Main runner structure of mould

A main channel and mold technology, applied in the field of injection mold structure, can solve the problems of waste of raw materials, increase of production cost, short service life of the mold, etc., and achieve the effect of no waste of raw materials, long service life and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

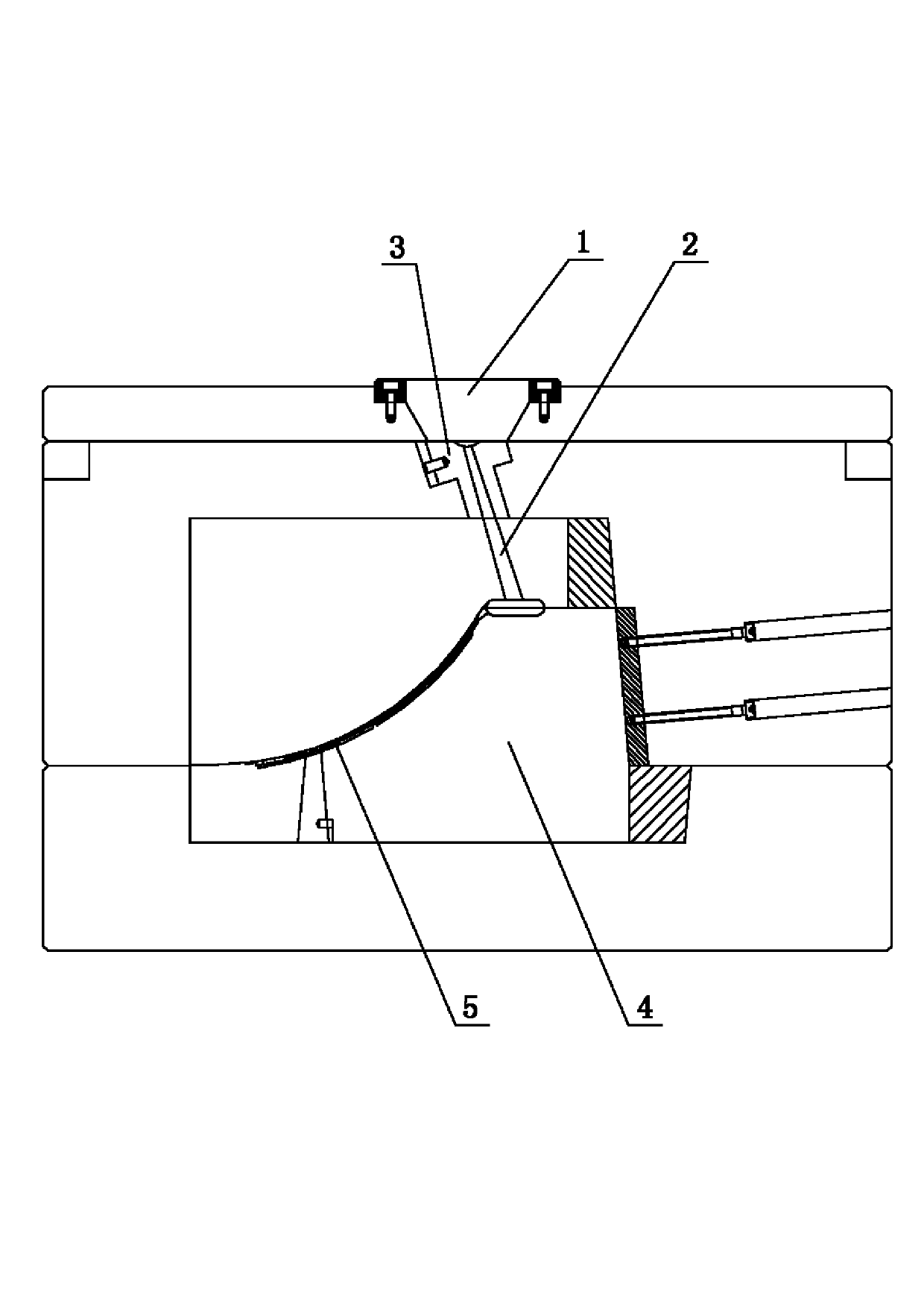

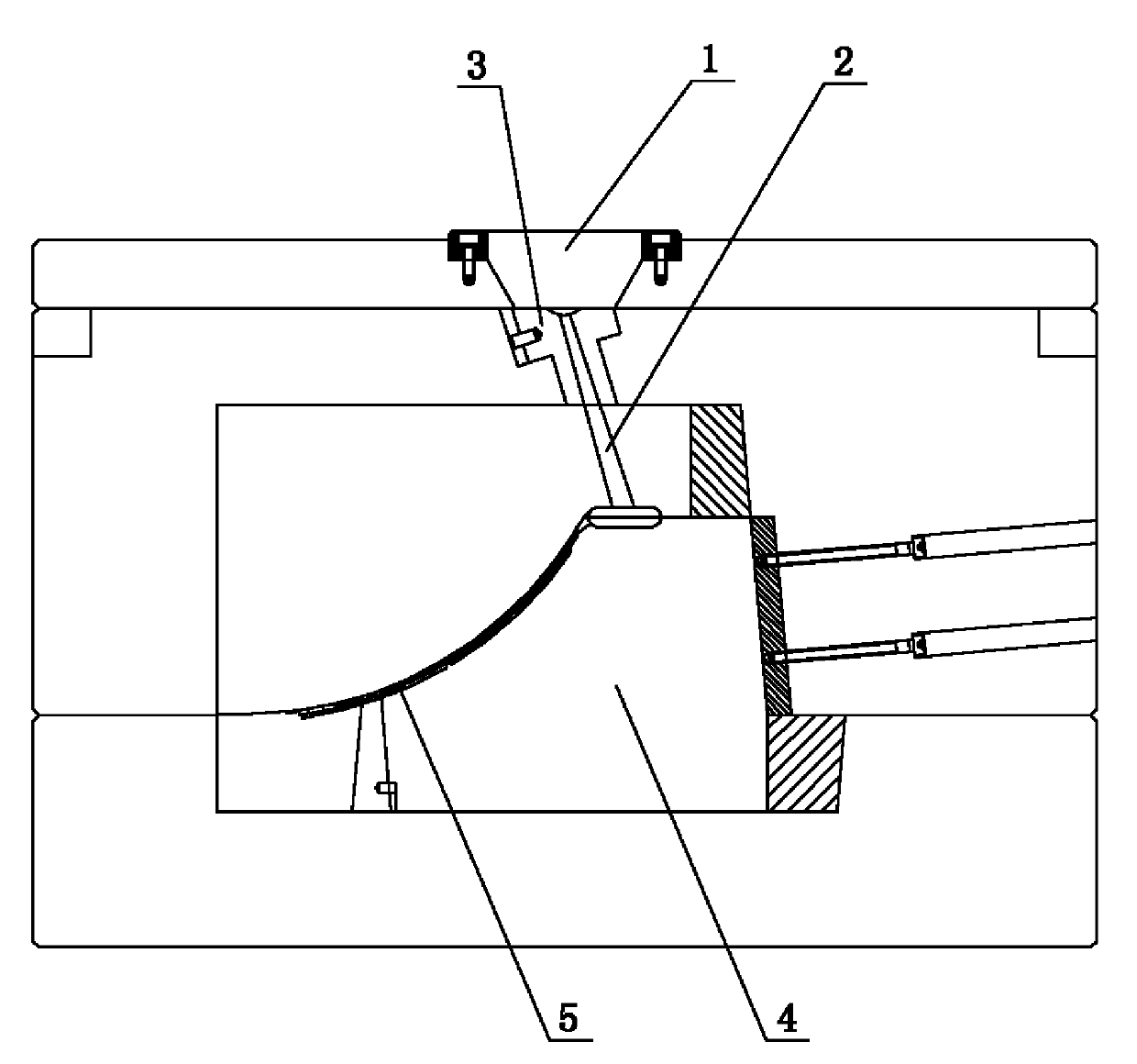

[0010] See figure 1 , the present invention includes injection molding machine nozzle 1, sprue 2, sprue sleeve 3, mold 4, mold cavity 5, nozzle 1 of injection molding machine is aligned with the top of sprue 2, sprue sleeve 3 is installed on the top of sprue 2 The outer edge, the bottom of the sprue 2 leads to the mold cavity 5, the sprue 2 is arranged obliquely, the outlet at the bottom of the sprue 2 is located in the center of the mold 4, the inner hole of the sprue sleeve 3 is arranged obliquely, and the inner hole of the sprue sleeve 3 The hole fits on the top outer edge of the sprue 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com