Elastic-plastic steel-structured safety protection device

A safety protection device and elasto-plastic technology, applied in the field of safety protection device and elastic-plastic steel structure safety protection device, can solve the problems of dissipating impact energy, etc., and achieve dissipating impact energy, uniform force, and increase force range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

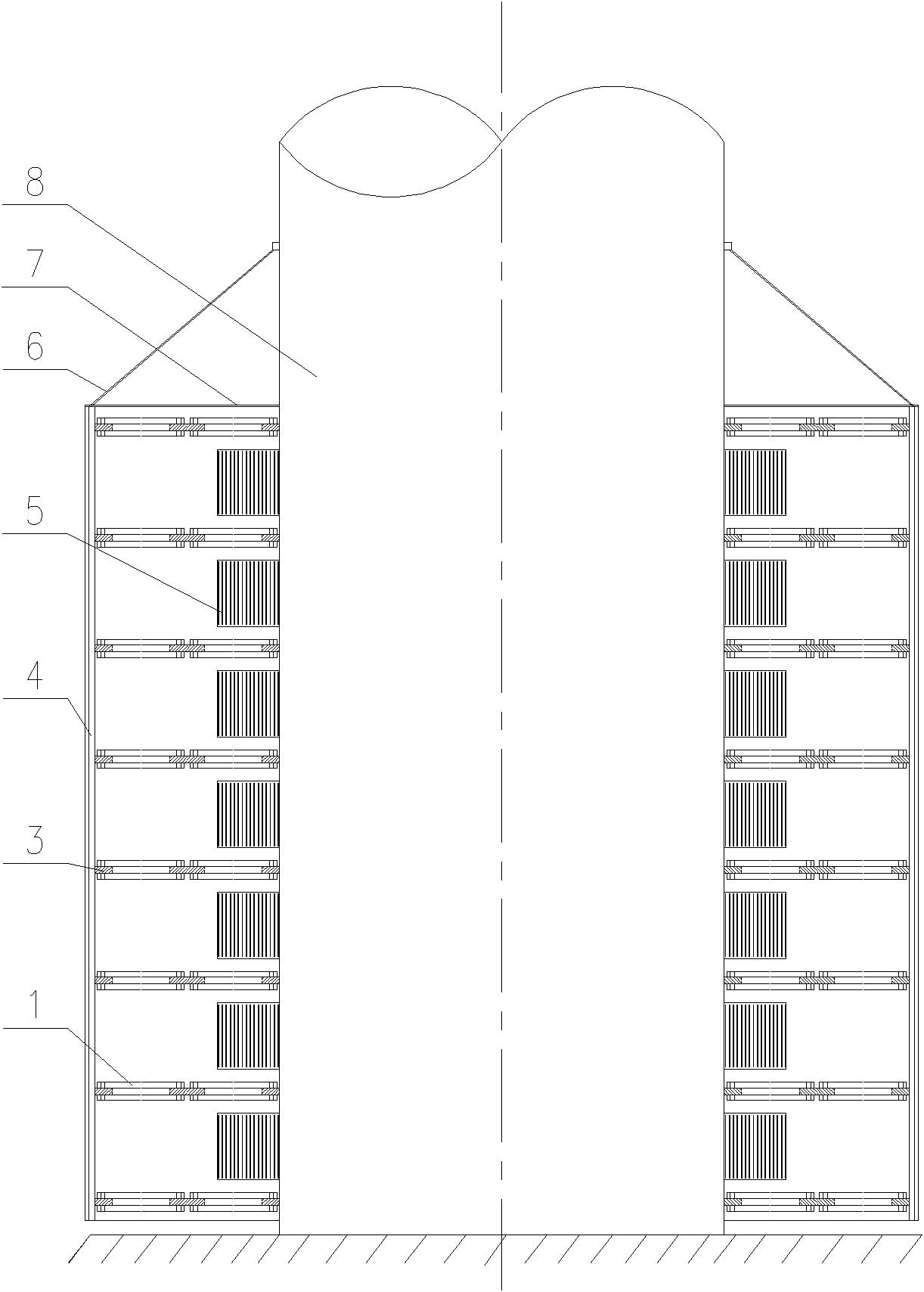

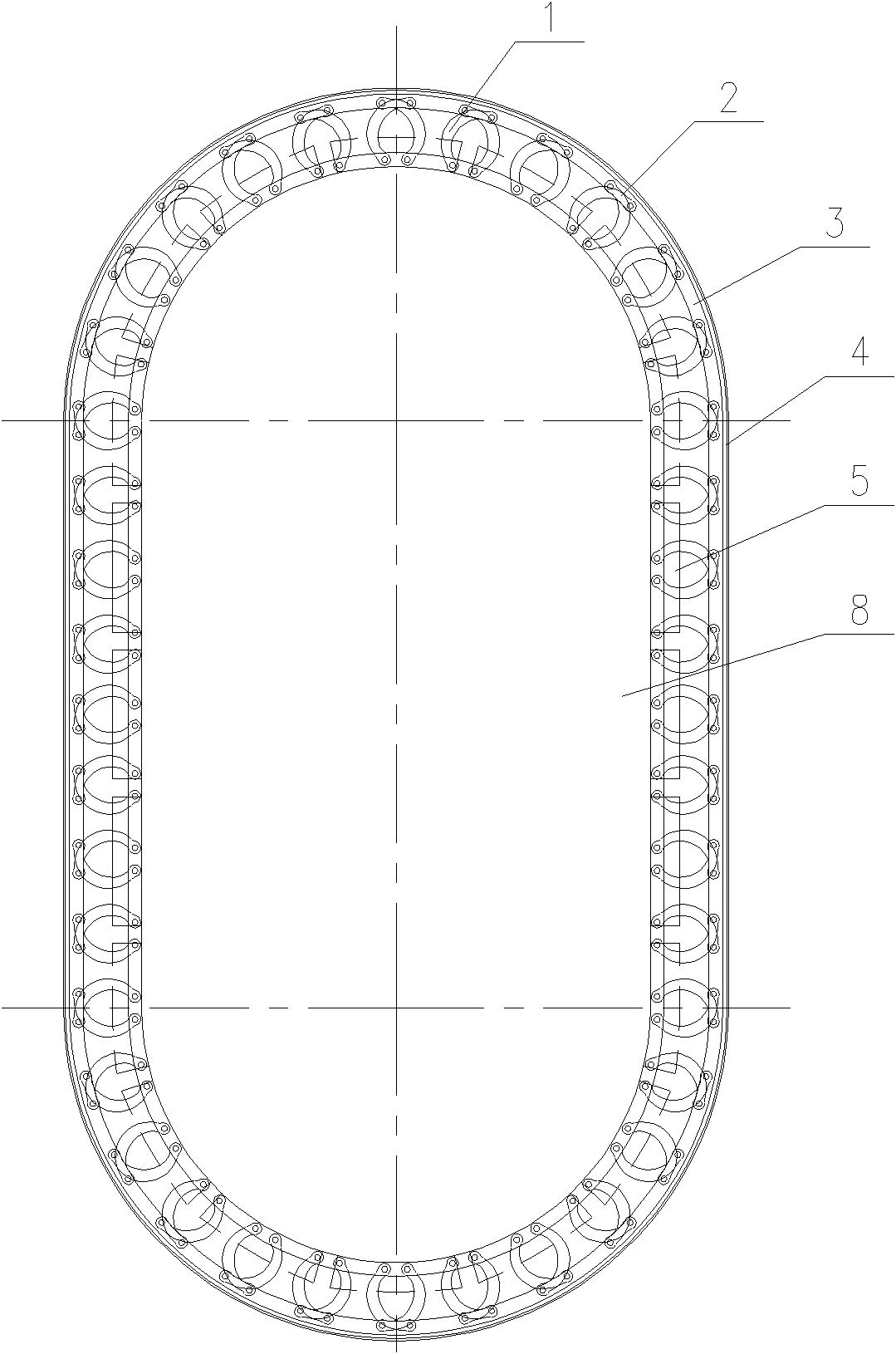

[0024] Example 1 as figure 2 , image 3 As shown, eight layers of buffer components are vertically arranged in the protective outer layer 4 of this embodiment to surround the pier 8. The horizontal section of the protective outer layer 4 is circular, and each layer of buffer components includes two layers of stiffening beams 3 with horizontal rings. The beam 3 is also correspondingly annular. The buffer members 2 are evenly distributed on the upper and lower sides of the stiffening beams 3 on the two layers. In the vertical direction, the adjacent buffer members 2 are arranged alternately. The horizontal inner stiffening beam 3 is connected, the inner stiffening beam 3 is tightly hugged to the pier 8, and the shock-absorbing rubber block 5 is connected to the upper and lower adjacent inner stiffening beams 3 and riveted with the pier 8, and each layer The stiffening beams 3 of the horizontal outer layer of the buffer assembly are all fixed on the inner wall of the protectiv...

