Water shutdown mechanism for instantaneous electric kettle

An electric kettle and instant heating technology, applied in water-boiling utensils, kitchen utensils, household utensils, etc., can solve the problems of affecting the stability of water output, poor operation flexibility, poor reliability, etc., and achieve enhanced operation comfort, Easy processing and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

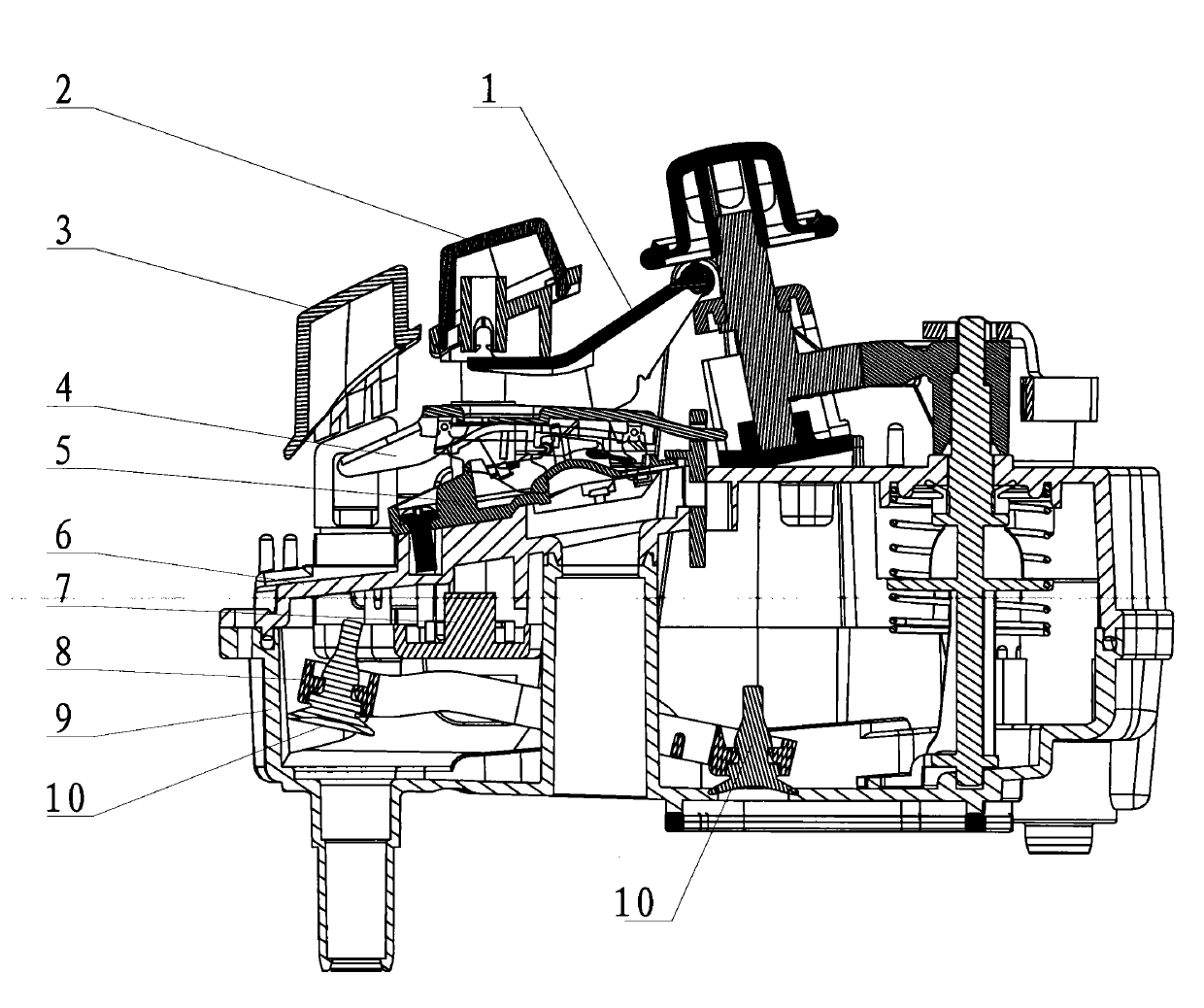

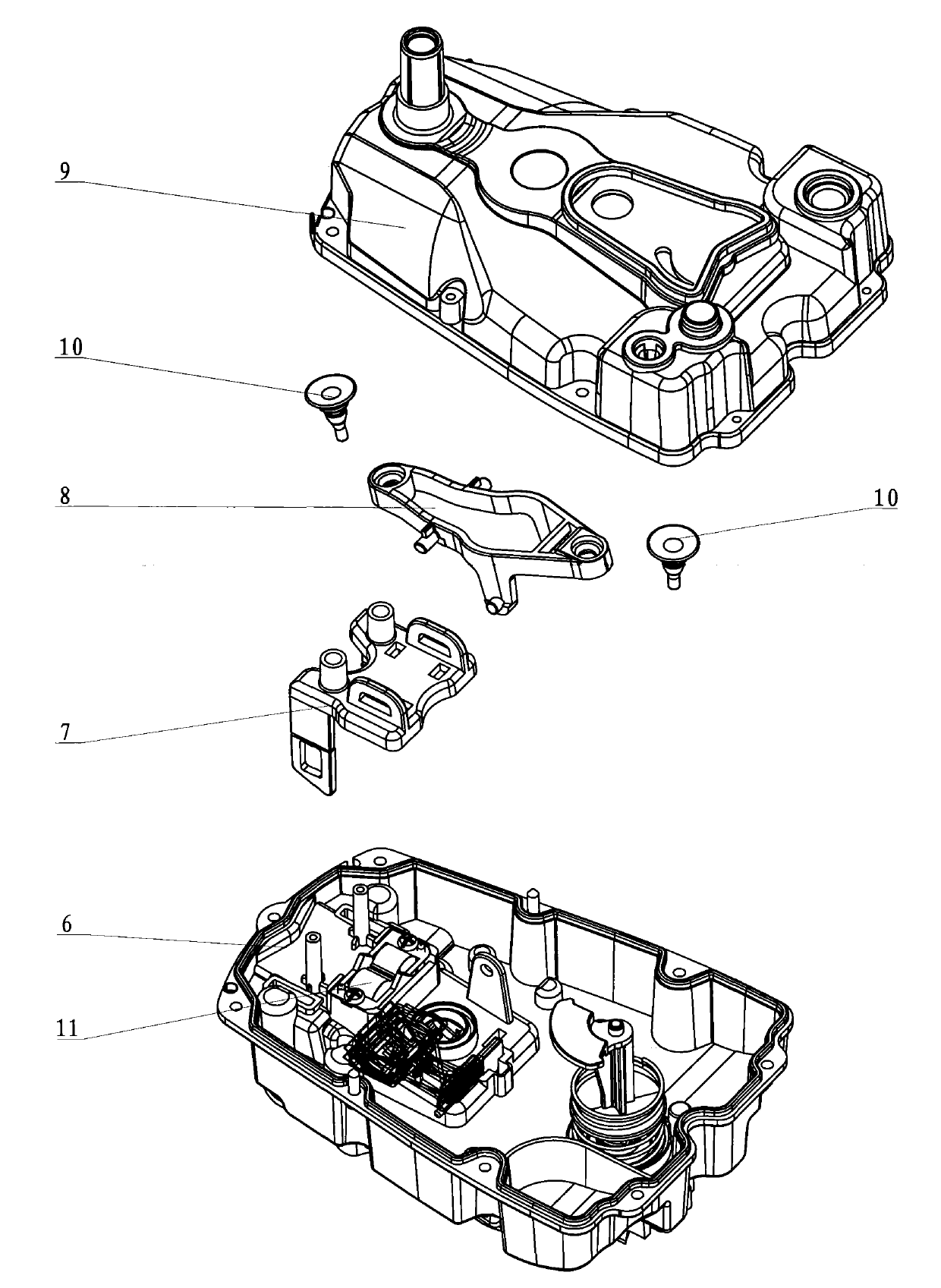

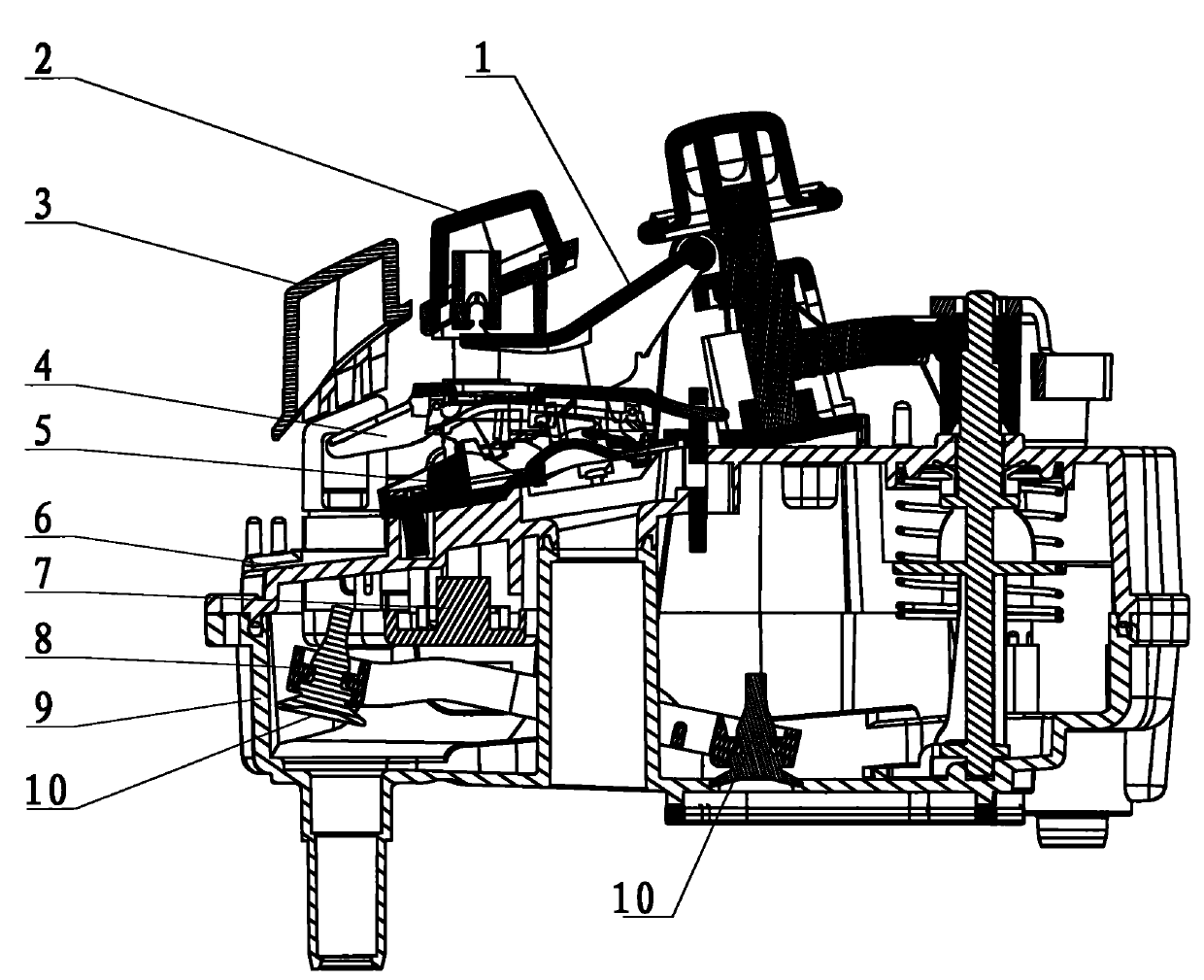

[0013] The structure diagram of the present invention is as figure 1 , 2 As shown, the water stop mechanism of the instant electric kettle of the present invention includes a steam box cover 6, a drive rod 7, a lever 8, a steam box 9, a sealing ring 10, and a shrapnel 11, wherein the steam box cover 6 is mounted on the steam box 9, one end of the lever 8 is hinged on the steam box cover 6 through a hinge shaft, and the lever 8 is connected to the guide groove on the drive rod 7 through a pin shaft, so as to provide downward or downward power for the drive rod 7 respectively. The shrapnel 11 is connected with the driving rod 7, and two water-closing sealing rings 10 for sealing the water outlet and the drain on the steam box 9 are respectively fixed on the two ends of the lever 8.

[0014] In this embodiment, a switch 4 is arranged above the driving rod 7, and the switch 4 is connected to the water stop button 3 arranged above it. In addition, a connecting rod 1 for driving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com