Reel for band plate, band plate feed device with reel, and band plate feed method

A technology of supplying device and strip plate, which is applied in the direction of electromechanical device, coil manufacturing, and motor-generator manufacturing, etc., can solve problems such as difficulty in rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

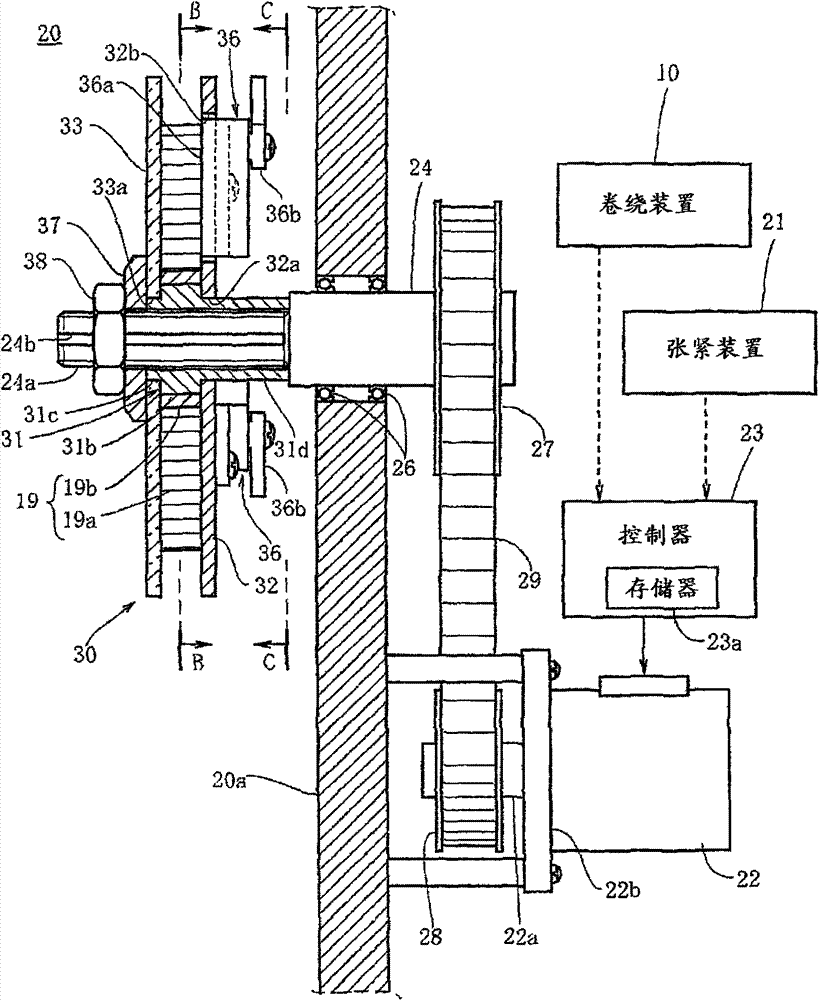

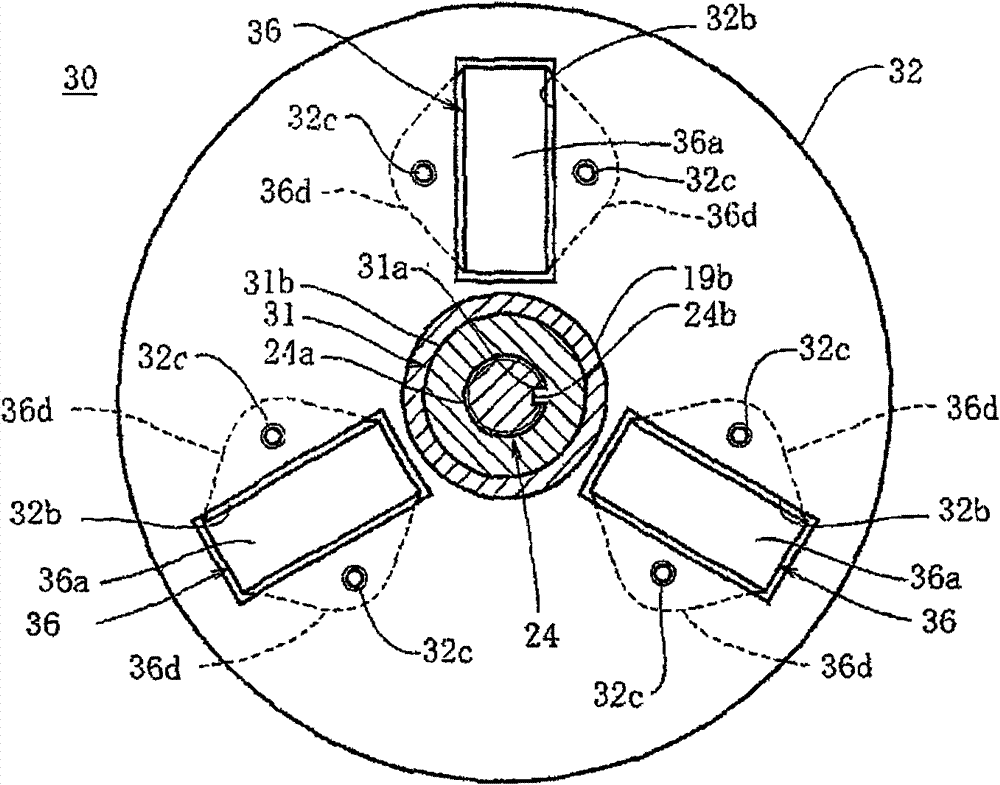

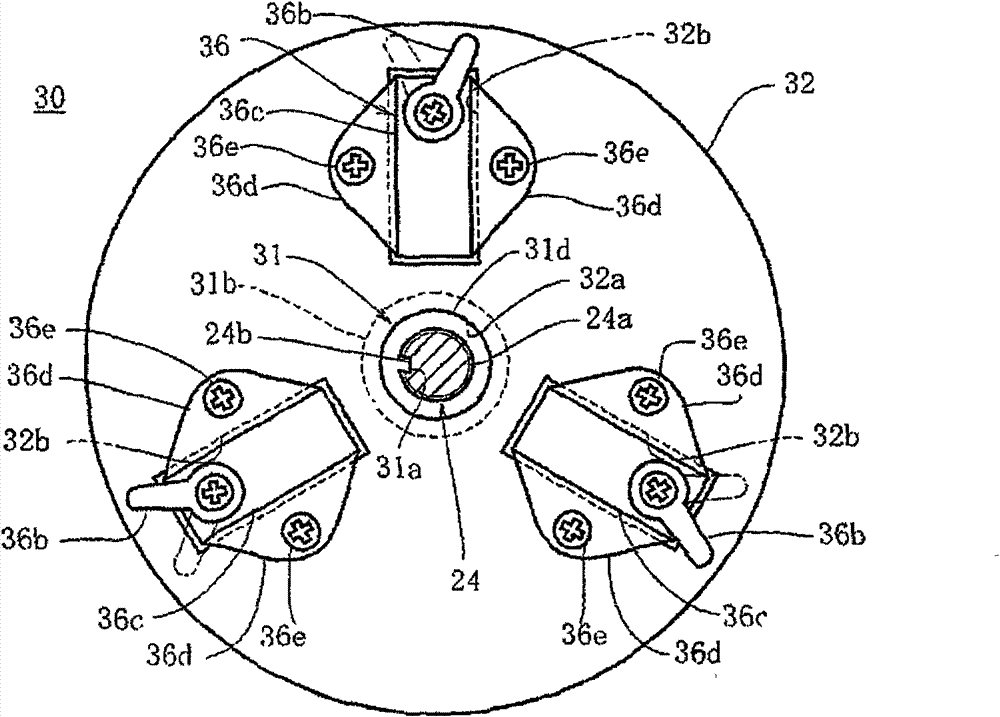

[0032] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings.

[0033] Such as Figure 5 As shown, the strip supply device 20 according to the invention has a reel 30 configured to hold a raw material 19 having a wound strip 19 a of magnetic material. The strip 19a wound on the reel 30 among the raw materials 19 is rotated in the direction indicated by the solid arrow, that is, the direction in which the strip 19a is rewound, from its outer periphery along the direction indicated by the dotted arrow. It is unwound radially outward and rewound, and then conveyed to a winding device 10 that winds the strip 19a to form a wound core.

[0034] Figure 5 The winding device 10 in has a winding core 13 provided so that its front end protrudes from the front of a main body 11 made of a rectangular body and is rotatable. The winding core 13 is rotationally driven by a drive mechanism not shown, and the strip plate 19 a is wound arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com