Embodiment 2

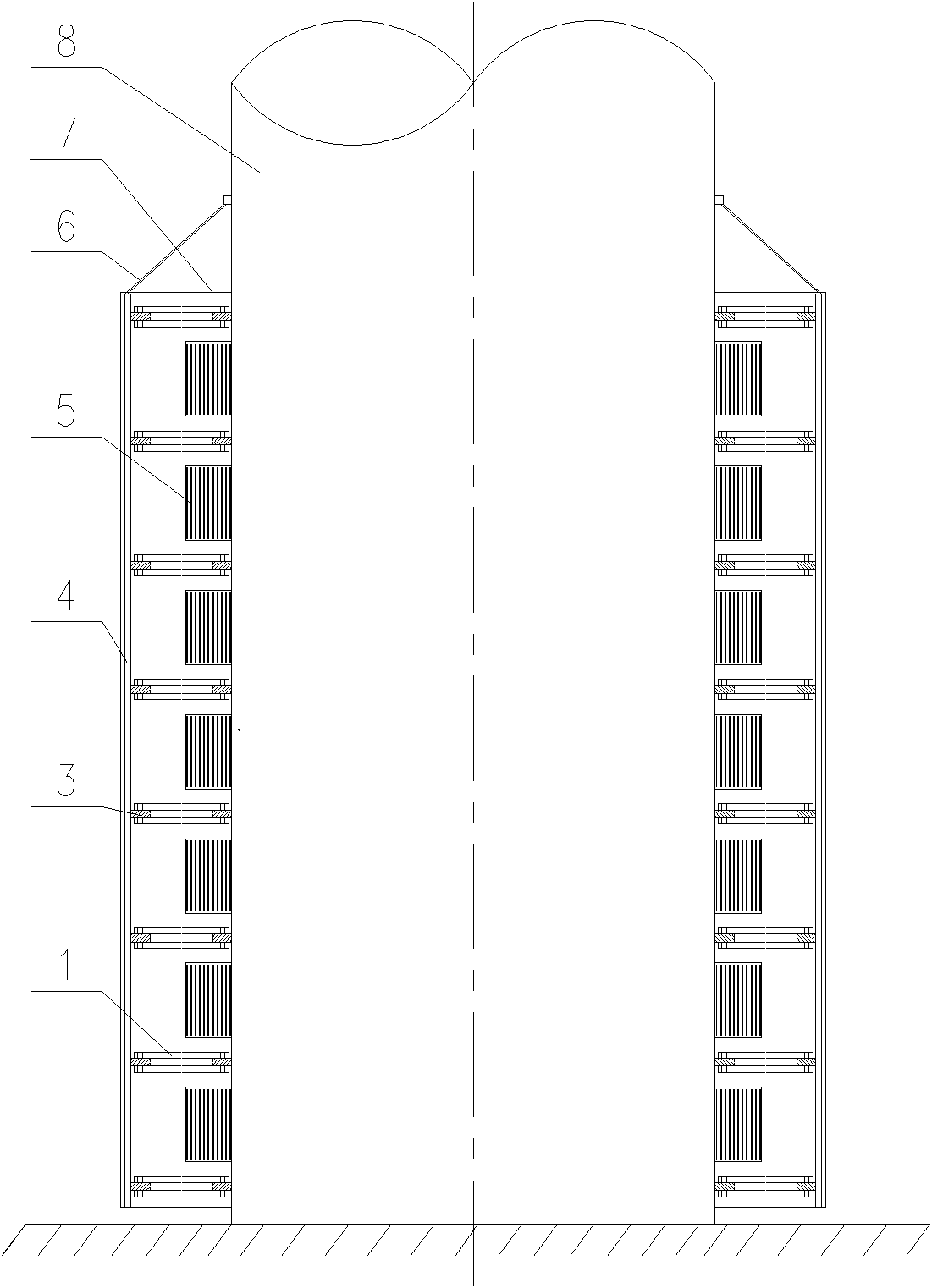

[0027] Example 2 as Figure 5 , Image 6 As shown, eight groups of buffer assemblies are arranged vertically up and down in the protective outer layer 4 of this embodiment. The horizontal section of the protective outer layer 4 is circular, and the stiffening beam 3 is also a corresponding ring shape. Each layer of buffer assemblies includes three layers of ring sleeves. Beam 3, the innermost stiffened beam 3 tightly hugs the pier 8, similar to the connection mode between the buffer member 2 and the stiffened beam 3 in Embodiment 1, the inner stiffened beam 3 and the middle stiffened beam 3 in this embodiment are buffered The members 2 are connected, and the stiffening beams 3 of the middle layer and the stiffening beams 3 of the outer layer are also connected sequentially through the buffer members 2, and the intersecting ends of the buffer members 2 are always in the outer layer; between the vertically adjacent stiffening beams 3 of the inner layer Connect the shock-absorbi...

Embodiment 3

[0028] Example 3 as Figure 8 , Figure 9 , Figure 10 As shown, the protection design is mainly designed for the structures in the intercommunication triangle area. Since the intercommunication triangle area is a diversion place for automobiles, it is easy to be hit by automobiles. Such as Figure 9 As shown, wherein the front-end protective column 9 is cylindrical, and the safety protection device arranged on it is half around the front end of the protective column 9 (that is, facing the direction in which the vehicle enters), and the protective outer layer 4 of the safety protection device is horizontally stacked. The surface is a semicircle, and each layer of buffer components in the protective outer layer 4 includes three layers of stiffening beams 3 arranged horizontally inside and outside, and the stiffening beams 3 are also corresponding semi-circular. The shock-absorbing rubber blocks 5 are connected between adjacent stiffening beams 3 , and the shock-absorbing rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com