Automatic quantitative tea feeding distribution system

A distribution system and tea technology, applied in the direction of tea processing before extraction, can solve the problems of low production efficiency, broken tea leaves, lack of quantitative conveying tea on-demand distribution function, etc., to achieve the effect of improving production efficiency and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

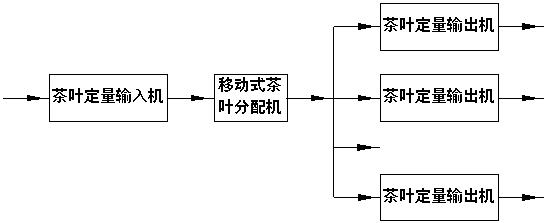

[0022] The structural block diagram of the tea automatic quantitative feeding distribution system is as follows: figure 1 shown in figure 2 In the shown embodiment 1, the automatic quantitative feeding distribution system for tea leaves includes a central controller 16 for conveying, weighing, and distributing tea leaves, and controlling the operation of the automatic quantitative feeding distribution system for tea leaves. The described automatic quantitative feeding distribution system for tea leaves includes a There are tea quantitative input machine 1 and three tea quantitative output machines 2, and the central controller is arranged on the tea quantitative input machine. Both the tea quantitative input machine and the tea quantitative output machine include a frame 4 and a conveyor belt 5 arranged obliquely on the frame. The low end of the conveyor belt is the feeding end, and the high end is the discharging end. The main motor is controlled by the central controller. ...

Embodiment 2

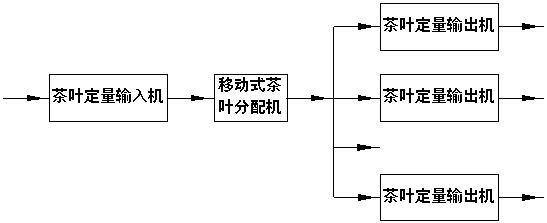

[0026] The structural block diagram of the tealeaves automatic quantitative feeding distribution system of embodiment 2 is as follows Figure 4 As shown, there are 5 tea quantitative output machines, which are respectively arranged on both sides of the track. A uniform material device 12 is provided above the middle part of the conveyor belt of the tea quantitative input machine and the tea quantitative output machine. The length of the conveyor belt is adapted to the width of the conveyor belt, and the return wheel is provided with a dialing device 15, and the dialing direction of the dialing device is opposite to the feeding direction of the conveyor belt (see image 3 ). The equalizing plate and the belt surface of the conveyor belt are set in an inclined state, the inclination direction of the equalizing plate is consistent with the feeding direction of the conveyor belt, and the angle between the equalizing plate and the conveyor belt is 140 degrees. The feeding device ...

Embodiment 3

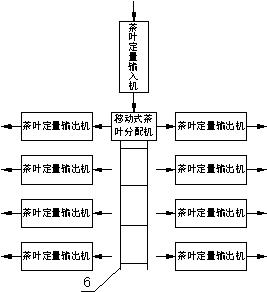

[0028] The structural block diagram of the tealeaves automatic quantitative feeding distribution system of embodiment 3 is as follows Figure 5 As shown, the track is parallel to the length direction of the tea quantitative input machine, and there are 8 tea quantitative output machines, which are symmetrically arranged on both sides of the track. The weighing mechanism is an electronic weighing mechanism, and the electronic weighing mechanism is equipped with a weight signal generator, which is connected to the central controller; the material shifting device is an arc-shaped material with an arc-shaped cross section made of stainless steel plate , the length of the arc-shaped shifting plate matches the width of the conveyor belt, and the direction of the end of the arc-shaped shifting plate is opposite to the direction of rotation of the return wheel. All the other are identical with embodiment 2.

[0029] When the tea automatic quantitative feeding and distribution system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com