Planetary shaft difference adjusting differential mechanism

A differential and planetary shaft technology, applied in the field of vehicle differentials, can solve problems such as instability, serpentine forward turning radius, poor controllability of wheelchair motion, etc., and achieve the effect of precise steering and smooth linear motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

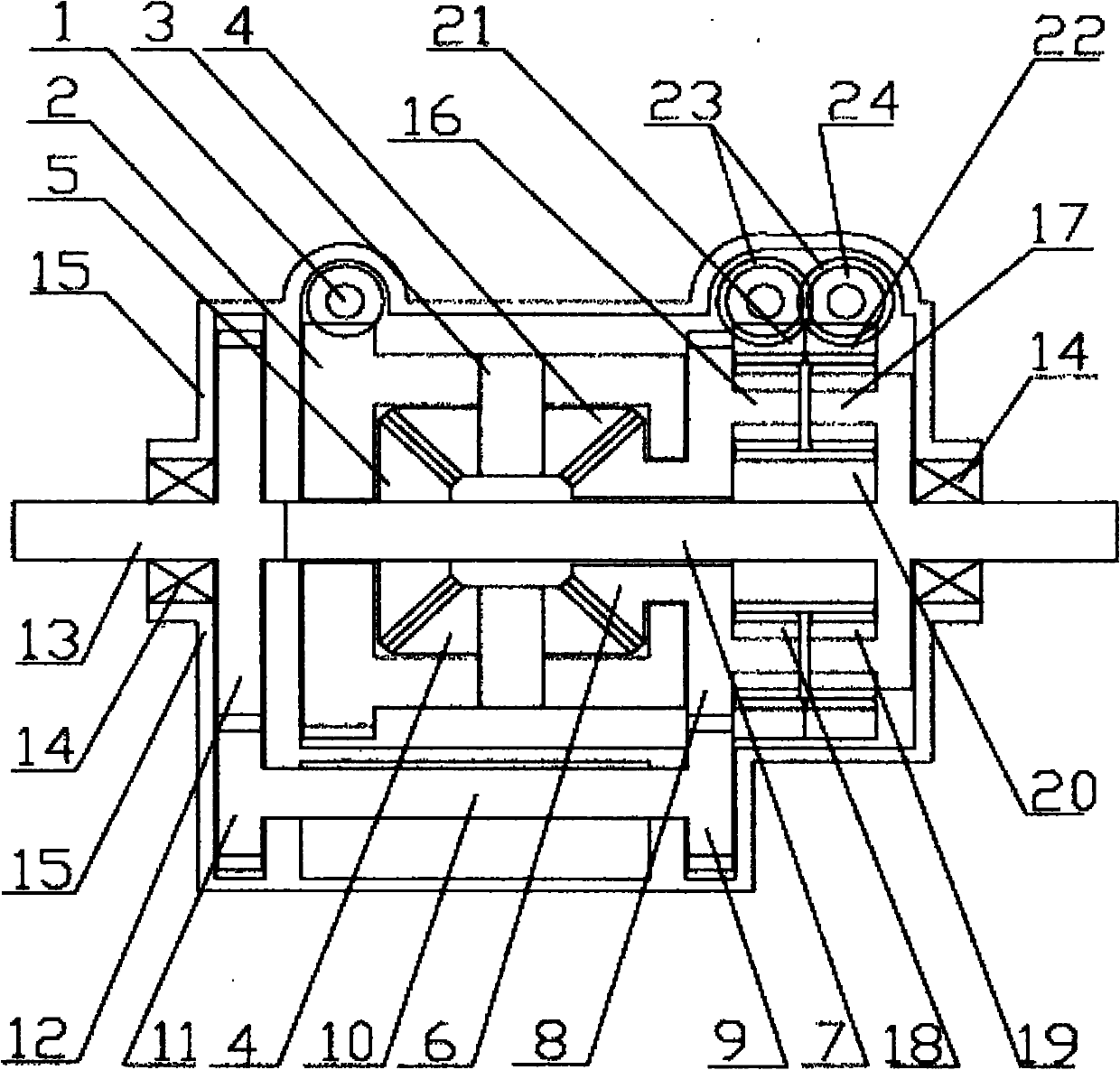

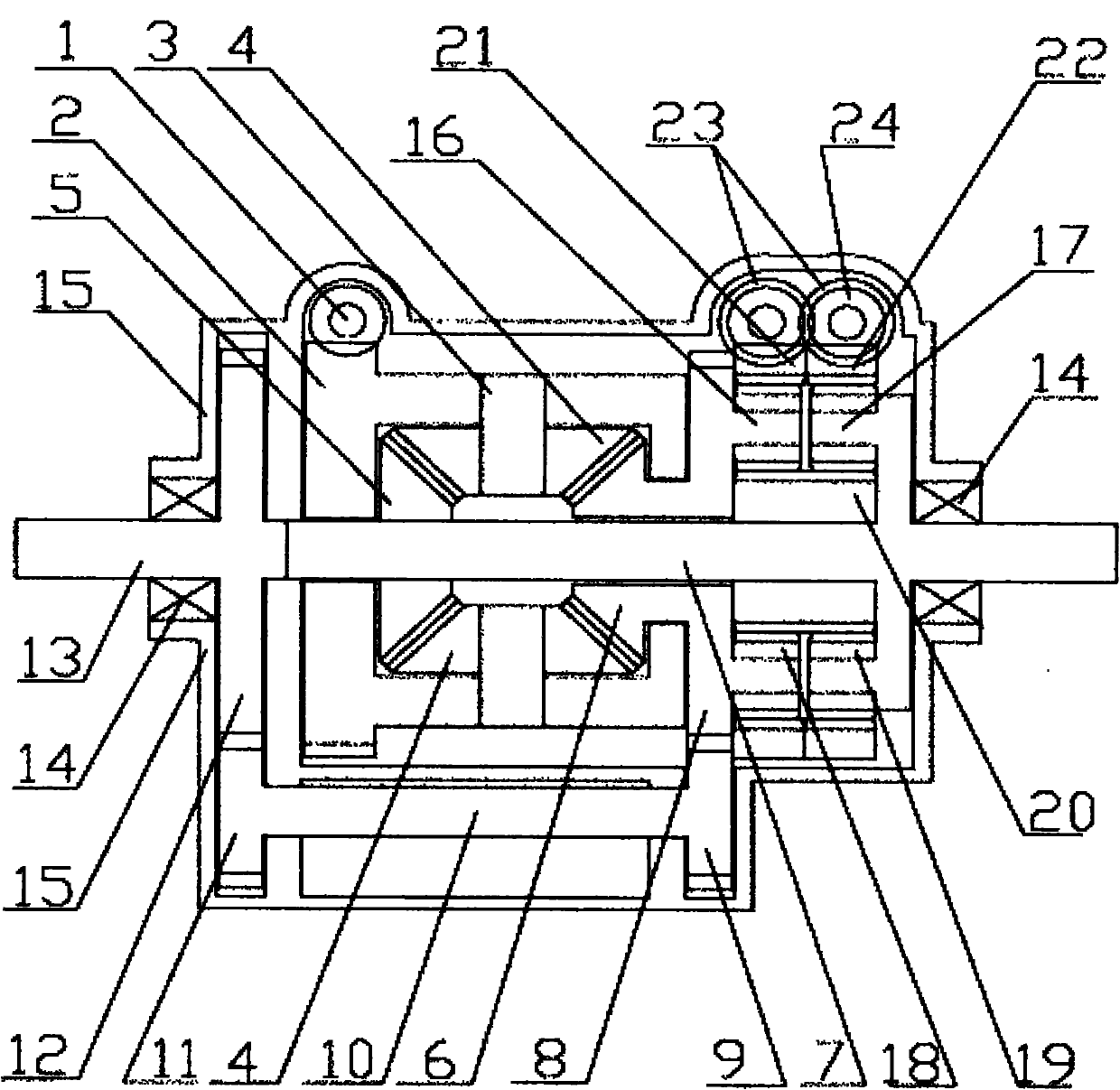

[0007] Referring to the accompanying drawings, the present invention is characterized in that the planetary shaft differential differential is to input the two output degrees of freedom of the differential to two sets of mutually locked planetary gear sets through the planetary gear carrier, and then control the two planetary gears The group realizes the adjustment of the rotational speed difference between the two outputs, and uses the constant speed drive shaft and the worm 1 to directly drive the constant speed drive worm gear 2. The constant speed drive worm gear 2 and the differential gear frame 3 are integrated; the differential planetary gear 4, The right half shaft bevel gear 5 and the left half shaft bevel gear 6 are installed in the differential gear frame 3 to form a differential; the left half shaft bevel gear 6 and the left half shaft first transmission gear 8 and the planets carried by the left half shaft The gear bracket 16 is coaxial, the first transmission gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com