Method and device for calibrating top plate dynamic apparatus

A calibration device and calibration method technology, applied in transmission devices, measuring devices, mechanical devices, etc., can solve the problems of calibration based on measurement performance without traceability of value, measurement performance is not determined, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

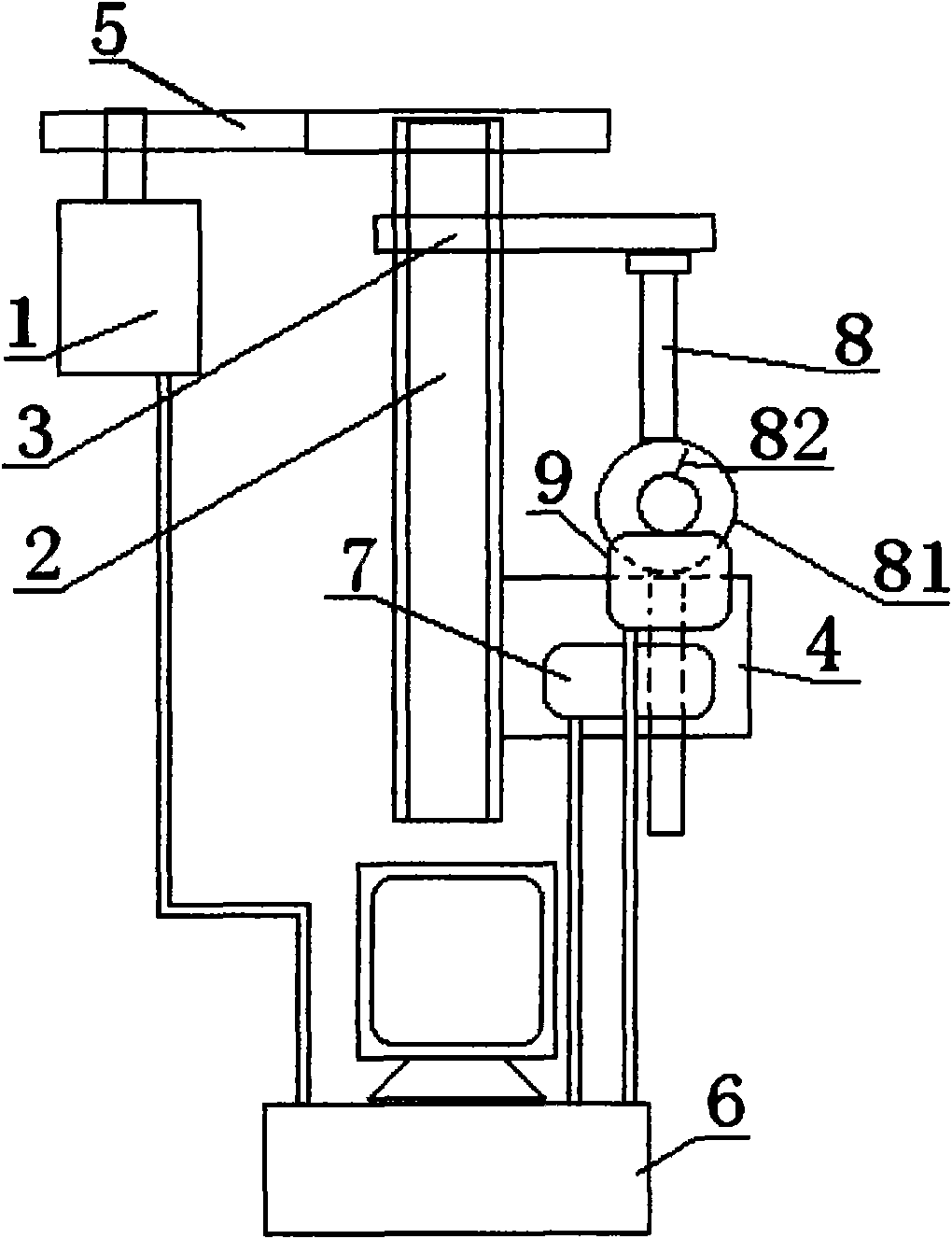

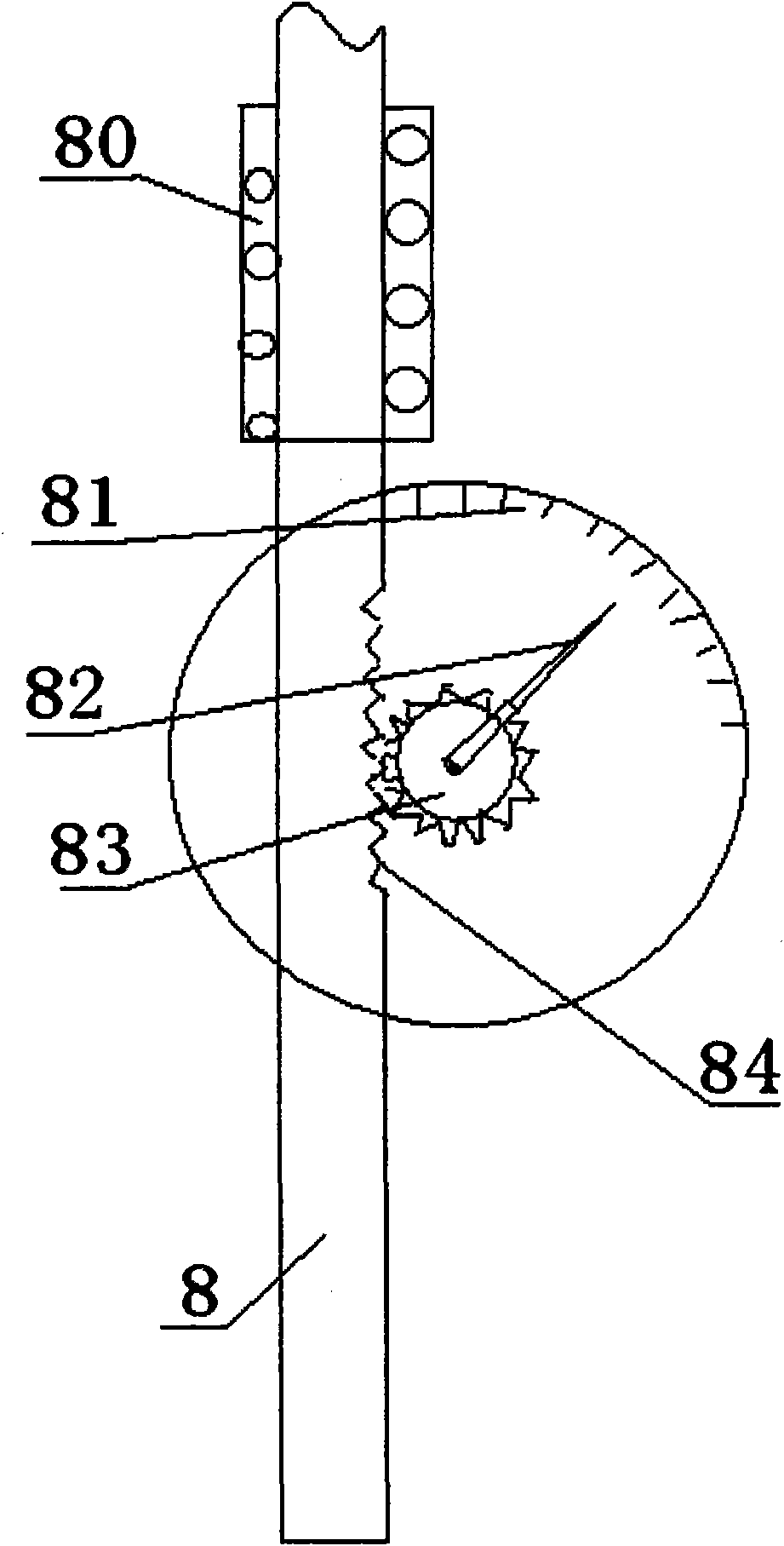

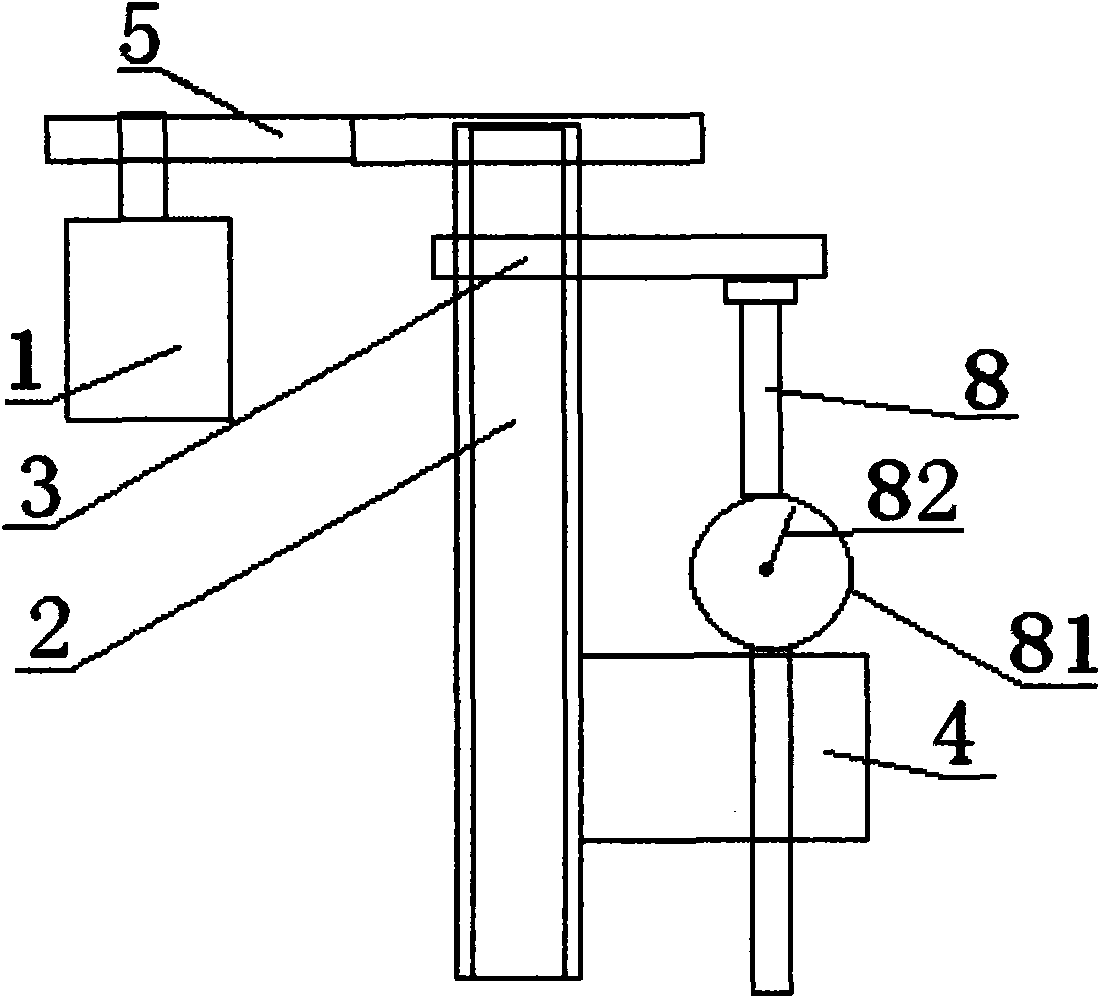

[0080] Such as figure 1 with 3 As shown in -4, the roof dynamic instrument calibration method of the present invention is to use the stepping motor 1 controlled by the PC 6 to drive the precision lead screw 2 through the timing belt transmission mechanism 5, and the precision lead screw 2 drives the inner threaded button type slider that it is equipped with. The block-type measuring indenter 3 performs precision stroke calibration of the top plate dynamic instrument clamped in the rigid fixture 4 of the top plate dynamic instrument whose jaws are parallel to the measurement axis, and the running track is parallel to the measurement axis.

[0081] The PC is equipped with special control and detection software through the stepper motor control card installed on its main board and its hard disk, and controls the stepper motor through the stepper motor driver board; When the precision lead screw 2 is driven forward, it also slides along the sliding track parallel to the measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com