Light-guiding plate made by using offset printing method and making method thereof

An offset printing and light guide plate technology, applied in the field of light transmission devices, can solve the problems of little change in shape, monotony and no change, and achieve the effect of strong three-dimensional effect, vivid and beautiful appearance, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

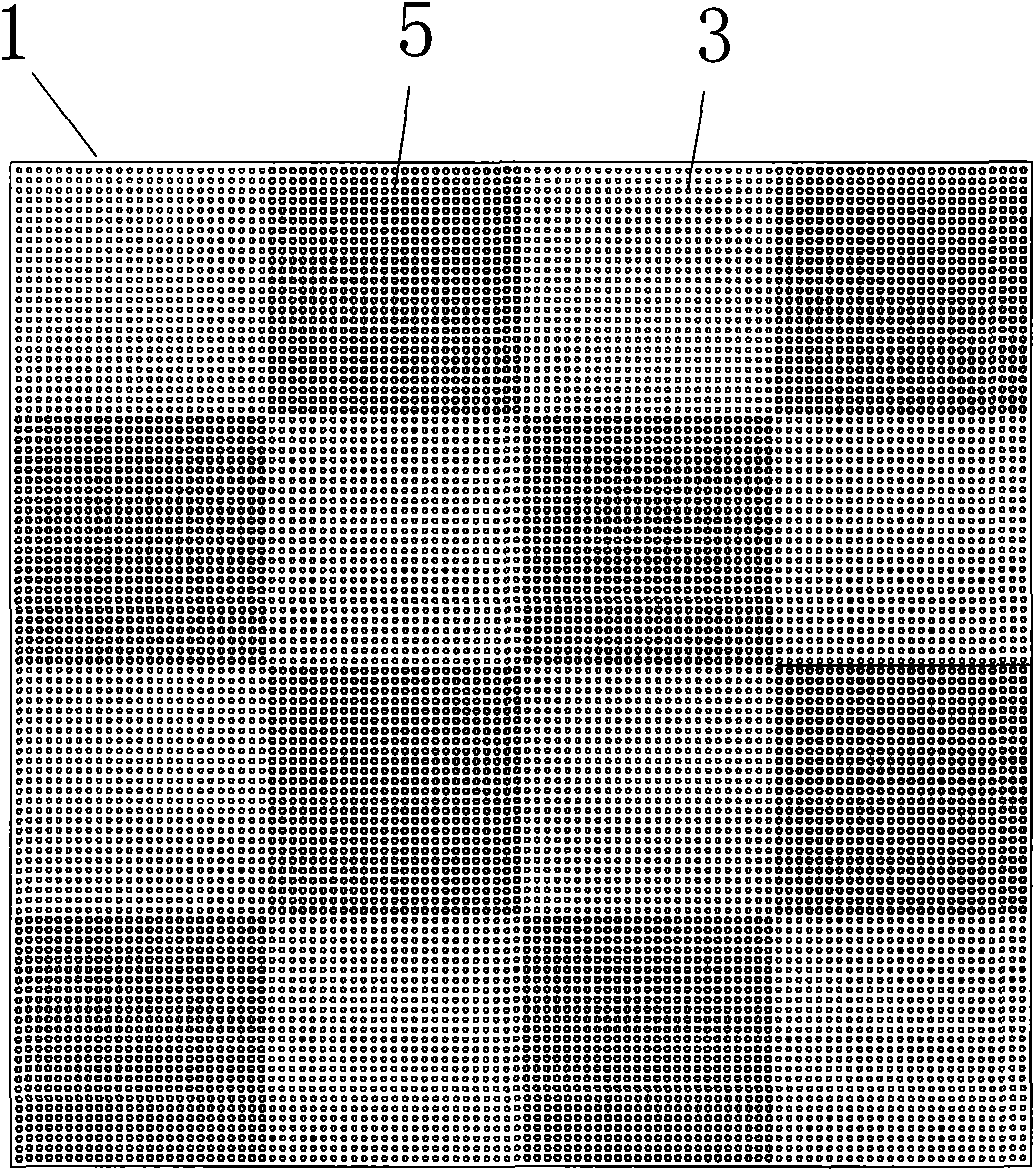

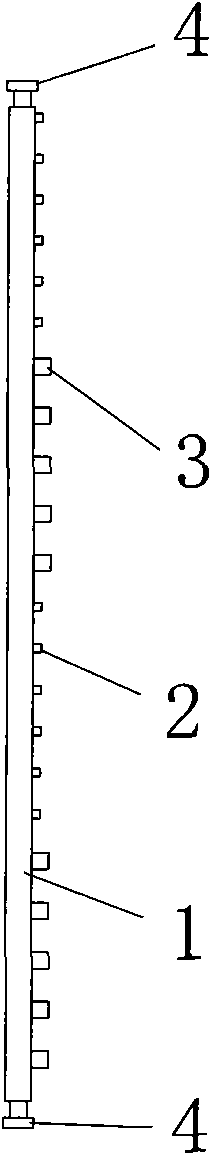

[0019] Figure 1a , Figure 1b The basic structure of the first embodiment of the present invention is shown. The light guide plate manufactured by offset printing includes a light guide plate 1 and light sources 4 arranged on both sides of the light guide plate. One side of the light guide plate is provided with light guide dots of different shapes, sizes or density distributions by means of offset printing. In this embodiment, the larger cylindrical light guide dots 3 and the smaller rectangular light guide dots 2 form grid patterns with different shades. Light guide points can be in any shape, such as circular, straight, cross and star. These light guide dots 2 and 3 with different shapes, sizes or density distributions are combined to form various graphics and texts. Graphics and texts can be any one of Chinese characters, letters or patterns, or any combination of Chinese characters, patterns, and letters.

[0020] Figure 2a , Figure 2b The basic structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com