Metal elbow cold extrusion molding device

A forming device and cold extrusion technology, applied in the direction of metal extrusion die, metal extrusion mandrel, etc., can solve the problems of low bending cost, short process time, loss of filler, etc., achieve less bending time, simple operation, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

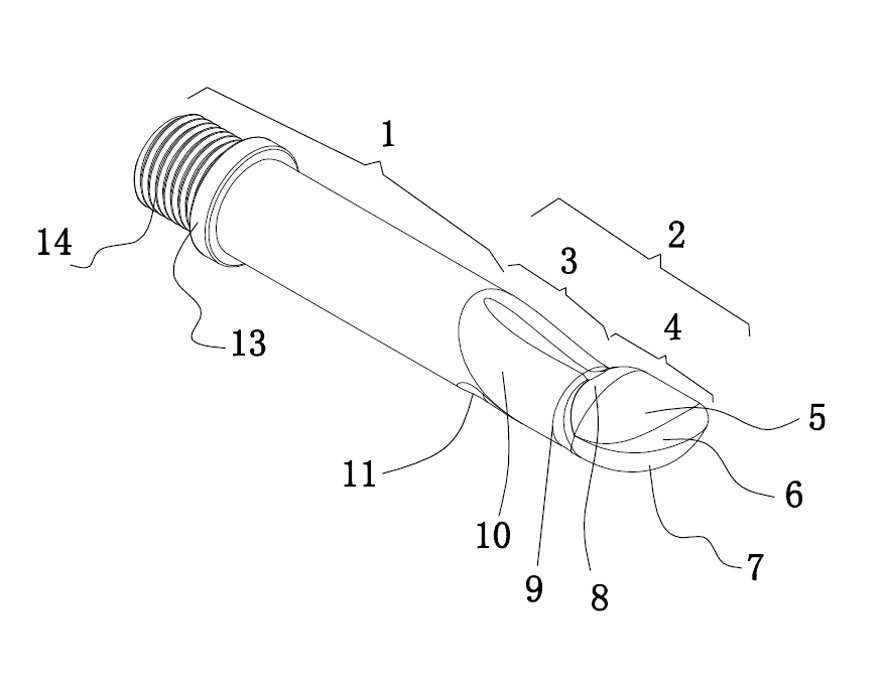

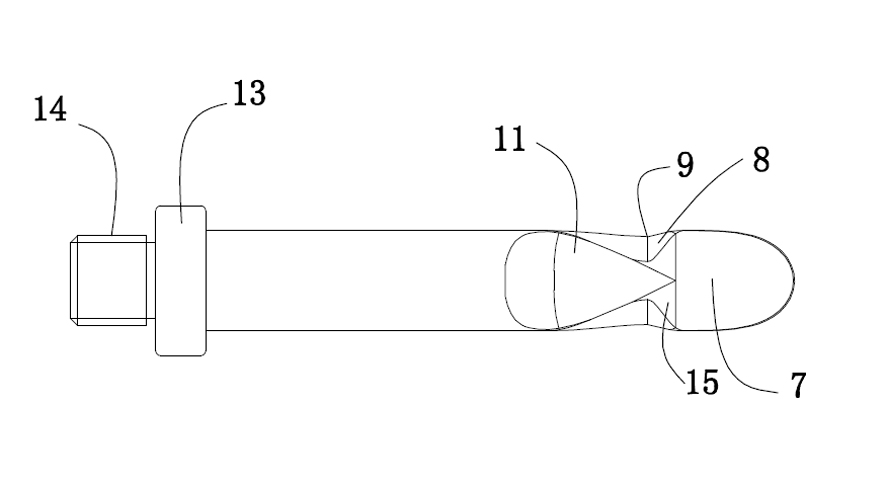

[0027] Embodiment: a kind of metal elbow cold extrusion molding device (see attached figure 1 ), including a forming mold composed of two templates 17. The mold is provided with a mold cavity 19 matching the shape of the finished elbow, and an extrusion core 16 and a push mandrel 18 are inserted into the cavity 19.

[0028] The extrusion core consists of a base shaft 1 and a working end 2 (see attached figure 2 attached image 3 Figure 4 ), the extrusion core is cylindrical as a whole, the working end 2 is an eccentric structure, the tail end of the base shaft 1 is provided with a boss 13, the outside of the boss 13 is a threaded end 14, and the threaded end 14 and the boss 13 are provided with Undercut groove, the working end 2 is divided into a transition part 3 connected with the base axis and an introduction part 4 connecting the end part and the transition part through a turning surface 9, the working end 2 is surrounded by a multi-curved surface, and the working end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com