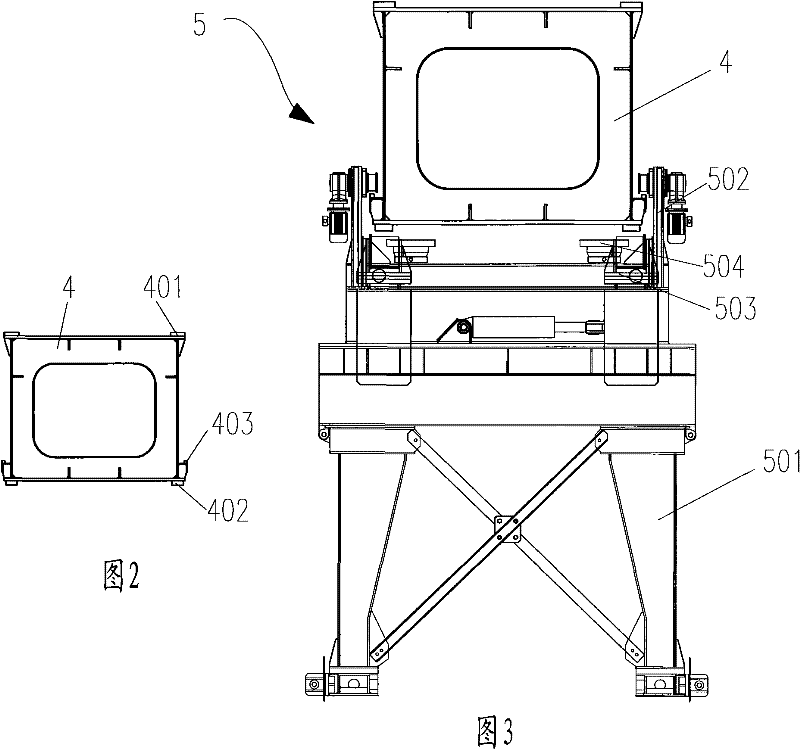

[0028] See attached figure 1 The shown guide girder bridge erecting machine includes a main girder 1, a main girder front leg 2 installed at the front end of the main girder 1, a main girder rear leg 3 installed at the rear end of the main girder, and a The lower guide beam 4, the lower guide beam front leg 5 installed at the front end of the lower guide beam, the lower guide beam alignment leg 6 installed at the lower guide beam rear end, the movable leg 7 movably arranged on the lower guide beam 4, Crane 8 and spreader 9 are also movable on the main girder 1 . The movable outrigger 7 is a structure that can be stretched up and down. It can be used as a fulcrum supported by the lower guide beam 4 on the bridge surface. a fulcrum.

[0029] Such as Figure 7 As shown, the main girder 1 is in the form of a double-girder box, and each set of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com